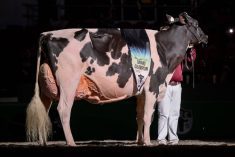

Garth Hockley couldn’t help himself as he stood next to a robotic milking machine inside his barn: he had to grin as he admired the technology.

“I never get tired of watching it,” said Hockley, who opened up his dairy farm to visitors for the National Holstein Convention held in Brandon last month.

Hockley, who milks 60 cows with his wife, Elaine, son, Neale, and daughter-in-law, Dayna, installed a robotic milker on his farm near Brandon in December 2010.

The Hockleys also built a new free stall barn on their farm to accommodate the voluntary milking system, where Holsteins walk into the robot stall when they’re ready to milk.

Read Also

Breaking down successful winter feeding into six steps

It’s that time of year when it is important to start planning for a cow herd’s winter feeding program. Here are six steps I think are necessary to consider when getting your feed tested.

Robots cost $225,000 to $300,000 and a new barn is sometimes necessary, which means it would seem logical that larger dairies with herds of 300 or more cows would be a better fit for a voluntary milking system because of higher revenues.

However, calculations from Ontario and anecdotal evidence on the Prairies indicate robotic milking is best suited for farms with 60 to 240 cows.

Blaine McLeod, chair of the Saskatchewan Milk Control Board, runs a dairy with 300 cows near Caronport, Sask. He expanded his farm by 100 cows about a year ago, but decided to continue running a milk parlour rather than install robots.

“(There are) efficiencies that come from size. It just means running the parlour a tiny bit longer,” McLeod said.

“I’m milking 100 more cows than I was a year ago. My labour requirement to do that hasn’t increased substantially. We’re talking two to three hours (of additional labour).”

Research in Ontario and other regions backs McLeod’s argument that smaller and mid-sized operators benefit more from robotic milking than large dairies.

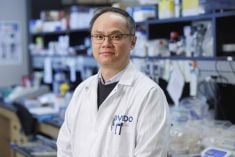

The tipping point is in the range of 240 cows, said Brian Lang, dairy specialist with Ontario’s agriculture ministry in Woodstock.

Robots can handle about 60 cows. As a result, producers needing more than four robots are probably better off with a milking parlour because of the high capital cost of installing robots and the inherent efficiencies of large parlour operations. The availability and cost of employees is a key factor in the calculation.

“If labour is relatively inexpensive and very reliable, that moves the equation more to the parlour side,” Lang said. “If labour is expensive … or you plain just can’t get it, then (the balance) goes to the robot side.”

McLeod said producers in Saskatchewan who are converting their barns to robotic milking tend to be smaller operators or producers who are struggling to attract and retain labourers.

In his case, two sons work in the family business and his farm is close to Briercrest College, which offers a pool of part-time labour.

McLeod based his decision on economic returns, but other dairy farmers, both large and small, may be swayed by a shortage of employees willing to work in milk parlours.

Some Hutterite colonies in Saskatchewan have switched over to robotic milking, he added.

“You wouldn’t expect that colonies would have a labour shortage, but what they’re finding is that they’re having difficulty keeping their young people connected to the farms.”

Labour was a factor in Hockley’s decision to install a robot.

“The hangup in every case was the milking process. You can get young folks to do chores, but we’re pretty fussy about how we milk our cows and I think we should be,” he said.

- Manitoba has approximately 60 farms with milking robots, representing 18 percent of the 334 dairy farms in the province

- In Saskatchewan, 10 to 15 percent of dairy farms use robotic milking

- In Ontario, a new milking robot is installed at a farm every seven to 10 days. However, with more than 4,000 dairy farms, it will take years for robots to replace milking parlours in the province

- A milking robot costs $200,000 to $300,000, depending on who is asked and how many are bought

- Lely, a milking robot manufacturer, has sold more than 12,500 robots worldwide. The company, based in the Netherlands, opened a manufacturing plant in Iowa this March to satisfy North American demand

“This robot is consistent… It’s never late for work, it’s never hung over.”

However, Hockley disagreed with the assertion that robots are best suited for smaller dairies.

He said a producer in Elm Creek, Man., has 12 robots and another in La Broquerie, Man., has eight, which shows that robots also offer efficiencies for large dairies.

Jack Rodenburg, a robotic milking consultant in Ontario, has written that robots are less competitive than parlors for larger herds. However, the scale will tip toward voluntary milking as labour costs increase and robot prices fall.

McLeod pays his workers an hourly rate in the mid to high teens, but speculated that the shortage of workers may force some dairy farmers in Saskatchewan to pay $20 per hour.

“I wouldn’t think that would be the standard … but it’s not out of the question,” he said.

“You’re competing with really large farms, on the grain side. They are setting the standard (for wages).”

Some farmers also dislike managing employees, which might encourage the move to a robot, Lang said.

Employee headaches were an issue for Hockley, but another factor was quality of life.

Decades of handling milking equipment and cattle can be hard on knees, hips and other joints. That kind of work isn’t as easy as it once was for Hockley and Elaine, who are now senior citizens.

“This (the robot) has certainly changed our lifestyle. We’re still putting in time (in the barn), but it’s not so labour intensive.”