If stainless steel lasts five times longer but costs the same as mild steel, then … what was the question again?

If you bought high-quality 304 stainless steel aftermarket components to replace worn carbon steel parts in your JD drill, you’d expect to pay more, right? Wrong, according to Romafa.

“Many of our stainless steel replacement parts cost the same as OEM steel parts directly from John Deere or the other manufacturers” says Romafa representative Jim Kinnaman in a phone interview.

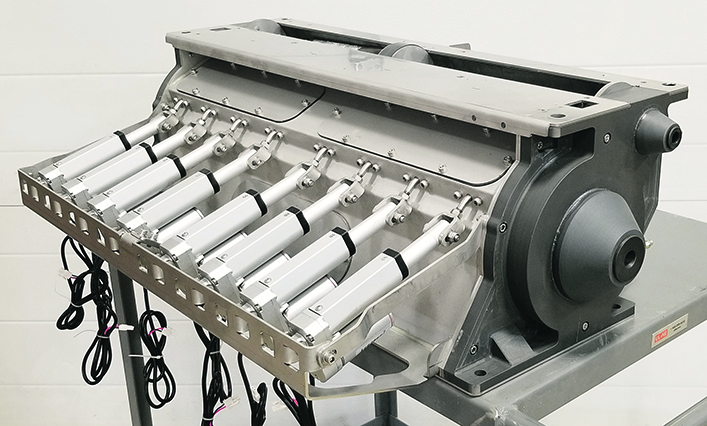

Romafa Metal Works, located near Arborg, Man., launched in 2012. The company specializes in designing and manufacturing replacement components for air delivery systems, using stainless steel.

“A 304 stainless steel has a much higher nickel content. That’s why a replacement component has about five times the lifespan compared to the original carbon steel. The big advantage is that a lot of our prices are very similar to what John Deere would charge. We’re price competitive on parts from Flexi-Coil, CaseIH, New Holland and Morris.

Kinnaman says that, depending on the fertilizer going through the seeding equipment, some of those OEM parts are ready for replacement after just a couple years. He says that if you want to make those original parts last, you’ve got to clean out every bit of fertilizer before storage. That fertilizer mixes with condensation and just eats into the metal.”

Although all replacement parts from Romafa are a straight swap out with the original component, some re-engineering has been done on the function and performance of the new part, even those designed for much older carts. Where there were little glitches in the OEM part, they are gone from the Romafa replacement.

On meter housings for example, the design of a new part maintains all the functions of the original, including OEM hopper cleanout. However, a smoother internal construction design and fabrication makes clean out easier. Welds are pacified, or pickled, to retain stainless corrosion resistance. An example of component enhancement is the improved meter seal that eliminates back pressure.

Kinnaman adds, “We have PVC connecting with our stainless steel with a very tight fit in our air system. On the John Deere they have corrosion that allowed air seepage. That creates a vacuum that siphons the product through. If your cart was sitting still and not seeding, and your fan was running, it would suck seed through and spit it on the ground even though your meter wasn’t metering.

“If you’re seeding canola and it’s running out on the yard, that an expensive mistake. That’s a small, small seed. It siphons through very easily. We’ve added a seal that prevents this siphoning.

“The original John Deere part had a plastic disconnect, which does not work for very long. Just the fact that we replace that plastic with stainless steel, makes it easier for the farmer to switch off one side or the other when that’s what he wants to do.”

The company name Romafa comes from using the first two letters of Ronald and his wife name Marcela plus family.