Equipment innovation is a huge factor in making agriculture more efficient. Always has been and likely always will be. However, to truly enhance efficiency while also cutting costs, the innovation has to involve more than bells, whistles and increased horsepower.

One of the most publicized events at Agritechnica in Hannover, Germany, this year was the unveiling by John Deere of its new dual-axial rotor harvester. While Deere touted all the efficiency enhancements with the new design, it was all a little like going back to the future. There were twin rotor combines 40 years ago and they weren’t green.

Read Also

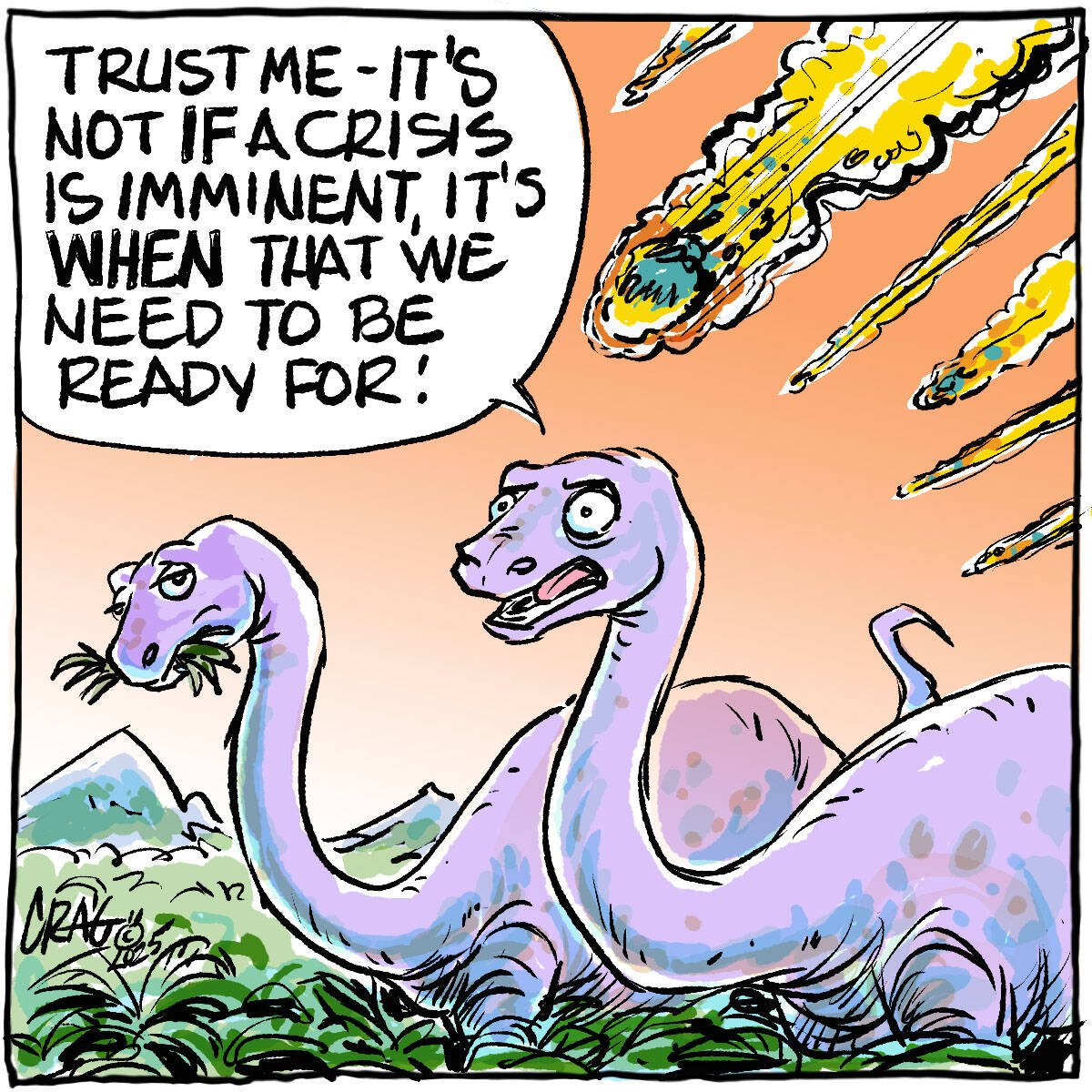

Proactive approach best bet with looming catastrophes

The Pan-Canadian Action Plan on African swine fever has been developed to avoid the worst case scenario — a total loss ofmarket access.

Deere says it will have demo machines in the field by next fall. When the X9 combine hits the market, you have to wonder what the price point will be. There’s a good chance it will be a million dollar combine. Will the extra capacity actually be worth the enormous price tag?

While autonomous operation is a major trend and seems destined to gradually become practical, many farmers trying to turn a profit in a difficult marketplace can cut their costs by running older equipment rather than the newest and shiniest.

What would you rather have?

- A combine that’s only one or two years old with a bit of warranty left?

- Two combines that are five years old each with about 1,000 separator hours?

- Three 10-year combines with about 2,000 hours on them?

Sticking with John Deere and going from advertised prices, the first option means a machine valued at more than $600,000. Two five-year old combines might run you around $500,000 and you could get three decade-old combines for around $400,000.

The newer models will have more capacity and should be more reliable with reduced repair bills, but if you have the people to run them, you’ll cover more acres with two or three older combines than one new one. It also gives you more flexibility if there’s a reason to have combines running in different fields or different crops at the same time.

For full disclosure, I run combines that are a little more than 20 years old. It is possible to find older combines with a lot fewer hours than the typical 200 hours per year use pattern.

Labour is often cited as the reason for going with a newer combine rather than two or three old ones. However, there are many semi-retired and retired people in our towns and cities that can quickly learn to run a combine even if they’ve never done it before. What’s more, they often enjoy it.

In regions where grain is often harvested tough or even damp, many producers tout the benefits of having a good grain dryer rather than an additional combine. Another strategy is to grow a mix of crops with different maturities to spread out the harvesting window.

Having the newest and biggest equipment is appealing, but in many cases it isn’t the approach for optimizing returns. The price tag on new equipment keeps escalating at a time when commodity prices and overall returns are soft.

Not surprisingly, sales of new equipment are dropping. Interestingly, declining sales are also evident in the U.S. market, where billions have been paid to corn, soybean and wheat farmers to compensate for the American trade war with China.

Good, late-model used equipment is looking a lot more practical than the newest stuff.