Vantage Ag president Paul Sinkevich is the first to acknowledge that if something seems too good to be true, it usually is.

However, when it comes to the use of nanoparticles in foliar fertilizer applications, he said the proof of the pudding is in the eating.

“We’re adding a process that gets the particle size of the nutrient to only be 30 to 40 times bigger than an atom. You can’t make the particle size any smaller,” said Sinkevich.

It’s cutting-edge technology the fertilizer industry needs because there has been little advancement in decades, he said.

Read Also

Herbicide resistance sprouts in Manitoba’s wild oats

Farmers across Manitoba this fall are gearing up for the latest salvo in what, for many, has become a longtime battle to beat out wild oats.

“The only thing that has been new on the market is trying to improve the efficiency of an existing fertilizer, whether it is a liquid or a granular,” said Sinkevich.

The minute size of the nutrients allows for deep and quick penetration into the plant from root to leaf while application is at a fraction of the rate compared to traditional fertilizer, according to Sinkevich.

“It just changes the ball game now,” he said. “Now we are able to get as much nutrient as we want into the plant in a foliar application and so part of our philosophy is the days of putting down 300, 400 pounds of salt-based inefficient granular fertilizer into your soil hoping to get a crop — those days are gone.”

Sinkevich explained the impact of nano-sized particles abilities using an analogy comparing standard fertilizers as being the size of inflatable exercise balls on a table.

“That’s the current foliar technology that’s on the market – very inefficient, large chunks of nutrient, very small absorption points on the leaf where you get burn from,” he said. “Take those exercise balls off the table and cover it with marbles so now you have a particle size that is at least 420 times smaller. It’s more efficient and you are using way less of the actual nutrient.”

That small size allows for penetration from, “tip to root,” within two to three days, according to Sinkevich.

He said research has yet to be done to see if the nano fertilizer penetrates the soil, but there is no doubt regarding its ability to get into the plant based on tissue sample testing.

The potential for increasing both penetration rates within the plant and improving farming practice efficiencies are striking, said Sinkevich.

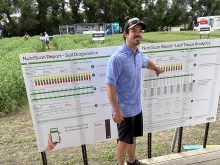

He said one strategy that has worked well with the product involves an early soil test to learn where the field is at nutritionally, a minimal early-season fertilizer application and once the plant is out of the ground, tissue sample the plant to learn where deficiencies are.

“Now you can better utilize that million-dollar sprayer that you have and get out there and mix this stuff whether it is with a herbicide or fungicide. What we are finding is the compatibility with mixing with different products is amazing,” said Sinkevich.

He said the product has been tested on sensitive plants such as tomatoes and asparagus to gauge product safety and has been shown to not damage or burn them.

And the application rate is far less than traditional fertilizers.

“The rates on this stuff is 50 to 80 millilitres an acre,” said Sinkevich, depending on the nutrient being applied.

That rate can significantly reduce costs, he said.