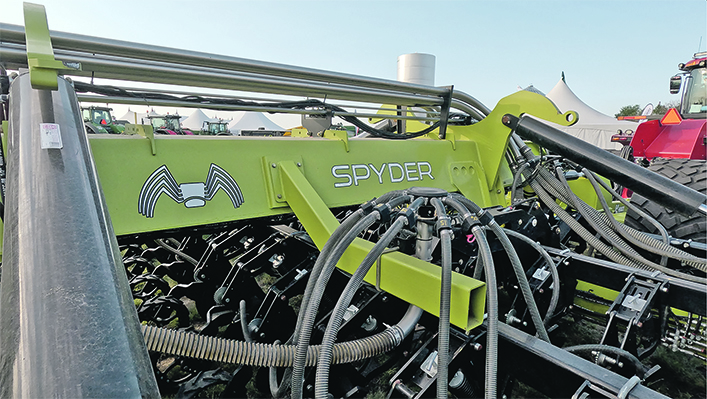

Spyder’s frame continues to evolve so the unit is better able to follow terrain with its spring-based paralink system

The Ag in Motion farm show offered an opportunity to look at different seed drill openers on the market in Western Canada. In this series, we look at opener designs and other new equipment features being introduced for the next growing season.

The folding design of K-Hart’s Spyder drill, which does look a bit like a spider, gives the drill an eye-catching movement when being put into road transport position.

But Scott Ousdahl, K-Hart CEO and sales manager, says producers should pay more attention to the design of the double-disc opener.

Read Also

Trump’s tariffs take their toll on U.S. producers

U.S. farmers say Trump’s tariffs have been devastating for growers in that country.

“I would say the real big value in these drills is the double-disc, undercut opener. The way these work, they basically run straight ahead. They’re mounted on a swivel, so as you turn around sloughs, the seed openers maintain a constant distance from each other.”

The company’s Gent openers use a pair of unequally sized discs tilted to the side to create an angled furrow for seed placement. That helps prevent seed bounce and keeps soil moisture in the trench.

Aside from creating the undercut seed trench, Ousdahl says the double disc arrangement does an exceptional job at cutting through field residue.

“The main disc is running straight ahead and flipped over 22 1/2 degrees to cut and penetrate the soil. The second one is a smaller disc. So whatever that first disc doesn’t cut for residue, the second one shears, because those two blades are just touching each other at the front.

“It opens that trench up, gets rid of the residue, drops the seed in that flap and the packer disc closes it. So, you’re not trying to push dry and wet dirt down. You don’t overpack it. (Seedlings) comes out of the ground really quickly.”

The openers are mounted on swivels so they maintain a constant row spacing even in tight turns.

The Spyder drill uses mid-row banders for fertilizer placement.

“The front row of discs is our mid-row banders,” Ousdahl says. “If you have a machine on 10-inch spacings, the mid-row banders will be on 20-inch centres. We’ve added liquid to our granular application options. We’re prototyping with anhydrous too. So that will be another way to get your fertilizer into the ground.”

The drill is a relative newcomer to the seeding equipment market, he adds.

“K-Hart has been in the disc industry for 30-some years. In 2021 we wanted to take what was a very good opener system and put it in a frame that followed the terrain, gave better ground penetration and we added some new features to it.

“So, in 2021 we launched the new Spyder frame. 2022 was the next evolution of that. 2023 we really got it dialled in. For 2024 and 2025, we’re just at the stage where we’re adding additional features.

“It’s a really fantastic drill.”

To control down pressure, the Spyder uses a hybrid system with adjustable spring pressure on each opener as well as down pressure on gangs that can be controlled from the tractor cab. Together, those systems allow for a lot of vertical travel distance to compensate for irregular field terrain.

“We run kind of a hybrid model. We use a spring-based paralink system with four pressure settings. Usually we’re in those middle two ranges. What that does is most of the work keeping the discs in the ground and the packing pressure as you go along.

“Our paralink has about 11 inches of travel on it, but we have a gang system with load sense on it that we run from the cab. We set the paralinks at neutral based on the pressure, so depth, speed and ground firmness are factors.

“When we dial that in, we have it nice and level. But from the cab we can soften it. At the headlands you can bump that pressure down. So, we have some variability in the cab.

“One of the biggest benefits is that load sense gives you another four inches of down travel if you’re going through a bit of a dip, and there’s about another nine inches of up travel. So it’s about 23 inches of net travel, keeping your seed in the right spot.”

The openers are fitted with a 4 1/2 inch semi-pneumatic packing wheel but the company is testing a ribbed design for special soil conditions.

“The idea on that is for heavy clay conditions for canola, you don’t want to overpack. I still love the smooth, semi-pneumatic 4 1/2 inch, because we’re not pushing dry and wet down, it does a nice consistent packing job. And because we’re not pushing a bunch of dirt, these packers run pretty clean.”