Big slurry tankers Top out at more than 100,000 pounds so there’s no room for slop in the steering and suspension

GUELPH, Ont. — The tanker industry concedes it has maxed out size-wise with its latest generation of big slurry carts, so now it’s time to make effluent more efficient.

One of the best ways to quantify tanker efficiency is to count the number of round trips or the number of gallons moved per shift. If tankers have hit their maximum size, then the next logical step in their evolution is to make them cycle faster.

Industry reps talk about better brakes, better suspension and better steering when they discuss shorter cycle time and higher transit speed.

Read Also

Powdery mildew can be combine fire risk

Dust from powdery mildew can cause fires in combines.

Those factors are driving their engineering departments to design safer tankers.

They also wrestle with compaction, says Dave Rose of Jamesway Farm Equipment.

Jamesway, one of the leading manufacturers of manure handling equipment in Eastern Canada, has products for every type of manure management situation.

“Once you’re in the field, compaction is the biggest issue farmers have with moving liquid manure by tanker cart,” said Rose.

The fully loaded Jamesway Ultra-Trac four-axle tanker has a 23 pound per sq. inch footprint on the soil, he added

Rubber tracks have received a lot of attention recently as a way to alleviate soil compaction, but Rose doubted they would work on a slurry tanker.

“For one thing, once you’re at this size, you need all four axles to be steerable. How could you do that with tracks,” he said.

“With eight tire steering, we don’t get any smearing or ridging in the headlands.”

In the field, the Jamesway trailer works the same as other big four-axle units. In a left hand turn, the front tires steer left, into the corner. The rear tires steer out, to the right, to bring the tail end around.

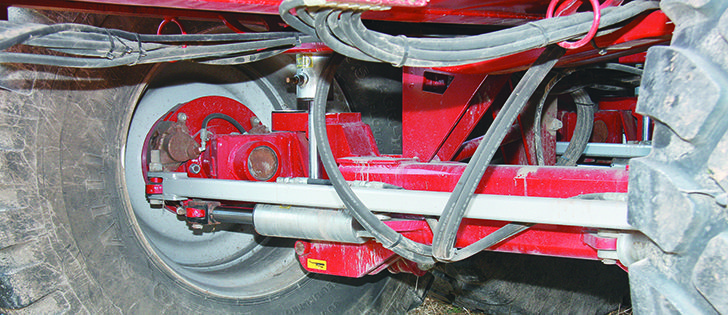

Steering input on the Jamesway tanker is independent of the tractor driver. Once the trailer is hooked up, it steers itself with two large tire rods pivoting left and right on a steering plate on the hitch.

If the tractor turns left, the left tie rod is pushed rearward to make all eight tires steer in the correct direction.

“We have independent hydraulic suspension on all eight wheels,” he said. “You charge the closed circuit once with the tractor. When it’s 50 percent full with oil, you close it off. Then disconnect the line from the tractor and you’re ready to go. The suspension cylinders on each side of the trailer are linked. If you have to cross a ditch at an angle, the suspension walks itself through.

One wheel at a time drops down into the low spot while the other three wheels go up. The four wheels compensate for each other. The same thing is happening on the other side at the same time. There’s no accumulator. Just two independent circuits. Each wheel has 15 inches of vertical travel.”

The system also lifts the front two trailer tires during empty transit and transfers weight front to rear to put the optimal load on the tractor.

The brakes are hydraulic, running off the tractor’s auxiliary braking port. The trailer brakes are activated when the operator hits the tractor brakes and are powered by the tractor’s hydraulic system for maximum stopping power.

The brake pad surface is 550 percent larger than the industry standard, and the disc surface is 65 percent larger.

“One other technical feature we have is a full frame,” Rose said.

“Our engineers say that using the tank itself as the frame will weaken the tank. So we build an independent frame and then bolt the tank on top of it.”

Pascal LeClerc, global sales director for Teamco, which manufactures high-end tanks in Quebec, said it becomes clear once tanks have reached four axles and 9,500 U.S. gallons that new efficiency will have to come from building a better tanker rather than a bigger one.

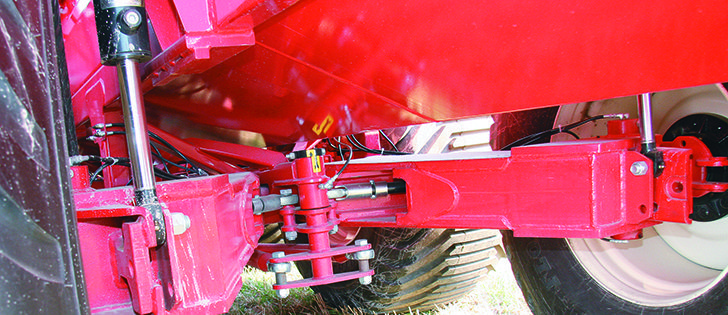

He said features on his company’s machines include a closed-circuit hydraulic steering system that eliminates most of the mechanical components that cause bad handling.

“This is a unique hydraulic steering system that makes our trailer very safe. You align it only once a year. It stays in alignment better than those mechanical systems with the big metal rods and ball joints,” he said.

“We have a single hydraulic cylinder that moves oil back and forth to the steering cylinders on the four axles. It won’t wobble going down the road and it adjusts itself automatically if necessary. It handles very well compared to the steering and suspension on other tankers.”

LeClerc said the tanker also has independent, hydraulically controlled suspension for all eight tires.

Each wheel has a 16 inch stroke, which not only provides a smoother ride but also helps the tractor driver keep control on rough roads because the tires stay in contact with the surface instead of bouncing up and down.

He said the hydraulic suspension lets the operator manipulate the fore/aft weight of the tanker for an optimal weight on the tractor hitch.

When running back to the lagoon empty, the operator lifts the front pair of tires off the ground to allow faster speed.

For more information, contact Rose at 905-701-9687 or visit www.jameswayfarmeq.com or contact LeClerc at 819-350-2634 or visit www.teamco.ca.