Running older equipment certainly has its challenges. Sometimes nagging little problems can be fixed. Other times, you just live with the quirks and learn to work around them.

The farm has a lot of equipment refinements and modifications. Some probably look silly, but they work.

We like our seed cart, but the loading auger is hard to use. The previous owner added an extension on the bottom for reaching under trailers. Unfortunately, this makes the auger difficult to position in some terrain and it also causes bounce during operation.

Read Also

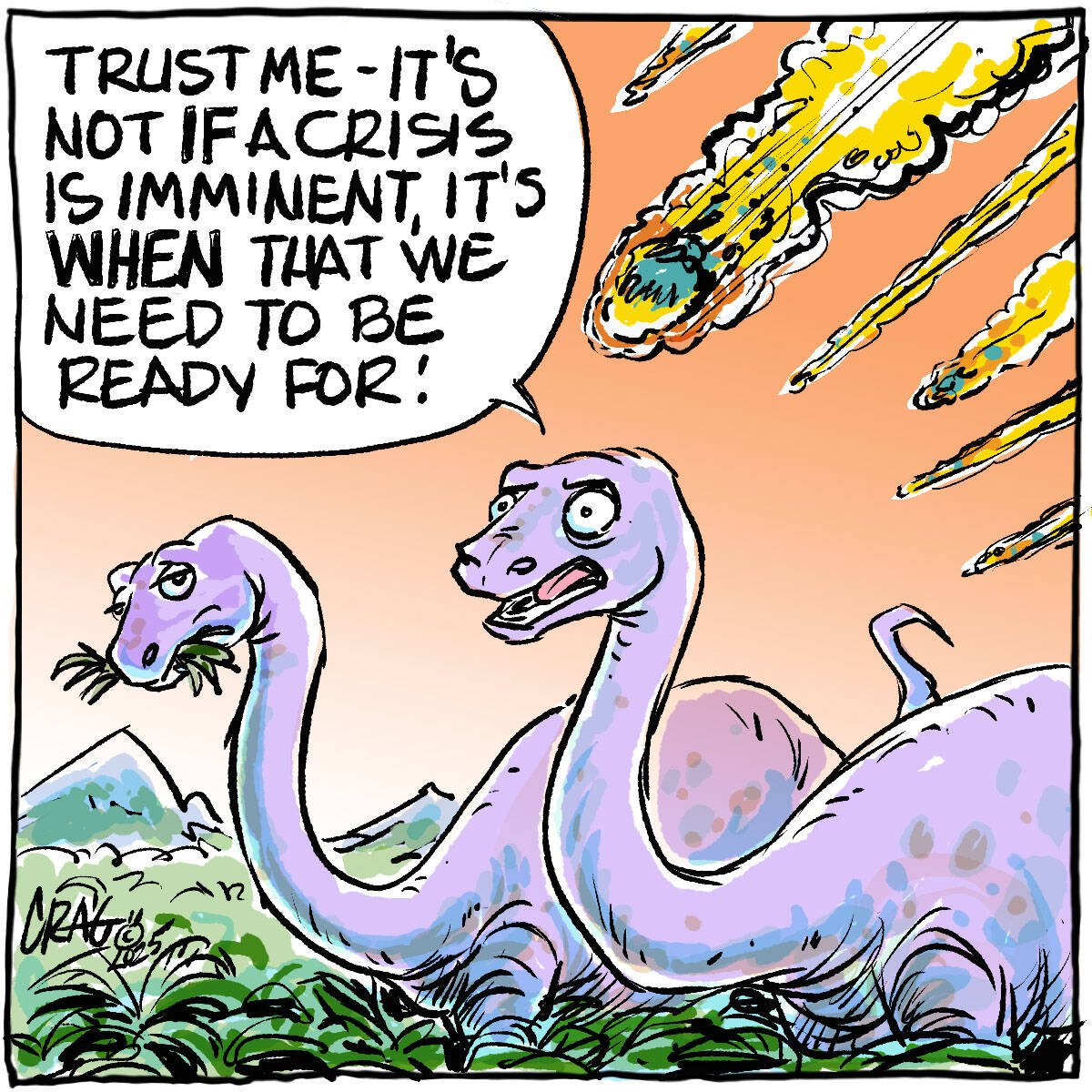

Proactive approach best bet with looming catastrophes

The Pan-Canadian Action Plan on African swine fever has been developed to avoid the worst case scenario — a total loss ofmarket access.

We’ve gone to loading the cart with a Batco grain conveyor. Yes, we have to move the conveyor from field to field separately from the seed cart, but it’s easy to position and it moves a much greater volume of product, reducing the time needed to fill. As well, it’s much easier to clean out when switching between seed and fertilizer.

We’ve actually removed the auger from the side of the grain cart making it easier to position the Batco underneath the cart for emptying the tanks.

Most seed carts have augers or conveyors that work very well. In our situation, a separate conveyor has been a time saver.

I’ve become a big fan of kill switches on equipment. Often there’s something drawing electrical current even after the key is turned off. A kill switch can prevent a dead battery and reduce the risk of fires while equipment is in storage.

Our mid-1990s seeding tractor, a Case 9370, suffers from battery drain if unused for a significant length of time. In fact, the instruction manual actually warns of this. It’s the next piece of equipment destined for a kill switch.

On our late 1990s Massey combine, the electronic display on the dash often fails to turn off with the key. A kill switch was a lot easier and cheaper than trying to fix or replace the display.

Something as simple as door handles can drive you crazy. We have a mid-1980s tandem that we’ve turned into a water truck. Both outside door handles are broken and truck repair folks have been unable to locate replacements, either new or used.

To open the door, you need to insert your arm through the little swinging window and reach for the inside handle. Of course, you must never latch the window from the inside or you have a big problem the next time you need to enter.

Last fall, this water truck was equipped with a pump and left near fields being harvested in case it was needed for a fire. On the outside of the door we printed entrance instructions, fearing a neighbour would need the truck in an emergency only to be stymied by broken door handles.

Once we get through seeding, we’ll have to start working on the long list of repairs needed on various pieces of equipment. The mid-70s tandem used for phosphate fertilizer has something wrong with the split shift. You can use only the bottom four gears. Good thing the farm isn’t spread out very far.

The main tandem has an annoying air leak, meaning extra wait time before the air brakes will release. The seeding tractor needs a new set of batteries. The little bucket tractor appears to have a power steering pump problem.

Every farm will have similar stories on repairs, modifications and equipment quirks. For farms running older equipment, you almost need special operating manuals.