Alberta field tour gives maltsters and brewers a chance to learn about the origins of their most important ingredient

RED DEER COUNTY, Alta. — If there are no farmers, there is no beer.

With that in mind a special tour organized by the Alberta Barley Commission and the Canadian Malting Barley Technical Centre showed local and international maltsters and brewers where it all starts in the field.

Established varieties like AC Metcalfe and CDC Copeland were shown but central Alberta farmers also showcased newer two-row barleys like AAC Synergy, CDC Bow, AAC Connect, CDC Fraser and Lowe.

“Activities like this can really bring together the entire value chain and highlight the potential benefits of new varieties,” said Geoff Backman of the Alberta Barley Commission.

Read Also

Farming Smarter receives financial boost from Alberta government for potato research

Farming Smarter near Lethbridge got a boost to its research equipment, thanks to the Alberta government’s increase in funding for research associations.

Metcalfe and Copeland are still the most popular varieties, but they are 20 years old and new types may offer some agronomic as well as improved malting characteristics.

“There is a lot of potential benefit to move toward some of the newer varieties for everyone. There are more opportunities for farmers for higher yields with greater disease resistance and other agronomic potential. There are benefits for maltsters because higher yields of malt barley provide a more stable supply. There are benefits for brewers as well because some of the newer varieties have higher extraction rates,” he said.

At Antler Valley Farm near Innisfail, Alta., malt barley is a major crop for the 4,000 acre farm established in 1890.

Run by Wayne McAllister and sons Wade and Scott, malt barley is part of a four-year rotation.

“In our area, we can grow great malt because we can keep the protein levels down. It is the same reason we don’t grow great wheat. We grow lots of yield. We tend to grow CPS and go for the feed market,” said Scott.

Copeland and Synergy are the main varieties. This year they seeded Copeland on May 9 at 3.5 bushels per acre.

“It is a bit heavy, but we like to have more plants per sq. foot and that way if it is a dry year, the crop matures more evenly,” said Wade.

Copeland has between nine to 10 percent protein, while Synergy is around eight percent. Synergy is not as tall so there is less straw for them to deal with.

“We are moving the farm more into Synergy acres. We have Copeland for a Sapporo contract with Canada Malt,” said Scott.

They have been direct seeding for the last 20 years and have seen soil organic matter improve from four to eight percent. They use 55 pounds of nitrogen and a third of their acres receive potash each year. Tissue samples show nutrition is adequate.

All the barley is straight cut and if necessary it will go into a new grain dryer. There have been major snowfalls four years in a row at harvest time and this can save a crop.

Some smut appeared this year but it is not enough to affect the final product. The disease moves throughout the plant and by the time it is noticed it is too late to treat, said Chris Spasoff from Syngenta, technical barley lead.

“This year seems to be a worse year for smut and certainly in central Alberta,” she said.

The Hamill family of Penhold, Alta., has a two-pronged approach. They grow Connect, Synergy, Lowe and Newdale. Part of the crop is directed to their other company, Red Shed Malting, established in 2014. They produce about 250 tonnes of malt per year for the craft brew industry, which is often looking for alternative barley varieties for different flavour and aroma.

Newdale and Lowe are being produced at small levels. About three to five percent of barley acreage on the Prairies for the last 10 years was seeded to Lowe.

As a farmer, John Hamill likes Newdale because it does not lodge as much as some other crops. With heavier rains and richer soils, this can be an issue in central Alberta.

“We started growing Newdale and we really liked it because it was one of the barleys that would stand up in our field and it wouldn’t lodge,” he said.

It yielded as much as other crops and malts well. Brewery acceptance has been good because of the flavour. The Hamills are also trying Lowe because it has good disease resistance.

“With all of these varieties you have to try them on your own farm because you don’t know what it is going to grow like,” he said.

AC Connect is another variety that works well for them. It has good standability and a good disease package. Its malt qualities are similar to Metcalfe but Connect has a higher yield. The Hamills tested it against Newdale and did not see much difference although Newdale barley had a bushel weight of 54 lb. and Connect was 58 lb.

“It looks like one that might take over from Newdale. It just depends on our customers and brewers if they want to have Newdale malt anymore,” John said.

Canada Malt and Prairie Malt have contracted this variety. A large maltster in China is also trying Connect so there is hope that demand for this variety might build.

At Lenz Farms at Bentley, Alta., Jason Lenz once grew feed varieties but switched to malt. The past chair of the barley commission and director with the Alberta Wheat Commission, Lenz has been willing to try new malting varieties on a test basis to see how they perform in his climate.

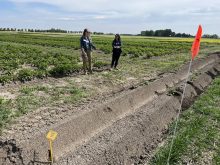

This region receives a lot of rain and in the early 1980s, the family added about 13 kilometres of tile drainage. Tile went in from 30 inches to three feet deep to help carry away excess moisture.

“We are farming way more acres because of that,” he said.

“Every year it is a good return on investment because some years it would just be yellow and there would be standing water,” he said.

This year he planted Bow, registered in 2016, and Fraser, registered in 2017, side by side as a test.

Last year, Bow yielded 75 bushels per acre. Yield was diminished by drought but this year the farm has received 240 millimetres of rain in a timely fashion so he anticipates better production.

Bow was seeded at a rate of 180 lb. per acre and Fraser was about 170. He uses variable rate fertility and goes from 50 to 75 lb. of nitrogen based on soil tests.

Some of the Lenz barley has been shipped to China, where it is being tested for quality.

Canada Malt is also testing Fraser, said company spokesperson Bob Chappell. The company buys about 550,000 tonnes of malt barley that is processed at Calgary, Thunder Bay and Montreal.

Only small batches of Fraser have been run because there were only about six people growing it.

Many of these new varieties work well for craft breweries, as well as for large companies.

“We are really hoping that Bow or Fraser will turn out to be a Metcalfe replacement,” Chappell said.