On-farm biogas systems use anaerobic digestion to recycle livestock manure and crop residue, which can create environmental and business opportunities

Rob and Rachel McKinlay say they have future-proofed their Woodstock, Ont., dairy farm.

Using a factory-built anaerobic digestor, Harcolm Farms has created a closed-loop system to supply the total electrical needs for the family’s dairy operation and household.

Through summer heat and winter cold, the system breaks down manure to produce methane-based gas used for electrical generation.

Byproducts from the digestate provide cow bedding derived from dried manure and a nutrient-rich liquid slurry to fertilize their fields.

Now in its fifth year of operation, Ontario’s only mini-biodigester is going strong and has transformed the operation’s management of dairy manure, finances and the environment.

Read Also

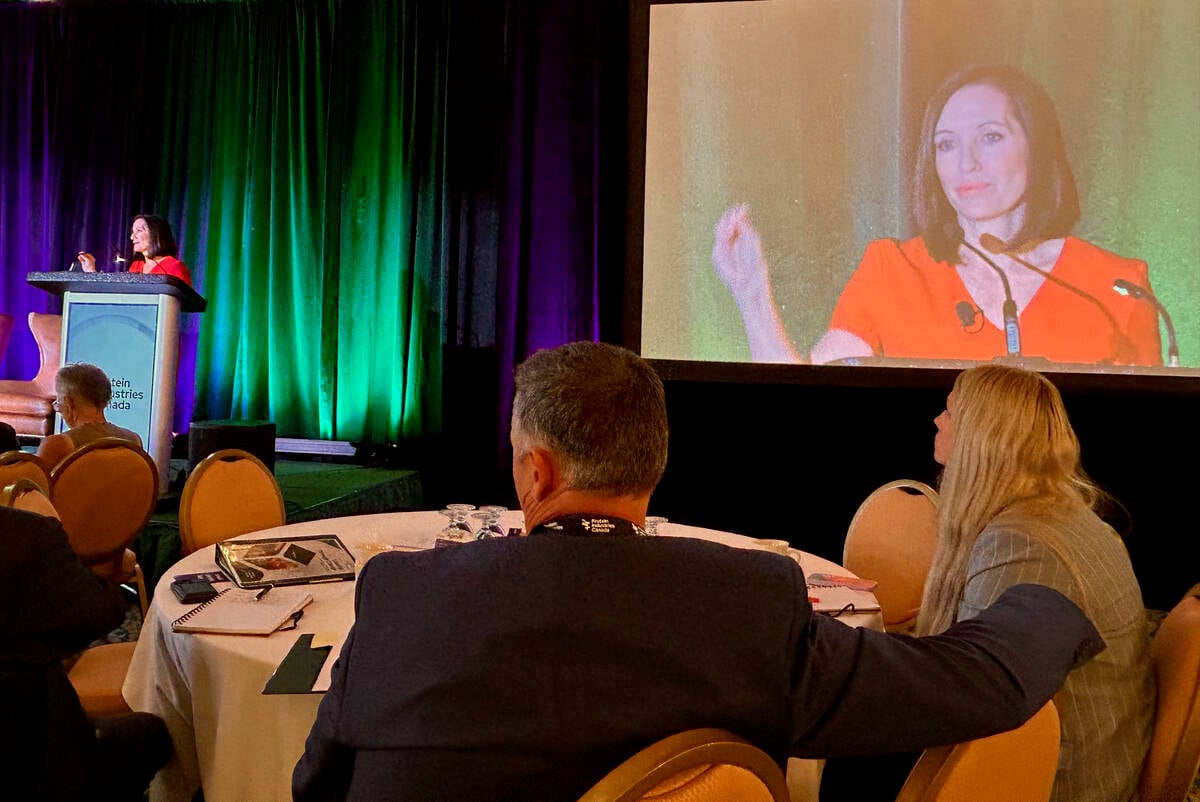

Canada told trade crisis solutions in its hands

Canadians and Canadian exporters need to accept that the old rules of trade are over, and open access to the U.S. market may also be over, says the chief financial correspondent for CTV News.

“Everything that passes through our digester is coming from the farm, primarily the dairy manure and then a bit of waste feed goes in the digester. Our motivation was about closing the loop and making the best use of the farm waste,” said Rob McKinley, also a director of the Canadian Biogas Association.

“We’re taking about 90 percent of the methane that’s available from the organics and we’re destroying (burning) them at the start of the carbon cycle. Essentially, we’re making it so that the methane is not available to the atmosphere.”

Harcolm Farms is small compared to most Ontario operations. It robotically milks about 70 cows in its freestall barn. But the mini-biodigestor has garnered a lot of interest from farmers, government and the public for its self-contained technology.

“The thing that attracts attention is the scale and opportunity for widespread adaptation across average farms,” McKinlay said.

