Small grains header designed to be compatible with WD5 Series is expected to be attractive pairing for prairie growers

In mid-July, Case IH announced HoneyBee WSC draper headers will be compatible with the brand’s recently redesigned WD5 line of windrowers. The company announced that pairing at the Ag in Motion farm show near Langham, Sask.

Choosing to announce that collaboration at a western Canadian farm show made sense because HoneyBee products are manufactured in Frontier, Sask., in the heart of its home market where demand for draper headers is high.

As well, pairing a draper header designed for small grains along with the WD5’s high road speed should increase their appeal to prairie growers, said Brian Spencer, Case IH’s hay and forage marketing manager.

“This is the first public unveiling of our new draper collaboration with Honeybee to fit our WD5 Series windrower,” he said in an interview at AIM. “(The WD5) is the fastest in the industry for on-road speed, which is great for Canada, because you have a lot of roading from farm to field or field to field. Our standard speed is 22 mph (35 km-h). But we have the high-speed option of 30 mph (50 km-h).”

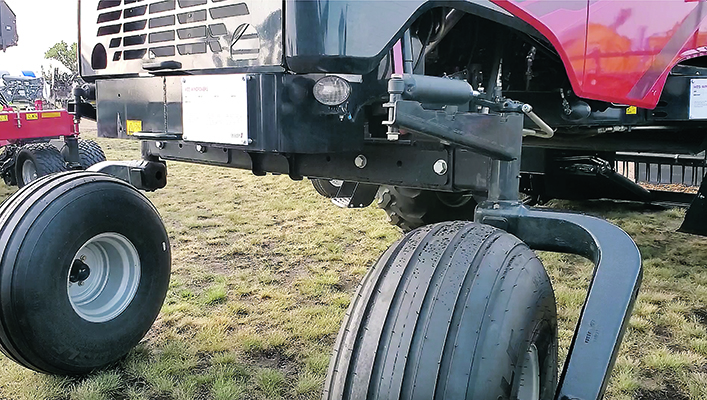

The WSC HoneyBee draper header offering compatibility with the WD5s is available in 30- and 36-foot widths. Aside from the standard centre windrow delivery design, they allow for double swathing with either a left- or right-side discharge. They use HoneyBee’s SCH cutter bar system and have adjustable guide wheels to help prevent gouging.

This year is the second full season of production for the WD5 Series machines, and Spencer said the brand is seeing strong demand. The HoneyBee pairing is expected to add to that demand.

The three-model WD5 Series is the result of a ground-up redesign that included a new powertrain. Power now comes from a 4.5 or 6.7 litre FPT diesel that delivers 150, 210 or 250 horsepower. That muscle gets routed to the drive wheels via a hydrostatic transmission.

“The machine itself, when it was redesigned, was given an all-new powertrain, front to back,” Spencer said. “And a new drive-by-wire steering system. Drive-by-wire greatly reduces the amount of operator input for straight-line tracking. With the rear steering drive-by-wire, we feel we have the best guidance system on the market.”

Upgrades on the WD5 Series also included a new rear-axle suspension and redesigned cab suspension to make things a little more comfortable for the operator, especially at higher speeds.

The WD5s come from the factory with Case IH’s AFS Connect telematics, and a five-year subscription to the service is included in the purchase price. That allows for remote viewing, so a farm manager can monitor machine operation from anywhere.