Advanced spraying systems have benefits, but they also have costs that must be taken into consideration

Spot spraying isn’t a new idea, and the equipment capable of performing selective applications has been around for decades.

However, the technology that supports this approach is advancing.

Tom Wolf, an application specialist with Agrimetrix Research & Training and Sprayers101, recently shared some of the new research, technology developments, and application techniques during the Western Canadian Crop Production Show in Saskatoon.

Read Also

Saskatchewan puts crown land auction on hold

Auctions of Saskatchewan crown lease land are once again on hold.

The biggest jump has been video processors and graphic processing units, which is the technology that decides whether a plant is a weed, identifies its size and chooses how many nozzles to activate.

“These processors are basically doing calculations where there are hundreds of millions of parameters that they have to solve for in relation to the image that they’ve just seen,” said Wolf.

“They have to do this in 150 milliseconds, because they look about a metre or two ahead. By the time the boom gets there, they have to make a decision.”

However, for this level of the technology to work, someone is required to teach the algorithm how to do this.

Wolf said his colleague Guy Coleman from Copenhagen takes an image of a field about a sq. metre in size and then manually selects the weeds in the image and outlines its leaves and stems. This tedious task is essential to teaching the system how to properly identify a weed.

The process is repeated 10,000 times per weed.

Image processing with algorithms is “full computation,” Wolf said.

The system uses an RGB camera and needs no help from the farmer if he has the algorithm.

This method is one of three ways to perform spot spraying.

The other two ways are reflectance based and an RGB camera that detects rows.

However, unlike with traditional spray systems, it’s not just the machine and hardware that a producer will pay for. Wolf shared that producers will likely also have to pay for access to the software and algorithms to run the spot spray systems.

