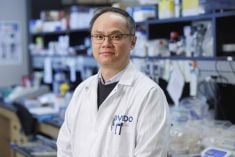

CAMROSE, Alta. — Driving down the highway with veterinarian Dr. Frank Marshall is like receiving an agricultural history lesson.

On the left side of the road he points out an old dairy barn that has not seen cows in years. On the right side of the highway is a typical 50-sow barn that once dotted the Prairies. None of the barns have seen animals in years.

When Marshall graduated from the Western College of Veterinary Medicine in 1983, the pig Industry was seemingly a license for swine farmers to print money, he said.

Read Also

VIDEO: Bittersweet harvest for this family farmhand

Bruce Burnett helps his brother harvest wheat and canola for the last time on the family farm in Manitoba where they both grew up.

“I thought this was an amazing business. At that time, it had cost about $40 to raise a pig, but you got $200 in return.”

The returns are not the same now.

After joining the Camrose Veterinary Group, swine became Marshall’s specialty in between the clinic’s rotations of looking after everything from iguanas to bison.

Later, when Marshall set up his own practice specializing in swine, he travelled about 160,000 kilometres a year to offer veterinary services to the thousands of hog producers across the Canadian Prairies and into Montana.

It wasn’t uncommon to have more than 350 Alberta producers attend regional meetings for the latest information on health, markets and opportunities.

Companies were building hog barns across the Prairies.

Dr. Ed Doornenbal told Marshall there were about 300 hog farmers just in the area near the small communities of Barrhead and Neerlandia. Now, there are four in the same area.

At last count, about 260 commercial hog producers are left in all of Alberta and another 500 farms with smaller herds.

A combination of retiring producers, disease, government programs and the wildly cyclical markets for hogs forced all but a very determined handful of producers out of the business.

“What is left of our clients are our top-notch producers,” Marshall said while on his way to the 700-sow Hartland Colony barn for the quarterly veterinary herd health checks.

“This is one of the best barns you will ever see,” said Marshall as he pulled into the colony near Bashaw, Alta.

John Waldner, Hartland’s pig barn manager, said he had never worked in a hog barn before the colony was created with a split from the Pleasant View Colony in 2008.

The former mechanic and welder said caring for pigs has been one of the most fulfilling jobs he has had, ensuring a barn full of healthy and contented pigs and happy workers.

Each morning, the crew, including Waldner, his brother, Martin Sr., the hog barn’s senior manager, and the rest of the staff gather in the office to discuss the day and the week’s plans.

The barn flow operates like a pipeline with pigs moving steadily through the different stages of the barn each week. Any break in the pipeline’s flow from disease, breeding or farrowing can impact the pipeline through to processing.

“We have to manage the flow,” said Waldner.

Keeping the herd healthy is the barn crew’s job with recommendations from Marshall, their veterinarian.

As Marshall walks through the barn, his eyes scan the pens to look and listen for healthy animals and the ones that are off.

At one farrowing pen, he noticed a distinctly whiter piglet in the litter, an obvious sign the piglet had missed its iron injection.

Marshall takes the opportunity to share with staff the latest research on the importance of two doses of iron injections in the fast-growing piglets.

Because the barn is a multiplication facility, the piglets are checked to ensure the females have at least 14 working teats, all weigh more than 1.5 kilograms at birth and are ideal weights at each stage of production.

The fitness checks are repeated two more times to ensure only the best animals go into the barn’s in-house Landrace herd or a second program that produces high-quality Landrace and Yorkshire cross F1 replacement gilts for sale to other barns.

“To have the knowledge of Frank Marshall and where he has been in the industry and seen so many health challenges has been so important for us,” said Waldner.

“When there are any issues creeping in, we have Frank’s eyes.”

Waldner said the operation benefits from both Marshall’s expertise and the staff’s commitment to animal care.

“It’s a group effort. This is the best part of working with animals. It is very rewarding and you get to teach about caring about animals.”

The colony has worked with Marshall since 2008, when its barn was constructed, even taking training courses in Marshall’s Camrose office.

Marshall is one of the last remaining pork veterinarians and one of the last remaining independent veterinarians in the province.

Before Marshall leaves the barn, he looks at the colony’s extensive record-keeping system, which keeps track of weaning dates, farrowing rates, feed consumption and a myriad of other reports. Just like walking through the barn, the reports give a snapshot of the management in the barn. What he sees in the reports is a well-run barn.

“The reports give you a finger on the pulse of the barn. If you can’t measure it, you can’t monitor it,” said Waldner, who added they spend about two hours a week putting data into the computer.

As Marshall leaves the farm, the work doesn’t end.

Driving to and from his Camrose office, Marshall takes a steady stream of calls from producers wanting to know about drug protocol or particle size of feed that the caller believes is causing gut issues in the hogs.

After 42 years as a veterinarian, 35 as a specialized hog veterinarian, the answers come quickly.

Marshall has seen many new diseases emerge in those 42 years. Some of those disease outbreaks put producers out of business. Marshall and his colleagues helped develop protocols for disease eradication and protocols to keep remaining pigs healthy.

In the beginning, the Alberta government developed the Alberta Swine Herd Health program, which paid veterinarians to travel to farms to show the value of veterinarians and have a comfort level. Because of those programs, some diseases are no longer seen.

The wild financial swings brought about an industry correction in 2006-07, when half the producers in Alberta disappeared, representing 38 per cent of production in Alberta.

At the same time, the industry saw the development of health and management tools that showed the value of disease prevention protocols.

With a large swine client base disappearing, it was a natural fit to add poultry production medicine into Marshall’s practice. He has looked after poultry, in addition to hogs, for 19 years.

In the last two years, 10,000 sows have left the industry from his client base.

One of Marshall’s worries is the number of backyard pig producers who don’t follow the strict health protocols required in commercial barns. He worries an emerging disease may be brought to the commercial sector through backyard production.

“Our industry has all the checks and balances that are in place that really help drive the production of safe pork.”