“When we compared the energy potential of the feed stock and the energy needs on the farm, we saw an opportunity where those two could balance. We could produce enough energy on farm in the form of electricity to offset 100 percent of our electricity needs. Economically we control the cost of our inputs, in this case electricity.”

Liquid manure is pumped into the 10,000-litre anaerobic digester instead of going directly to a lagoon. After about a 30-day retention, the material is then pumped through a screw press, which separates solids and liquids.

The solids are used for bedding in the freestall barn while the remaining digestate, rich in nutrients, is used as fertilizer.

“I’ll spread about 4,000 gallons an acre as a starter fertilizer for the alfalfa and then after every cutting we put 3,500 gallons an acre on and we don’t do any commercial fertilizer on our alfalfa forages,” said McKinley.

“I’m going to see the benefit the most on my grain corn. I’m still aiming for 200 pounds of actual nitrogen, but I’m getting the advantage of multiple sources of nitrogen coming out of the digestate and likely keeping a higher percentage of the nitrogen in the soil accessible to the plant compared to someone else that’s spreading raw hog or dairy manure. They’re going to lose a fair bit to volatilization.”

McKinley said that after 30 days in the digester, the raw manure has fewer pathogens because “it’s been cooked,” which benefits the separated solids for bedding.

After much research, the farm purchased a Belgium manufactured biodigester that suited its size and electrical needs.

“It’s a 20-kilowatt system, which would probably suit someone up to 100 cows,” he said.

The system cost $400,000 with an expected payback of 10 years.

“With debt servicing and operations, we’re looking at being able to come up with about $40,000 a year offsets to service to get to that 10-year simple payback,” he said.

Jennifer Green, executive director of the Canadian Biogas Association, said there are 279 active biogas projects across Canada, comprising a variety of configurations and sizes producing electricity and heat as well as renewable natural gas.

There are 45 farms and agri-food businesses successfully capturing biogas with agricultural inputs and turning it into a clean energy source.

Municipal wastewater treatment facilities and landfills comprise the bulk of anaerobic digestion facilities or biogas capture using a series of wells and pipes.

Over half are in Ontario, with Quebec and British Columbia making up another 25 percent. Alberta has six percent while Saskatchewan and Manitoba each have two percent.

According to a recent market report from the Canadian Biogas Association, the country’s biogas production has grown exponentially over the past 10 years but most of the potential remains untapped.

A study that calculated regional feedstock availability for renewable natural gas identified that 155 Petajoules (a measurement of thermal energy) of biogas energy from renewable natural gas is realistically available, which could provide the equivalent electrical output from 100 large hydro dams.

It suggests that Canada is tapping about 13 percent of its biogas energy potential and can bring more than eight times more biogas energy online.

By far the biggest growth opportunity is in the agricultural sector, where crop residue and animal manure make up two-thirds of Canada’s easily available biogas resources.

“As a prairie farmer in any commodity, I think biogas provides a complementary piece to what they do day-to-day,” said Green.

“It doesn’t have to get complicated. It can be as simple as the materials that they have available to them being further processed. Those materials could be crop inputs, could be crop residues, could be livestock manure,” she said.

“Outputs (are) byproducts that can be monetized for the farm at a time when agriculture is evolving in so many different ways. And to be able to use those outputs by capturing the methane, by creating an energy component and value-rich, nutrient-rich byproducts that they can utilize on the farm — there’s so many pieces that make great sense.”

Several hurdles exist for realizing the full potential of biogas energy in Canada, said Green. High capital costs are the key barrier.

Previous funding programs, particularly at the provincial level, resulted in incremental growth over the last decade. In the absence of long-term program funding, development of agricultural biogas projects has slowed.

“The showstopper in most cases will be whether or not there is supportive policy in Saskatchewan that looks to monetize the energy output, whether that is identifying it in a net metering configuration or some kind of energy program,” Green said.

“Without that, it’s very hard to pencil out these projects and that’s why we’re not seeing a lot of the projects develop across the country.”

On-farm biogas systems are a proven and cost-effective tool for Canadian farmers to secure renewable energy, cut costs, increase farm revenues and reduce greenhouse gas emissions.

There are 45 on-farm systems across Canada. Studies confirm there is immediate opportunity for hundreds more.

“Agriculture is faced with the challenge of fulfilling sustainability criteria, climate goals and methane reduction targets. Anaerobic digestion is a proven technology that is ready to scale. It is adaptable to any size of farm, accommodates a variety of commodity types and supports the growth of sustainable agriculture,” she said.

“Talking about future proofing agriculture from the perspective of upholding the livelihood of the farm and looking at the environmental sustainability of the farm, biogas really fits a sweet spot.”

More information is available at FarmingBiogas.ca.