Every two years, the German farmer organization DLG awards prizes to some of the best ideas in agriculture at its giant farm show in Hanover, Germany.

With more than a half million attendees, Agritechnica is the largest event in international agriculture. Owned by DLG, the show attracts companies from around the globe to market their technology to producers.

The awards are based on technology that has come to market in the past two years and judged by an expert panel of engineers and agricultural consultants.

This year, Krone won for its new mobile forage pelleting machine. Like a round baler, the machine picks swaths, from cereal straw to alfalfa, and converts them into 16 millimetre wide pellets.

The company designed the machine to produce pellets for both livestock feeding and energy production.

About the size of a large baler, the unit has windrow pickers similar to balers. It feeds the crop to a conveyor belt, which carries it to a pair of press rollers, each 80 centimetres wide and 80 cm in diameter.

The rollers have alternating teeth and perforations, which create the pellet forms. The pellets fall through to the centre of the rollers, where flighting carries them to a second conveyor, which loads them into the hopper.

Read Also

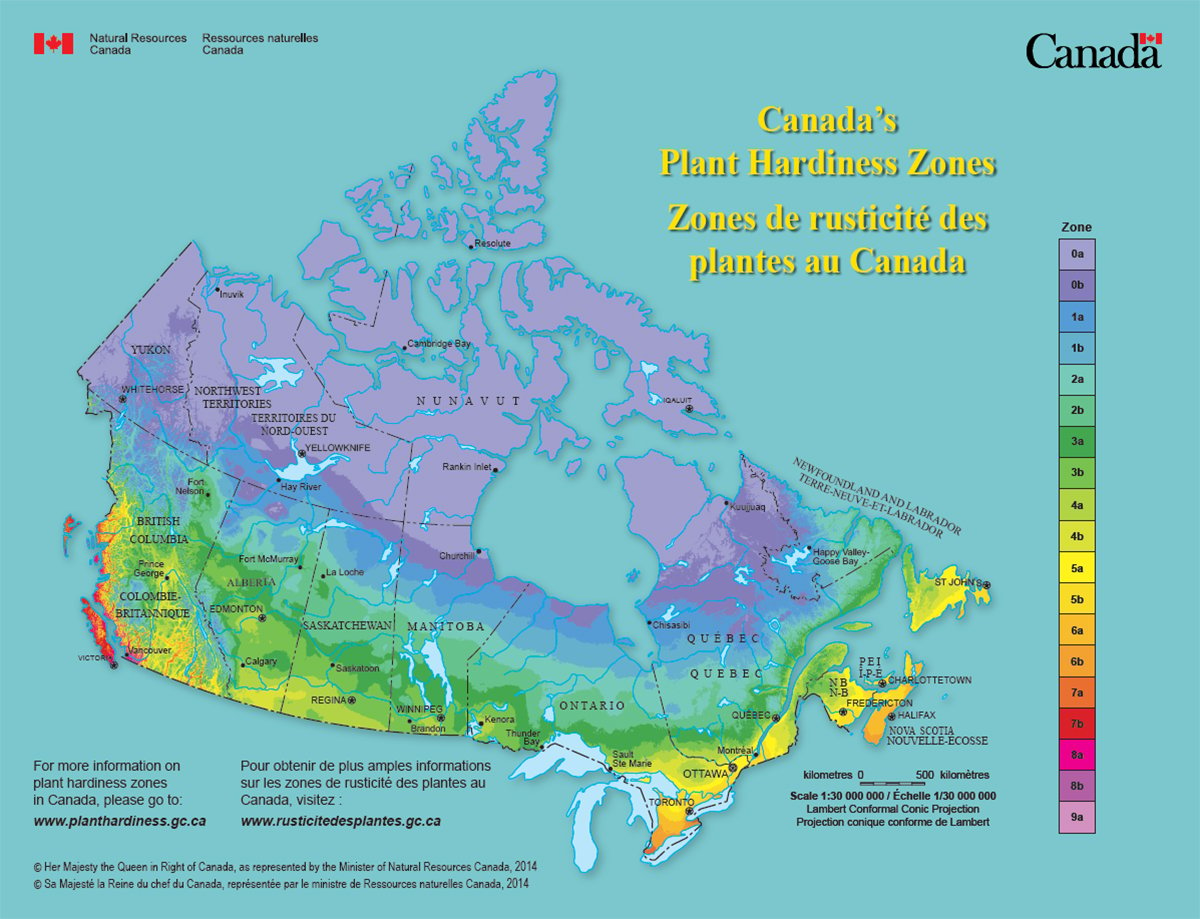

Canada’s plant hardiness zones receive update

The latest update to Canada’s plant hardiness zones and plant hardiness maps was released this summer.

The pellets can be handled with conveyors or augers and have a density three or four times that of straw bales. They are compressed to 600 to 700 kilograms per cubic metre, and their heating value is equal to about 2.5 to one when compared to diesel heating oil.

The ability to harvest pellets as feed allows producers to create a measurable, storable form from straw or hay without further processing in the yard.

The machines can be set to run as stationary pelletizer with an optional bale shedder attachment if hay or straw bales are available.

The company says the pellets are also used as bedding for cattle and in some hog operations.

John Deere won a gold medal for its Pro Cut system, which monitors and adjusts the spacing between the knives and the shear bar of a forage harvester’s cutting drum while the machine is running.

Sensors incorporated in the shear bar continuously measure the spacing between it and the knives and monitor the sharpness of the knives. The system makes recommendations to the operator as to when the knives should be sharpened for optimal efficiency and cut quality.

A Canadian company was recognized for its all-mechanical continuously variable transmission design.

CVT Corp. from Sainte-Julie, Que., has been designing and building continuously variable transmission units for industrial use in power generation and fan drives for more than a dozen years. However, it has just made a move into building them for agricultural applications.

A tractor transmission is one of its current products, but DLG awarded a prize for the company’s partnership with front power take-off and hitch company Duisburg.

CVT Corp. built a variable speed p.t.o. transmission that fits be-tween the front output from a tractor and a front mounted implement. It allows the operator to run the tractor at variable r.p.m. while maintaining a constant p.t.o. speed. This in turn allows producers to gear up and throttle back, saving fuel.

The company said it has plans for rear mounted and other CVT applications for its all mechanical CVT.

The technology avoids relying on a combination of hydrostatic and mechanical transmissions as most CVT designs do.

Instead, it uses the toroidal CVT design, which is cheaper to produce and highly durable while avoiding parasitic heat losses from hydraulic processes.

For a complete list of Agritechnica award winners, visit this story on producer.com and look for Western Producer coverage from the Nov-ember event in coming editions.