Sobkowich is executive director of the Western Grain Elevators Association.

KVD stands for kernel visual distinguishability. Simply put, KVD means being able to tell what class grain falls into by looking at it.

Grain is organized into classes such as Canadian Western Red Spring (CWRS), Canadian Western Amber Durum (CWAD), Canadian Western Red Winter (CWRW), etc. Different classes have different values and pricing structures.

Only certain varieties are eligible for a particular class, and KVD means that a trained person can differentiate between the classes through visual inspection. Any grain that contains an excess of varieties outside the intended class is downgraded to the Canada Feed grade.

Read Also

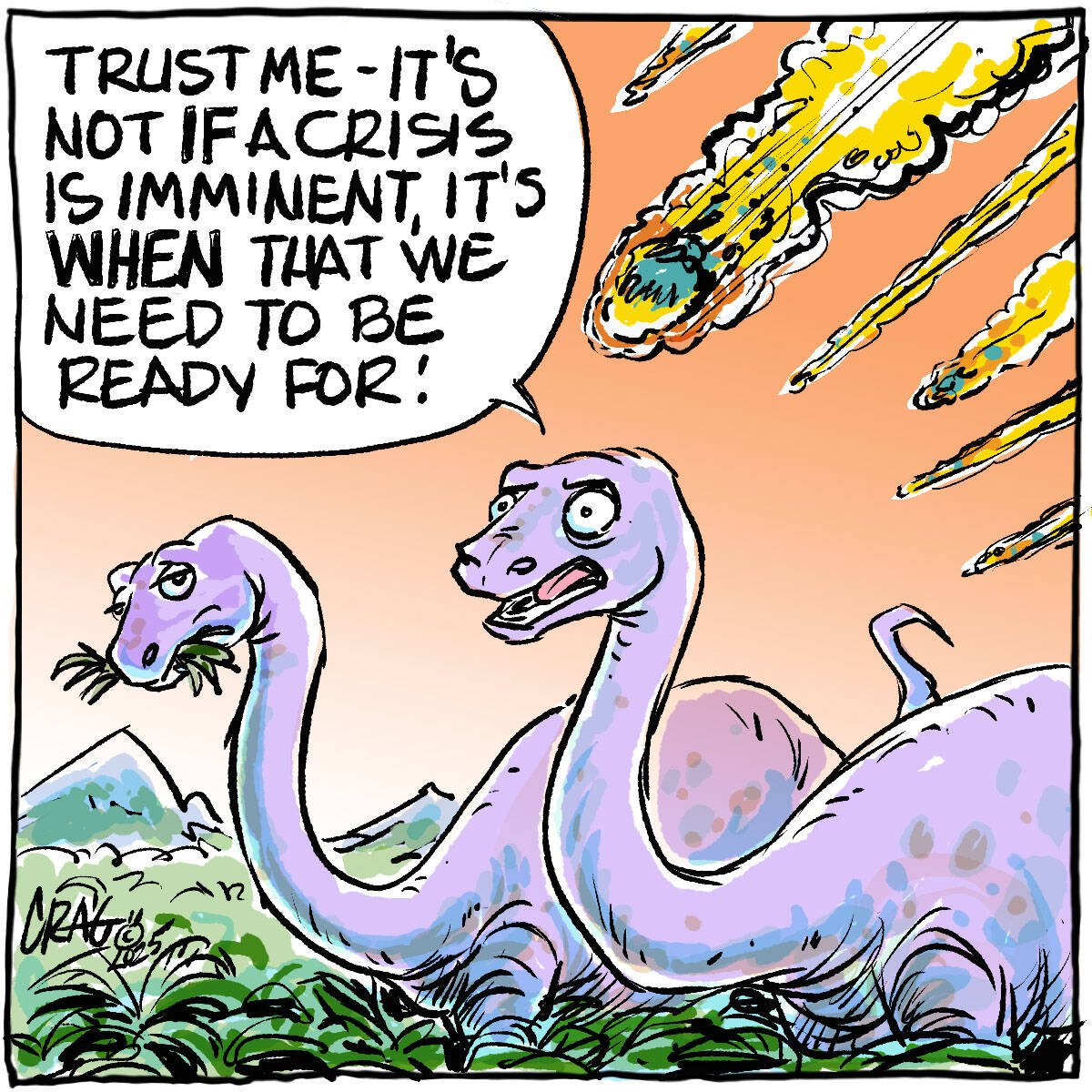

Proactive approach best bet with looming catastrophes

The Pan-Canadian Action Plan on African swine fever has been developed to avoid the worst case scenario — a total loss ofmarket access.

