For Norenda Farms near Gerald, Sask., and Dallas Norek, an owner-operator of the farm, GrainX Management Services has been a game changer.

The operation farms 40,000 acres, typically seeding a 50-50 split of canola and wheat. It was a test farm for GrainX and has been using it since the company started in 2016.

Norek has tried different grain monitoring tech over the years, and GrainX Command has been its most recent evolution.

Read Also

Farm groups ask feds for export sales reporting

The Agricultural Producers Association of Saskatchewan and SaskCrops asks the federal government to create an Export Sales Reporting program.

“We started switching to GrainX for the user friendliness and for the kind of home-grown, homemade parts, if you will,” he said.

“There was also not only the temperature but the moisture cables that were introduced.”

GrainX is a wireless grain storage monitoring service and technology company with three diverse levels of monitoring options: Connect, Protect and Command.

Connect is the most basic, with a Bluetooth device that plugs into the cable sensors to read temperatures and project the readings to the smartphone app.

Protect includes real-time monitoring through a modem, which receives information from the transmitting devices on the other bins. These connect with and receive feedback from the fan controllers, weather stations, temperature and temperature-moisture cables within the bin.

This data is sent to the cloud for producers to access via computer and smartphone.

The system also sends alerts via text and email if there is a notable change in quality, temperature or moisture, and a call is made to the customer if immediate action is needed.

Command is the most advanced level and builds on Protect, with an interactive artificial intelligence unit to customize aeration strategies and maximize grain quality. However, it’s not only AI. There is also a team of GrainX staff monitoring the grain and adjusting for aeration, drying and moisture loss prevention.

