Bin monitoring system allows producers to keep an eye on their assets right from their computers or smartphones

Grade loss because fans weren’t turned on in the bin is an indefensible mistake, especially when there are so many high-calibre bin monitoring systems available to grain growers.

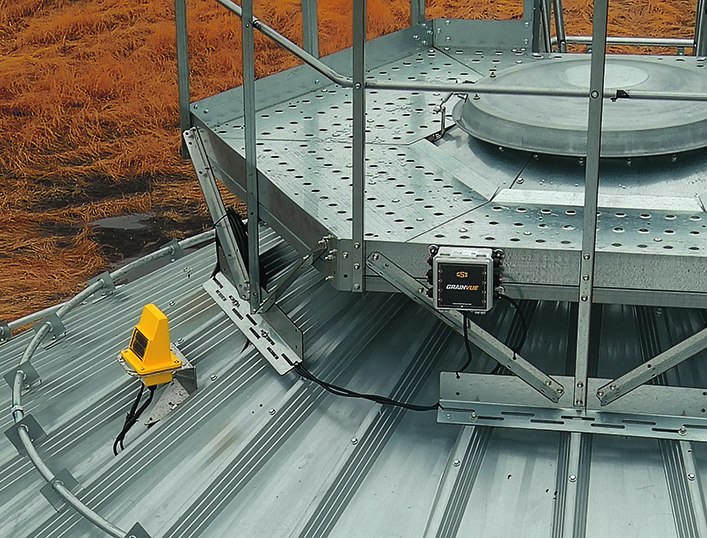

GSI is one of the largest manufacturers of monitoring systems and it recently announced upgrades to its GrainVue system, said Greg Trame, director of technology sales. In a phone interview, Trame said GSI dissected the system to find areas where newer technology could improve performance.

The revised model is a digital cable-based system that uses conventional digital cable sensors hanging in the bin. Different types of sensors are available, depending on needs and bin contents.

“We have two versions. One sensor only measures temperature. The other style measures temperature and humidity, allowing us to calculate moisture,” Trame said.

“From there we are an entirely cloud-based system. We gather data at the bin and send it up to our data cloud. Customers interact with that data through the mobile device of their choice: cell phone, iPad, laptop or computer.

“Each customer has their portal, which lets them see all the information that’s been gathered at the bins.”

Each unit includes a weather station that documents ambient temperature and humidity at the outside wall of the bin. This information is essential if the farmer wants to control fans and heaters remotely. Weather data is also necessary if the farmer wants automated fan control.

For example, if trying to lower grain moisture inside the bin, the fans shouldn’t run when relative humidity is 95 percent.

“Low-temperature heaters can be incorporated into the plan to aid in the drying process. GrainVue can be set up so the customer turns control of fans and heaters over to use if he can’t manage it himself for any reason,” said Trame.

“Normally there’s only one human interaction. Once the bin is full, the farmer decides whether he wants manual remote control of the fans and heaters or automatic control. That switch is located on the control panel. Everything else is handled by the device.

“In the automatic mode, the farmer sets up ranges of temperature and humidity and the target moisture point. The fans and heaters will turn off and on when temperature and humidity readings are within the window range determined by the farmer.

“In the smart mode, the farmer simply tells the system what’s in the bin and what are the target temperature and moisture, and then lets the system figure out how to do it.”

Trame says all this automation doesn’t mean a person can fill the bin, press a button and walk away for six months. He says the bin operator should still monitor the readings, but doesn’t have to trudge out to the bin yard when it’s –38 C. GrainVue has a variety of alerts that can automatically trigger a message to the farmer if something is going wrong.

Grain monitoring systems can’t detect grain theft in real time, he adds. It takes the sensors and algorithms up to 12 hours to identify a 1,000-bushel drop in grain level. Sensors in GrainVue are spaced four feet apart, which means four feet of grain must be removed before a theft would register. In a large bin, that theft might not show up at all.

Although price of the new GrainVue depends on many factors, Trame says the basic system is about US$6,000. Bin height and diameter are the two main cost factors. Larger bins could cost up to US$15,000.

If the system is used solely to monitor the bin, it can be solar powered. If used to control fans and heaters, it requires AC power at ground level.

Larger bins can be a challenge in terms of total cleanout. Trame says GSI makes bins up to 156 feet in diameter.

“All our sweeps have an adjustable bristle broom that runs behind the sweep. The first time the arm goes around, it will leave some grain behind. On the second lap, you see the floor really cleaned up. Does it remove every single kernel? No. Inconsistencies in the floor will always leave some product behind.

“Farmers are going away from conventional auger sweeps and buying rubber paddles that scrape across the floor to push grain to the auger. Rubber paddles do a much better job of bringing grain to the auger.

“But it still takes two or three passes to get the degree of cleanout people want. And guys will still need to get in there with brooms around the edges. Nothing else will totally clean the joint between the floor and the sidewall.”

As for catwalks, Trame says GSI has offered them for years. Seven years ago, GSI re-engineered its stairs, catwalks and other safety systems for every bin size.

“From a worker safety standpoint, people who buy the bigger bins won’t buy without all the stairs and railings and catwalks.”