KVD is a consideration used by the Canadian Food Inspection Agency when deciding what varieties should be registered. Although a variety may meet all the required quality, disease and agronomic factors to qualify for a certain class, it might not be registered because it looks like a different class (a CWRW variety that looks like CWRS, for example).

KVD can restrict the registration of varieties that may have certain advantages for growers or the end use customer.

It is important to draw a distinction between KVD for establishing the class and visual inspection to determine the grade.

Once the class is established, the grain is assigned one of several grades through the application of degrading factors.

These determine if the grain makes a 1, 2, 3 or feed. They have to do with the amount of mildew, smudge, sprout damage, broken kernels and wheat of other classes present in the grain.Â

Removal of KVD for establishing class has nothing to do with this system. When a farmer delivers his grain, the elevator staff determines that it looks like a certain class, assigns a grade and offers a price.

At that point liability is normally transferred from the farmer to the grain handler. The handler is now responsible for that grade through the system to the end user or to the Canadian Wheat Board at port position. In addition grain is visually graded on unload at the terminal and on load out to a vessel.

The biggest problem with removing KVD is the obvious one. It exists to protect the farmer because it allows settlement at the time of delivery.

It protects the grain handler because the certificate final is based on a visual grading system. It protects the marketer by giving assurances that the customer is receiving what he ordered. It protects the end use customer by providing confidence that they are receiving grain that meets their processing requirements.

If we relax or remove the KVD requirement in a hasty manner, the opportunity exists for accidental or intended mingling of varieties.

The associated losses may be strictly financial and can be over $1 million on a vessel shipment, but may also be in lost customer confidence.

The technology does not exist to rapidly, accurately and cost effectively identify the variety when the farmer delivers into the system.

When this technology becomes available, it will reduce the farmer’s exposure to liability, since handlers would be able to test in the driveway and give the farmer the right grade or price based on the test.Â

Until then, the system being contemplated will require that the farmer be exposed to liability after delivery should a problem be found in a rail car, elevator bin or hold of a vessel. This is an important point. The removal of KVD means that exposure to liability for the farmer will not end when he gets a cash ticket or when a price is established.Â

The removal of KVD for the major classes of wheat presents myriad policy and operational issues that must be addressed and resolved before the changes come into effect, such as:

- The liability and risk impact on industry participants including the Canadian farmer.

- Producer declarations.

- Remediation solutions for contaminated stocks at country, rail, terminal and loaded vessels.

- Sampling and testing requirements for all system participants including farmers, and nature and magnitude of penalties.

- Technology and the evaluation of testing equipment.

- Auditing requirements and protocol.

- Requirements for issuance of the Certificate Final.

- Producer car loading protocols.

- Additional system and producer costs.

The government has announced that KVD will be removed by 2010. The industry has taken the proactive step of establishing a group known as the Industry Committee on Removal of KVD.

This committee, which includes producers, is working to establish a system to replace KVD. While 2010 is an ambitious timeline, we are optimistic that it is achievable.

KVD exists for the protection of all industry participants. Like it or hate it, right now it is the only way for us to know what we are handling and to make appropriate segregation decisions.

We understand the need to allow for development of new varieties to meet the needs of different segments of the industry; grains for ethanol production and livestock feeding for example, and we are supportive of the changes being proposed to KVD for 2010.

It is important that the government consider a greater role in the development of testing technology to reduce the farmer’s exposure to liability after the fact.

It is also important that the government give the industry enough time to develop a system to replace KVD and stay with the 2010 timeline for removal.

We simply want to ensure that farmers, grain handlers, marketers and customers are not put in a position where they are unable to appropriately manage the risk of the change at a reasonable cost.