This is a year when side-banding nitrogen next to the seed row could prove costly for many growers.

In a dry spring like this one, plant establishment has no doubt been compromised in many instances and there will likely be yield losses directly attributable to side-banding.

Typical of many growers, I use a side-band system and this year I regret it.

The fertilizer goes in the bottom of the furrow while the seed is placed above and to the side. If moisture conditions are good and particularly if it rains after you seed, the system works just fine.

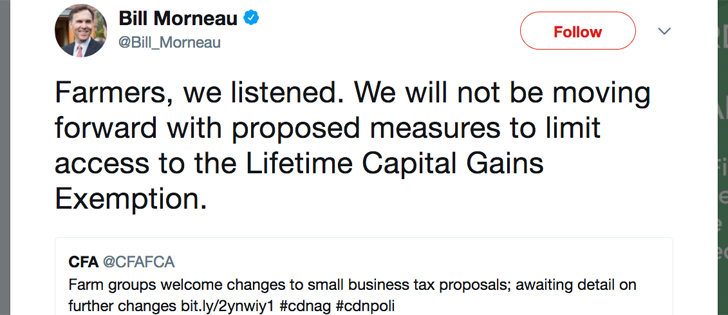

Read Also

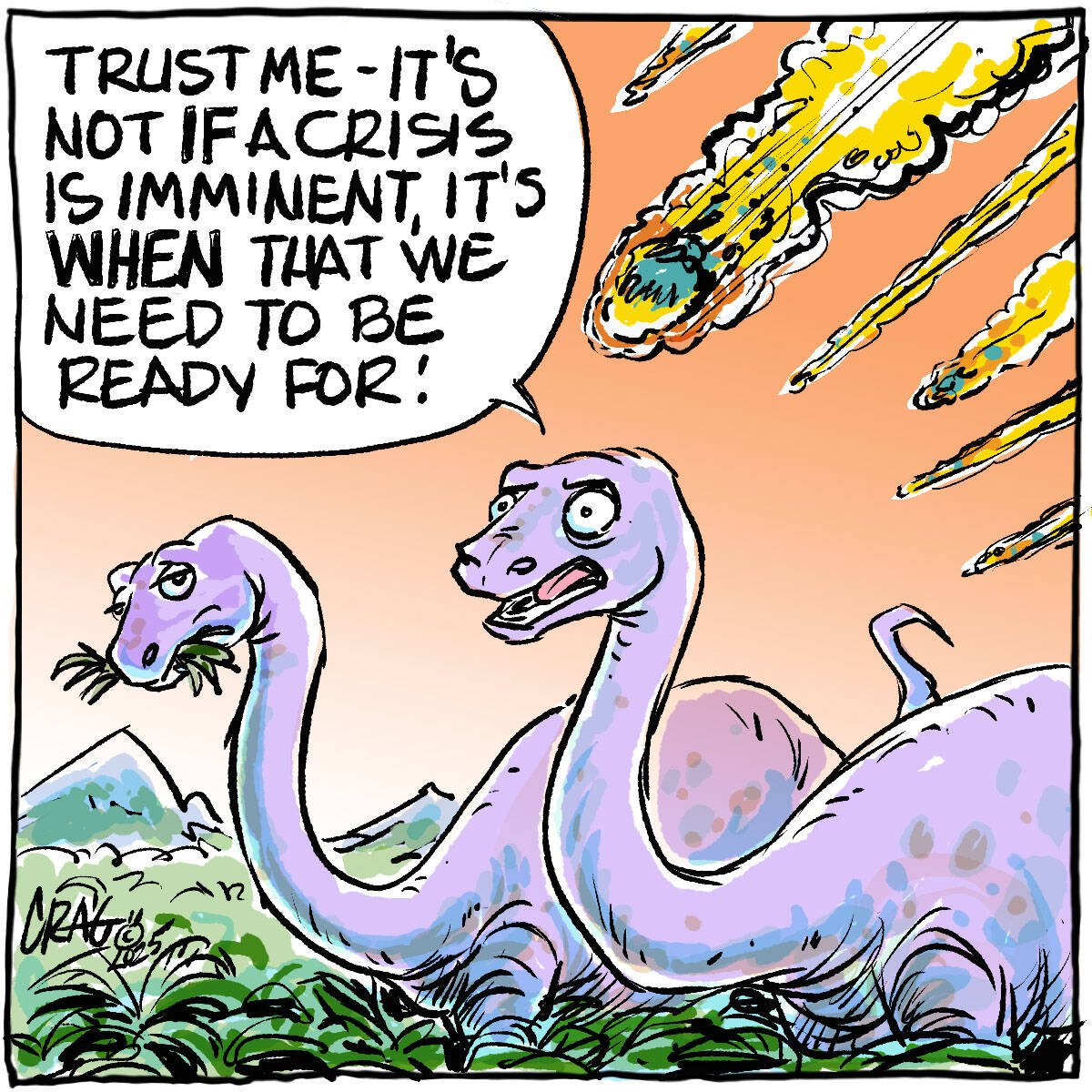

Proactive approach best bet with looming catastrophes

The Pan-Canadian Action Plan on African swine fever has been developed to avoid the worst case scenario — a total loss ofmarket access.

In a dry spring, the system has many drawbacks and those are evident this year. My emergence isn’t as good as neighbours who use different systems.

With side-banding, the soil opener is wider to accommodate both seed and fertilizer and the furrow may not close as well around the seed. Furthermore, the soil is fractured below the seed and it dries out faster.

Some mixing of seed and fertilizer seems to inevitably occur. Too much fertilizer close to the seed is toxic, particularly in dry conditions.

Even if seed and fertilizer separation is maintained, the fertilizer draws a lot of moisture.

In single shoot systems, producers need to be aware of restrictions on how much fertilizer can be placed with the seed. The safe level varies according to soil moisture levels, soil texture, seed row spacing and seed type.

The wider the row spacing, the more fertilizer is concentrated in each row. Canola, mustard and flax are more sensitive to seed-placed fertilizer than cereals.

Producers move from single shoot systems to double shooting with sidebands to provide separation between the seed and fertilizer, in-creasing the amount of fertilizer that can be safety applied. This year, it will bite many of us.

In the past decade, there has been a major move to systems where the nitrogen is placed in a separate row. Seed placement is improved and the nitrogen is far enough away that it can’t cause seedling injury.

As well, the nitrogen can be placed deeper where volatilization losses are less likely.

Phosphate, at safe levels, still must be placed with seed because it’s relatively immobile and plants need it right after germinating.

Farmers seed different crops at different times at different depths into fields with different cropping histories and crop residue so comparisons are difficult. Overall however, this won’t be a good year for sideband systems.

Competition between seed drill manufacturing companies is intense and there are all sorts of considerations involved when producers buy a different seeder. Moving from one system to another is a big decision, but this dry spring is likely to alter producer opinions.

Nitrogen can be banded before seeding or it can be added within a growing crop, but the vast majority goes into the ground with the seed. It works well as long as you can provide good separation between the two.

Products exist to make nitrogen safer for placement with the seed and near the seed row, but they come with a significant cost. And this still doesn’t solve the seedbed issues of side-banding.

Recent wetter than normal springs have been occurring and perhaps will resume.

However, many producers will long remember this dry spring and will likely gravitate to seeding systems that keep the nitrogen a safe distance from the seed row.