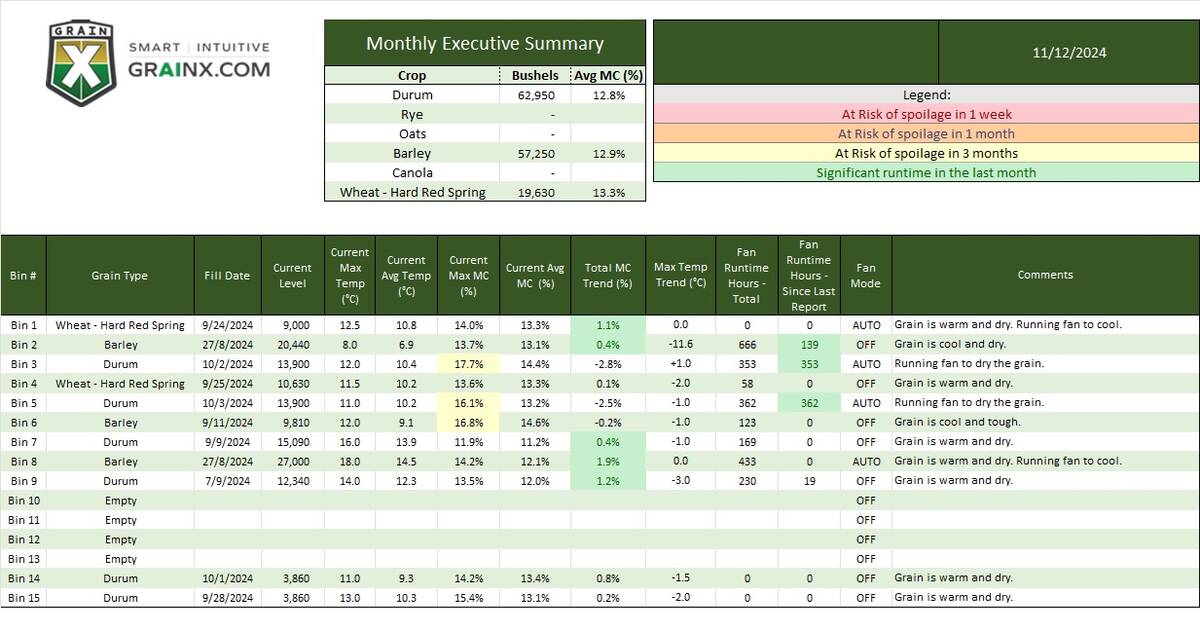

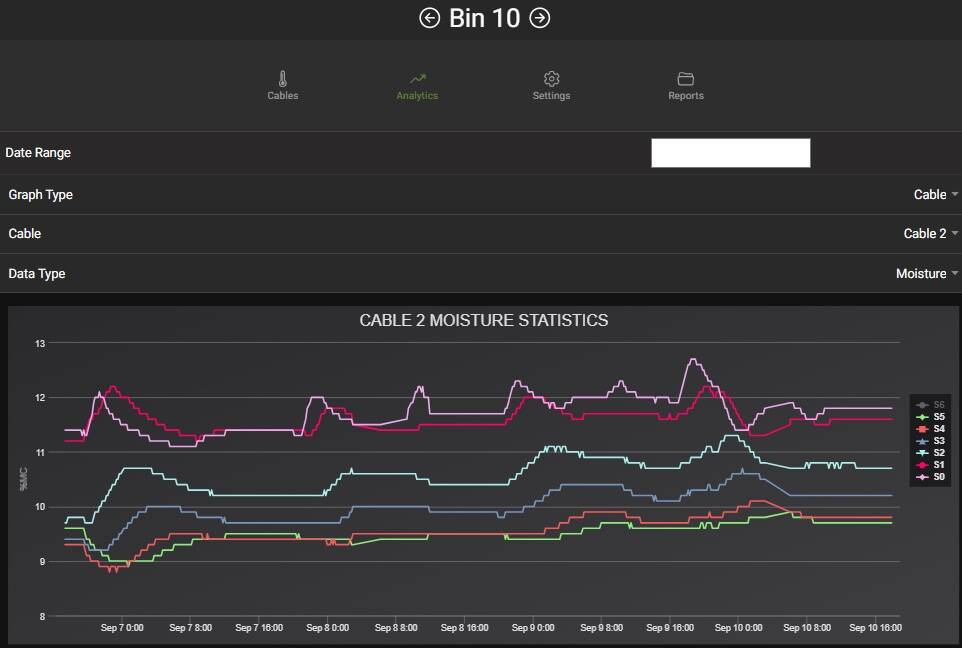

With Command, customers receive reports on grain condition, temperature and moisture changes. The reports includegraphs and charts to show temperature highs and lows and spoilage status and additional comments, such as if a cable is out of place or if the fan has recently run.

Bin spoilage status will show as red, orange, yellow or green. Red means issues should be addressed within the day, and green indicates all is well.

Most of this can also be viewed on the app or a computer, but reports are more detailed.

“It lets you worry about harvesting and not the grain,” said Calvin Boisjoli, GrainX chief executive officer.

“And there’s a set of eyes on every single sensor and every single bin at least once a week. So, it’s not just the algorithms and AI looking at the grain. It’s actually human interaction because AI makes mistakes.”

Boisjoli started the company with a desire to simplify grain monitoring for farmers and improve user experience. The other technologies and systems he’d encountered in his career were often complicated, and he noticed that many producers weren’t using them properly. It meant producers weren’t getting the most benefit from the tech they were paying for.

After testing the idea as a grain conditioning management program with Wall Grain, a partner company, he went to work on the circuit boards and software to start GrainX.

GrainX manages the set-up for all system pieces.

The company will retrofit bins to meet system needs, adding all the necessary tech alongside current cables and fans. However, bins that are to be retrofitted must be empty due to additional cables and sensors.

“In a 48-foot diameter bin, (it) would have six cables,” Boisjoli said.

“The centre cable would be a temperature-moisture and one of the radius cables will be temperature-moisture, then the balance would be temperature only. So, you’re just trying to cost-benefit balance it out so that it doesn’t get quite as expensive.”

Wall Grain’s bins are already outfitted with the necessary amount of moisture cables. This eases the installation, and it can also occur when the bins are full.

As well, the installation team figures out connectivity with the option to use the cellular network or hardwired internet. If the cellular connection is weak, the modem could be in the house with an ethernet cable running or a wireless connection with a strong antenna.

The company has worked with producers with bin yards far from the house or in an area with no cell connection, sometimes using directional antennas or third-party modems.

Once set-up is complete, producers must let GrainX know the storage term or market date, and target moisture levels. It can be a moving target if necessary — the team has no problem adapting its work and the AI algorithms to customer needs.

However, time expectations are important to keep in mind becasue it can take between 100 to 150 hours of targeted and controlled fan run time to move one percentage point of moisture and six weeks to complete a conditioning cycle.

Producers must then follow directions from GrainX when it comes time to core, “M” or blend bins to preserve quality. Boisjoli said the cheapest way to reach a target moisture content is to take half a load out of a wetter bin and mix it with half a load of the drier bin.

Norek said this simplicity can have a massive payoff. On Norenda Farms, the system has significantly reduced its grain loss and spoilage.

“I guess our loss went from unacceptable to virtually zero,” he said.

There are still the small losses, such as in the foot of the auger, a leaky tarp or roof or a damaged vent, but Norek said it’s so minimal, he barely counts it, especially compared to their previous losses of entire bins holding 10 or 20 semi loads of grain.