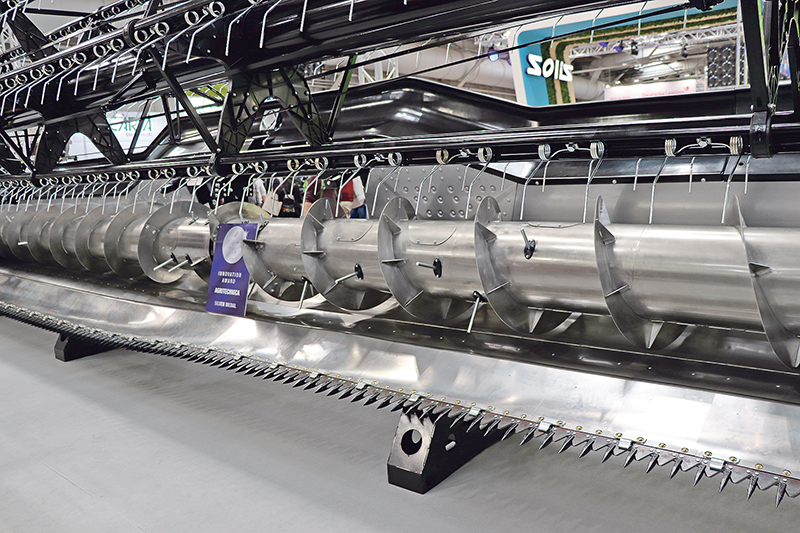

Hannover, Germany — The Biso 3D Varioflex header offers a unique solution for growers who want a durable flex head that can switch between multiple crop types with little set-up time.

Operators can change from cereals to canola in a few minutes by removing the crop dividers, setting the cutting bar as far forward as it can go, and hydraulically fold out the side knives into canola position.

The company was awarded a silver medal for the header in Agritechnica’s innovation awards.

“The technological feature on the Biso header is this parallelogram, which is helping us keep our fingers at the same angle; it’s 10 degrees,” said Vaclav Stursa, general manager of Biso.

Read Also

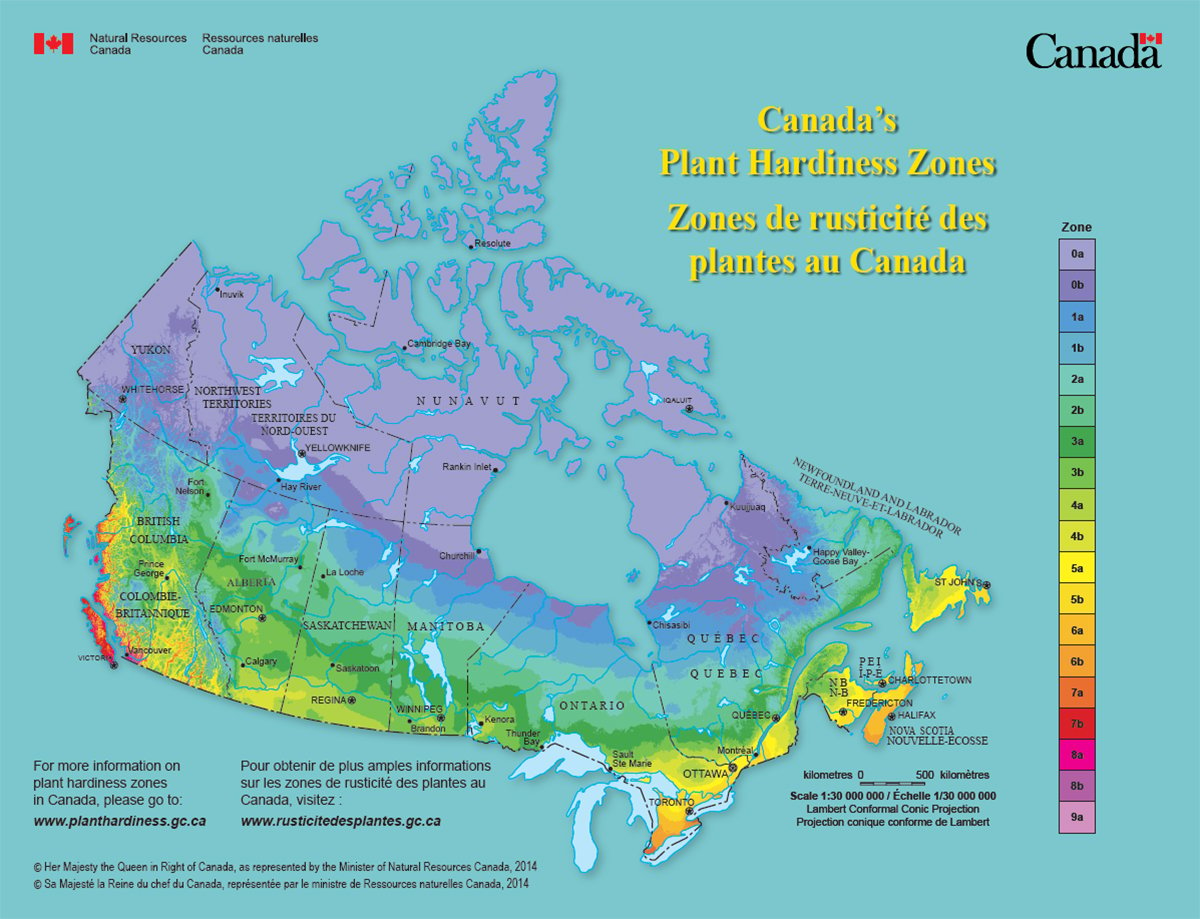

Canada’s plant hardiness zones receive update

The latest update to Canada’s plant hardiness zones and plant hardiness maps was released this summer.

The parallelogram-controlled flex cutter bar on the 3D Varioflex header prevents the knife from twisting even with up to 6.75 inches of travel between each support arm.

The header’s Vario system controls the distance between cutting bar and the auger.

The cutting knife can be as close as seven inches to the auger, and it can be pushed out as far as 38.5 inches from the auger, giving the flex floor 31.5 inches of travel.

There are no belts that move crop on the header; instead, the material on the stainless steel floor is taken to the combine intake by the auger.

Stursa said this simple and low-maintenance system is an important feature of the header.

The header has air suspension for each knife support arm powered by an integrated air compressor.

If the header is equipped with the “i” option the cutting bar’s flex is electronically controlled with air bellows and pneumatic valves that adjust the knife support bars to the height, based on the pre-selected ground pressure value.

There is a plastic side plate behind the cutting bar under the header, and under this plate sits a pressure sensor that controls the cutting bar’s vertical movement.

“Which is giving us the possibility to adjust the pressure on the ground from two kilos, up to 50 kilograms,” said Stursa.

The header uses spring metal for the pick-up reel tines, which means the company had to figure out how to avoid a wreck when the reel gets too close to the cutting bar.

To prevent the reel tines from getting caught by the knife, the “i” models are equipped with an intelligent collision control, which allows operators to sneak the reel in tight to the cutting bar without hitting it.

“So if it will touch the knife, the reel will automatically go up,” said Stursa.

“On these arms we have a potentiometer, which will immediately send a signal that one arm is going up and the reel must go up.”

The smallest header in the Biso 3D header range is 22 feet wide, while the largest header is 60 feet.

The header is wirelessly controlled by a 13-inch tablet, which can be installed on any type of combine.

If an operator comes to crop patches that aren’t ready to combine, they can open up the cut-out on the right-hand side of the header and push the crop into a swath to be harvested later.