Zinc in your truck and tractor tires may someday be extracted and re-purposed as fertilizer, according to Titan Tire Reclamation, which is doing exactly that in the Fort McMurray, Alta., oilsands.

In an email interview with Paul Newton, owner of Saskatoon Wholesale Tire, the Titan dealer said waste tires have been a major environmental concern in Canada since the 1990 Hagersville, Ont., catastrophy.

“That tire fire burned 17 days, devouring 10 million scrap tires. Waste tires are a major problem around the globe. Demand for tires will not diminish. In the last five years, tire sales have increased by more than four percent per year. Globally, more than three billion tires were manufactured and sold in 2019. Every tire will some day have to be disposed of.

“I think Titan picked the oilsands as the ideal location to set up their tire processing plant because of the abundance of big tires and the close proximity to world-class expertise in optimizing oil recovery.”

The proprietary process Titan created is called thermal vacuum recovery (TVR). It harvests oils and gases from giant 10,000 pound industrial tires at the end of their life cycles.

The TVR process results in an efficient and complete separation, with the remaining char or carbon black, or CB4000, containing up to eight percent zinc.

Titan explained that they begin the reclamation with careful attention to each tire. They document the make, model, size, serial number, plus where and when the tire was made. The tire is then loaded into one of the reactors.

The reactor is initially heated by either propane or natural gas and is sealed and purged with nitrogen. As the chamber temperature rises, the tire starts to off-gas and break down.

While the tire continues to off-gas, operators run the gases through condensers behind the reactor, thus dropping the heavy oil and light oil. The light gas loops around and is burned to continue fueling reactors. Auxillary propane and natural gas are shut off.

When the process is complete, the reactor will have extracted all oil and gas from the tires, plus the steel and CB4000.

A 10,000 lb. tire will yield 600 gallons of oil, about 2,100 lb. of quality steel plus 3,200 lb. of recycled carbon black. Titan said it is getting about seven percent zinc per pound of recycled CB4000. This bodes well for their plans to blend the zinc into a commercial fertilizer.

Carbon black is made by incomplete combustion of heavy petroleum products. Some CB4000 captured by the reclamation process is recycled back into tires. However, it can only be used sparingly in certain parts of the tire. The tread, bead, sidewall and inner liner all have tight specifications that tire manufacturers must follow.

Companies working in the oilsands have been greening their operations, attempting to clean up their public images, as have fossil fuel extraction companies around the world.

Located just north of Fort McMurray, Titan’s reclamation plant was the first in the region. Since 2016, the company has processed more than 39 million lb. of tires, and has capacity to process more than 900,000 lb. per month.

When Titan started researching zinc in tires and in fertilizer, they turned to Western Ag Systems in Saskatoon.

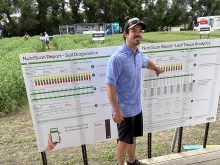

Western Ag organized CB4000 studies with multiple universities across North America. Since 2018, it have focused on the potential benefits of recaptured zinc in corn.

Canadian studies have been conducted at Enchant, Alta., Bow Island, Alta., and Leroy, Sask.

The final agronomists’ report is in peer review and is expected to be released this summer.

Titan said when the test results are released, it will determine the true value of the product to the producers. At that point, Titan said it may partner with a fertilizer distributor.

Although the process isn’t ready yet to enhance the micronutrient balance in your fields, research agronomists have confirmed that zinc contained in CB4000 is bioavailable.

There’s a significant increase in zinc uptake from CB4000 amended soils. Re-purposing zinc into fertilizer can be viable.

Zinc is the fifth most important human nutrient deficiency according to the United Nations World Health Organization. Within the broad acre field crops of North America, zinc deficiency in corn, barley and wheat are common on soils with high pH, low organic matter and high carbonate. This limit in zinc supply is often exacerbated by increased plant demand under high-yielding hybrids and new semi-dwarf genetics.

Titan said the 900,000 lb. of tires processed per month at its Fort McMurry reactors is the minimum amount required to set up a new plant, which limits the potential for many plants to be established across the Prairies. The process can use virtually any kind of rubber tire, including trucks, scooters, bicycles even golf cart tires. The all have the same basic chemistry and they all contain zinc.

Editor’s note: Later this summer when the research becomes available, The Western Producer will publish findings of multiple agronomic studies into rubber recovery zinc in corn crops.