The protein menu is rapidly diversifying, but consumers are urged not to forget the more conventional sources

Whether it’s a steak, soy burger, cricket smoothie or culture-grown patty, protein is an essential part of the human diet.

Plant-based proteins are common, Bob Tyler, a University of Saskatchewan food and bioproduct sciences professor and Ag-West Bio chair, said during the organization’s annual meeting in Saskatoon June 27.

“One of the things that fascinates me is you’d think we’d never eaten plant protein until about two years ago,” he said.

Wheat, barley, oats and even beans with pork are all longstanding sources, he added.

Read Also

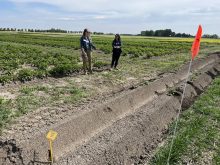

Farming Smarter receives financial boost from Alberta government for potato research

Farming Smarter near Lethbridge got a boost to its research equipment, thanks to the Alberta government’s increase in funding for research associations.

Attention to protein was piqued further by the release of Canada’s new food guide in January.

The guide was developed solely by nutrition experts without input from industry, said U of S nutrition professor Gordon Zello. Two sections from former iterations — milk and milk products, and meat and meat products — now are consolidated into a single “protein” category, which covers a quarter of the guide’s plate. Most Canadians are getting enough.

“For a 70 kilo person, you will need about 56 grams of protein a day. That’s all we need,” Zello said.

“We’re taking in between 80 and 100 grams per day.”

A large egg contains about six grams of protein.

The question of where we get our protein has led to increased scrutiny of animal agriculture, advocacy for plant-based diets and novel sources. Products such as the Impossible Burger are selling briskly.

“What’s new, what’s really new in plant protein? Well, of course the level of interest is unprecedented, there’s no doubt about that,” Tyler said.

The federal government is investing $153 million in protein research and development through Regina-based Protein Industries Canada (PIC), one of five innovation superclusters across the country.

Tyler, who is just completing a stint as interim chief technology officer for the organization, said one of PIC’s challenges is to fund development of new uses for crops and their byproducts to add value.

While plant-based proteins may be in public favour, animal sources face negative pressure. Marketing campaigns question practices such as the use of hormones, and some groups criticize the environmental sustainability of animal agriculture as a whole.

Deborah Wilson, senior vice-president of BIXCo Inc., which offers data tools to allow animal traceability from farm to consumer, said the criticism hit hard.

“(Beef producers) are very proud people,” said Wilson, who is a 40-year beef producer.

“They work very hard to take care of their animals; all of a sudden everything they’re doing is being called into question.”

Wilson sits on the Canadian Roundtable for Sustainable Beef (CRSB), and she said initially the situation “looked hopeless.” Around the table sat animal rights activists, a marketing executive from A&W and representatives from organizations such as the Nature Conservancy, Ducks Unlimited and the World Wildlife Fund.

“Five years later, we have a sustainable beef framework. The whole program is fully audited,” Wilson said.

The program has been praised as a model for other agricultural sectors to emulate, she added. Restaurant chains such as MacDonald’s, Original Joe’s and Cactus Club support it, and consumers can look for the CRSB Certified Beef Sustainability logo on products.

This consumer trust offers a premium.

“We’ve been averaging anywhere from $18.25 to $18.50 per head per operation,” Wilson said.

“So, it’s not as big a volume of money that you might like to see for a cow-calf producer, but nor does your audit cost as much. But for a feedlot, that’s a significant amount of money.”

Kelly Hagen, chief operating officer for Entomo Farms, raises much larger numbers of much smaller livestock — 10 million head of crickets in its 5,600 sq. metre facility near Toronto.

As North America’s largest producer of crickets and mealworms for human consumption, Entomo ships to dozens of companies in eight countries. Its products appear in protein bars, chips, pastas and crackers — as well as spiced whole-cricket snacks served at the Ag-West Bio meeting.

“As the population grows to more than nine billion people, we can’t continue to feed them protein the way we do today,” she said, emphasizing that more sources are needed to supplement existing supplies.

Nutritionally, crickets resemble meat with all essential amino acids and the added bonus of fibre and very high levels of vitamin B12. Feed conversion is excellent, at 1.5 kilograms of feed to produce one kilogram of crickets. They require little space or water and produce no methane.

Marketing insect-based foods is easier than one might think, Hagen said. Most of their crickets are roasted, dried and ground into powder, so the squeamishness factor is not an issue. The big challenge is to make the product stand out. Enticing a big brand to put its own name on the product, as President’s Choice did with the company’s new cricket powder in 2018, provides a big boost.

While most protein producers are focusing on field and farm, Matt Anderson Baron’s vision for cellular agriculture is a facility much like a brewery — a series of bioreactors where meat cells grow in tanks of nutrient solution.

Anderson Baron, lead scientist and co-founder of biotech startup Future Fields in Edmonton, faces a common question: why grow meat in tanks when animal agriculture has been doing it for thousands of years?

“Typically, we answer that question with another question: ‘how do we feed 10 billion people?’ ” he said.

“People really love meat, or more specifically, North Americans love meat. The average family of four consumes a hundred chickens, four pigs and one cow per year.”

Meat consumption has increased globally over the last 50 years — a trend that is expected to continue as people get richer.

The first cultured meat burger, created by a Dutch team, cost about $300,000 to produce, Anderson Baron said. That price has come down to about $2,000 per pound, offering hope that cultured meat can be a viable product, if several hurdles can be cleared.

An affordable growth medium must be developed and produced in large quantities. A “scaffold” is needed that can mimic muscle tissue so the cells don’t simply grow in a thin sheet. Finally, cultured meats will require purpose-built bioreactors for mass production.