The answer to the question of the future of the power source for high-horsepower tractors remains unclear.

Get ready for options and flexibility in motors going forward.

Follow all our coverage of Agritechnica 2025 here

Read Also

October proved warmer than average

We are going to take a quick look back at how October shaped up across the Prairies — are we already seeing the forecasted winter weather pattern developing?

Agco Power’s new lineup, called its Core engines, was filled out with a new eight-litre option this year for its Fendt 800 series tractors.

The engines are highly efficient, says Jarno Ratia, director, sales and marketing and project management for Agco Power, but they’re also ready to use other sources of fuel than diesel.

That could include biodiesel, hydrogen and methane, depending on what fuel the farmer can source.

Jahmy Hindman, senior vice president and chief technology officer at John Deere, pitched the idea that farmers could produce their own fuel on farm, taking up a limited amount of a previous-year’s crop to produce the next, completing an energy cycle on the farm.

New Holland showcased its T7 methane-powered tractor at Agritechnica, including the fact that it has made commercial sales. It would epitomize the ideal of energy circularity on the farm, using methane produced by manure to power the tractor.

There’s continues to be evolution in battery technology too, with John Deere showcasing its 120 HP equivalent tractor, numerous autonomous systems run on electricity, and Agco presenting a new stackable battery concept.

Hybrid systems will have small roles to play, say some of the major equipment makers, but Zoomlion says not so fast. The Chinese company showed up to Agritechnica with high-horsepower tractors and a combine – all designed around a purpose-built diesel-electric hybrid engine.

Companies say they will remain farmer-driven in the powertrains they deliver, creating flexible engines and batteries that will be ready, depending on what the market demands.

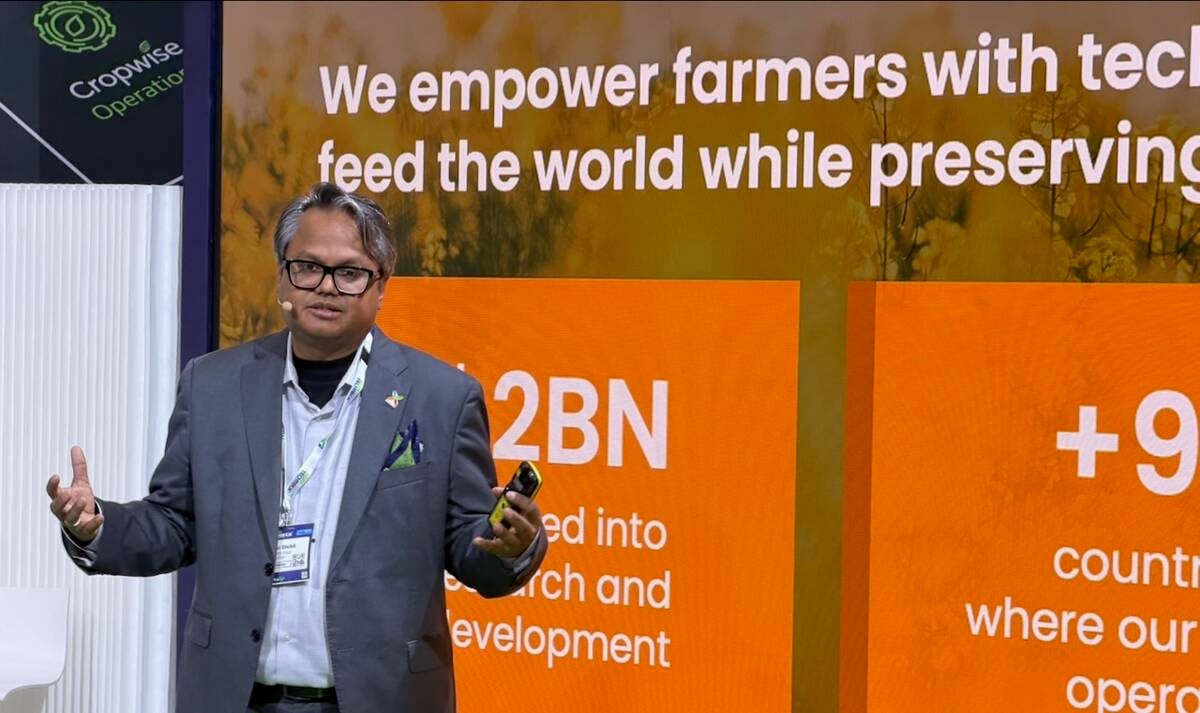

Syngenta opens up its Cropwise code to developers

Syngenta is concerned that a technology gap is growing between large and small farms and it hopes that steps like opening up its crop management platform Cropwise to third-party developers will help.

The company’s Chief Information and Digital Officer Feroz Sheikh announced the new direction at Agritechnica.

The company says that the Cropwise open platform “offers the opportunity to leverage Syngenta’s AI and machine learning capabilities and real-world agronomic data, to offer their solutions at an unprecedented rate.”

Syngenta’s display also had a Canadian connection, with the company heavily promoting its Interra Scan product, a soil-sensing system.

Interra Scan is private label brand of the Ontario-developed SoilOptix company. While Syngenta has rights to the product in Europe, the processing of the data is still done by the Soil Optix team and servers in Tavistock, Ont.

SoilOptix sensors measure gamma radiation from the soil, giving farmers an advanced understanding of soil structure, allowing accurate variable-rate application mapping.

How the largest of the large farms look at technology

Three farmers, all running more than 25,000 acres of crops, are ooking optimistically at how technology can help manage labour and financial challenges in their farms.

The three farmers, including Jason Friesen of G&B Farms and Resilire Ag Ltd. of Watson, Sask., were part of a panel at Agritechnica 2025 in Hanover, Germany.

Nick Paterson is general manager of Excel Farms in Australia, which manages about 200,000 acres with some parts of the operation 3,000 km apart on the east and west side of the country.

Paterson says low commodity prices and labour challenges are issues for him, and he’s working with equipment monitoring technology to help optimize the system.

Maxim Bozhko, CEO and owner of Sanyrak Management Company in Kazakhstan, says he’s reduced his tractor numbers by half by purchasing larger ones, which feed data to central software that can then be managed.

The company feeds most of its grain, from 89,000 acres, in its very large broiler and egg-laying operations, as Kazakhstan is landlocked and transportation costs drive down the value of crops there.

In Canada, Friesen and his brother crop 25,000 acres using John Deere Command Centre and Claas’s software to manage their fleet of equipment. It helps troubleshoot problems quickly with labour, including the temporary foreign workers who are employed on the farm.

All of the panelists expect to use more autonomy in the future in order to decrease their dependency on hard-to-find labour and increase per-acre efficiency.

Watch for more on these stories and some accompanying videos at the Agritechnica page here.