University engineering teams find ways to come up with bigger horsepower and then test their designs on the track

FARGO, N.D. — Global warming and the energy squeeze are pushing tractive engineers to extract every last ounce of work out of every last ounce of fuel. It’s exciting times for mechanical engineers.

The textbook says traction is the force used to generate motion between a unit and a surface through the use of dry friction. The energy of tractive force is exerted by powered equipment, such as a tractor, measured at the rim of the driving wheels.

The challenge facing engineers is to capture that energy and put it to work.

The challenge facing industry is that engineering students are entering the workforce with little or no practical knowledge or design experience. And they’re expected to design more efficient drive systems for future generations of combines, sprayers and tractors.

To address the concern, industry representatives got together with the American Society of Agricultural and Biological Engineers (ASABE) 27 years ago to promote a hands-on learning program for engineering students.

The ASABE International One-quarter Scale Tractor Student Design Competition was born. The 26th annual event took place this June in Peoria, Illinois. More than two dozen North American universities were represented this year, with Canadian tractors from the University of Saskatchewan and the University of Manitoba.

Teams from 25 engineering departments are tasked to harness the power of identical specified stock engines to maximize performance through a series of performance challenges.

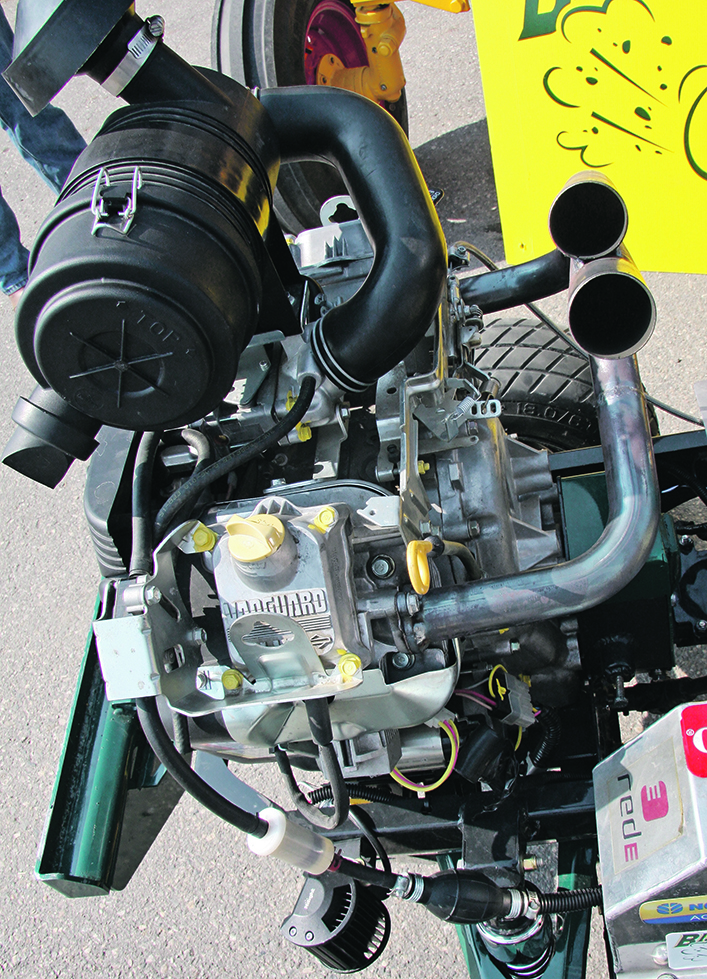

In addition to four mandatory performance competitions, teams will also be judged on fundamentals such as material strength, power transfer, frame, drive train, hitch, clutch and weight brackets. Although the size and shape of the scaled-down tractor is similar to that of a typical garden tractor, very few parts can be used directly from a commercial machine. Most components are custom designed and fabricated by the team.

North Dakota State University displayed its 2022 tractor at the recent Big Iron Show in Fargo, N.D. Nathan Schilling explained the contest rules.

“Each tractor competes in four competitions, but pulling is the main one. Plus, there’s manoeuvrability, durability and a design critique by ASABE engineers,” said Schilling.

“The practical side is that each university must focus on designing a tractor that can be marketed to hobby farmers and home owners. That’s the mandate, not that we ever take it to that extent. It’s a goal we all have. It puts us into a more professional mindset.”

Contest rules say each team must build a new tractor every year. That’s the A Team. The previous year’s unit, named the X Team, is not allowed to compete in the current main contest. The team might have finished a close second place, and with a few tweaks would be a certain winner this year, but it’s back to the CAD for the A Team. The previous year’s tractor is eligible to run in the exhibition class but not in the main contest.

One component of the ASABE reality check is financial. Every team receives an identical Briggs & Stratton 31-horsepower Vanguard engine and a pair of Titan 26 x 12.00-12 TRU POWER tires. Beyond those freebees, the teams go to industry to solicit sponsorship. If the teams’ marketing members are successful, the tractor ends up gaudier than a NASCAR race car.

Schilling says the design justification is almost like defending a master’s thesis. The oral defence takes place before the ASABE panel of judges, who critique safety, ergonomics, serviceability, the ability to manufacture and overall design. The panel does not look kindly on re-using components that were successful in previous years.

“This tractor (on display at Big Iron) had a drive system that worked very well the last two years, so it ended up getting outlawed. We had to start over with an entirely new design. We added a lot of weight for traction and shortened the frame by three feet. We changed the orientation of the engine from transvers to in-line. That meant we had to do another analysis on frame structural integrity.”

When the dust settled, South Dakota State University was the overall winner for 2022 with 2,167 points. University of Saskatchewan was eighth with 2,036 points. North Dakota State University was ninth with 1,931 points. University of Manitoba was nineteenth with 651 points.