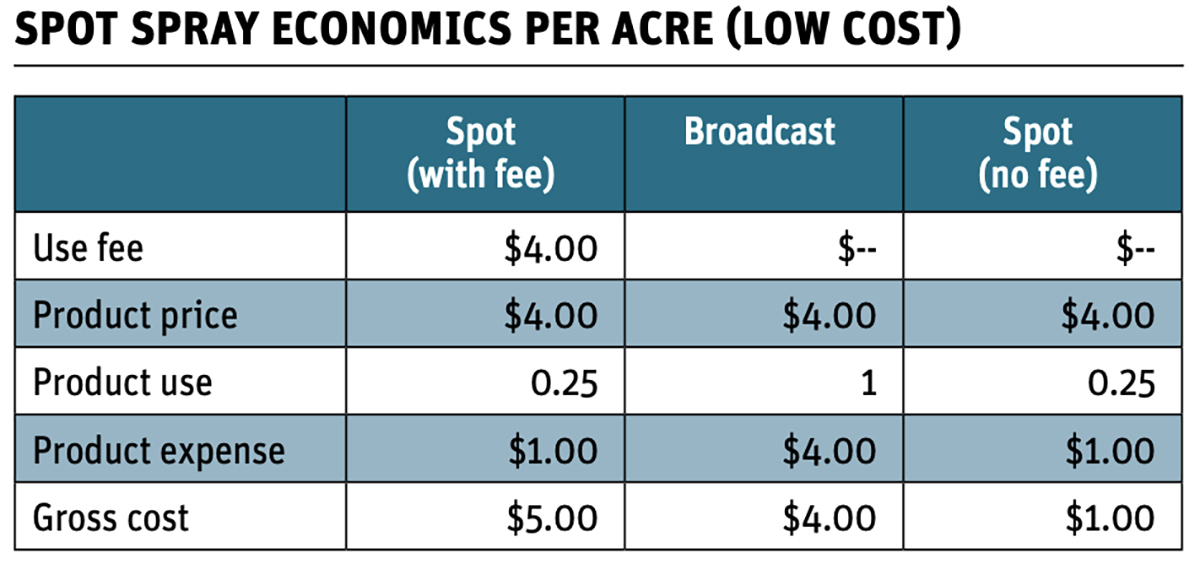

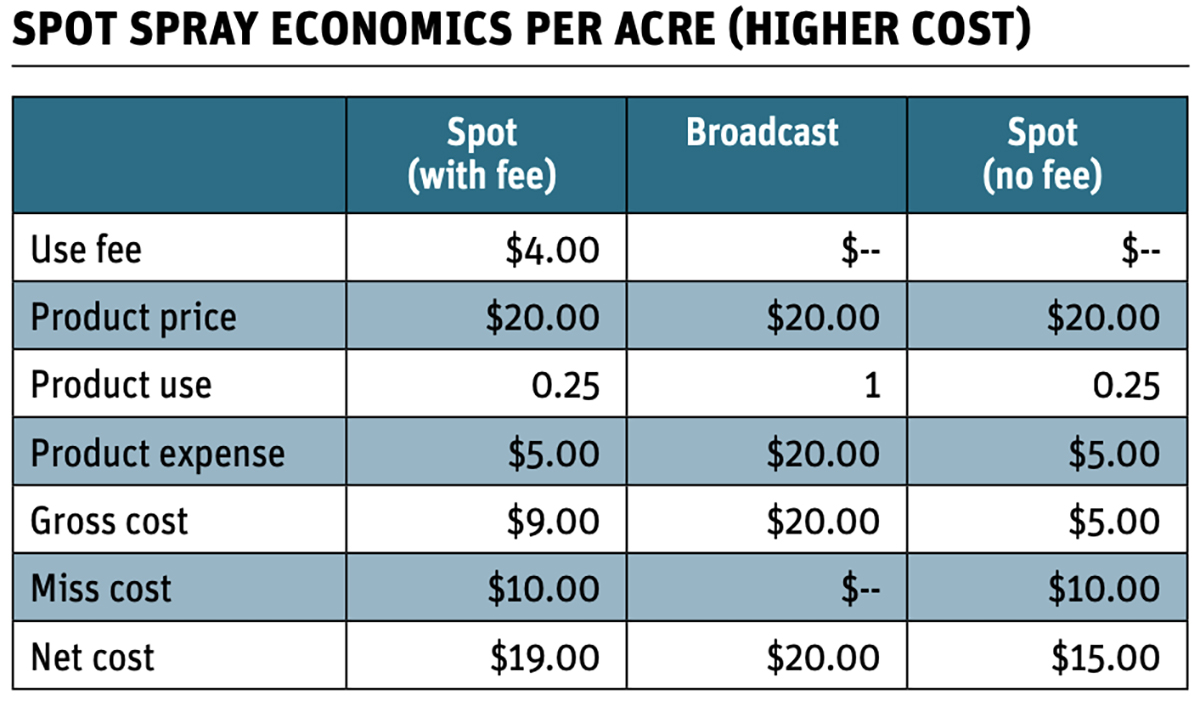

Companies such as Bilberry and John Deere are charging yearly fees to access the necessary software for equipment, he said. Bilberry is running $4 per acre, per year, and John Deere charges for the acres not sprayed.

“You also have to consider cost, like what if you miss? What are the consequences of a miss that we didn’t anticipate,” Wolf said, while posing a hypothetical question to the audience.

“Do you have to spray again? Do you have a yield loss? Do you have a harvestability issue?”

Once everything is considered, there are savings for the produce, but not as much as one may think.

Wolf’s advice is to take the money saved from spot spraying and further invest it in weed control.

He said consistent boom height is absolutely critical for spot spraying.

“If the boom is too high or too low, the camera isn’t sure that it sees what it’s supposed to see and it goes into what we call ‘fallback,’ ” he said.

“So if your boom sways up, all the nozzles go on. It (the camera) says, ‘I can’t see. I’m going to make sure everything gets covered.’ ”

Height and speed are important to reducing sway. It also ensures proper concentration of application and correct overlap for multiple nozzles or if switching to broadcast.

There are some systems that use an overlap mode, where it turns on the target nozzle but also the neighbouring nozzles.

“We’re no longer spot spraying with a band, but rather a broadcast — a mini broadcast screen. Now your overlap issue is more or less gone. On the downside, you’ve used one and a half time more product than you really need to,” he said.

A spot spraying system can be expensive, especially one that runs on software and algorithms, but Wolf shared that it can serve additional purposes. Spot sprayers can be used for herbicides, but also for desiccating crops more accurately, mapping weed species and creating a general weed map.

Wolf said there is economic power in weed maps because they help agronomic decision making for farmers and agronomists alike.

Companies such as SWAT Maps have cameras that can sit atop sprayer booms and then use an algorithm to map weeds.

“From an agronomist perspective, this is pure gold,” Wolf said.

Weed maps are also useful to companies and agronomists to provide further analysis to a farmer. It can offer insight to crop and weed emergence, best application methods and more clarity in target areas.