More accomplished per pass | Reducing trips through field saves labour, equipment wear and soil compaction

Until now, precision applications and guidance have had a lesser role in tillage operations, with the exception of strip till systems.

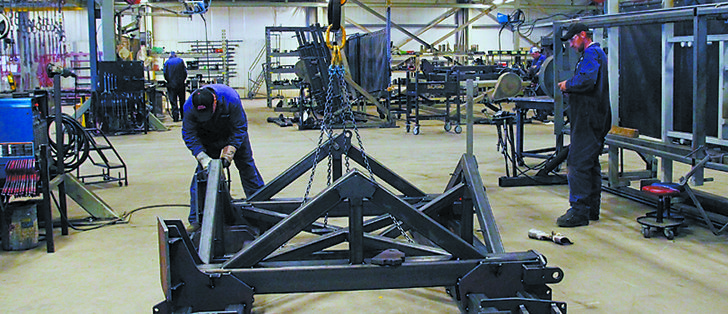

However, Ontario farm equipment manufacturer Salford has attached a set of on-edge shanks to its tillage tools that can be hydraulically lowered into the soil on demand as the conditions warrant.

“You can be addressing issues of compaction in the field, or something like ruts or additional trash that needs more attention,” said Anson Boak of Salford during Canada’s Outdoor Farm Show held in Woodstock last week.

Read Also

Phosphate prices to remain high

Phosphate prices are expected to remain elevated, according to Mosaic’s president.

“You can do it in a single operation by just lowering the hydraulics.”

The active hydraulic, shank mounted chisels can be set to have a trip pressure from 300 to 1,300 pounds for improved leveling or deep ripping. They can be set from four to eight inches in depth.

“Raise the hydraulics and you are back to vertical tillage. You use them only where you need to and where you have planned to,” he said.

The new hydraulic shanks can be added to the existing I model frames and can be placed on 15 inch centres with shanks on the front and rear ranks of the machines.

This allows for every second shank to be lifted for fertilizer banding in 30 inch row corn planting scenarios.

Adding seeding and fertilizer systems to the toolbars can be done by adding coulter type units or the new shanks.

The company is offering kits for anhydrous, dry or liquid fertilizer applications. Broadcast fertilizer systems can also be placed on the toolbars. Heavy duty harrows are frame mounted on most models and add to the coulters’ ability to close the shanks’ furrows.

Mark Averink, who manages engineering and development for Salford, said the company has spent a couple of years on the system in hopes of reducing the number of trips a producer might make through the field to accomplish seeding, fertilizing and seedbed improvement.

He said the tillage pass incorporates fertilizer in a single operation, which helps reduce volatilization losses of nitrogen, saves labour and machine hours and reduces soil compaction.