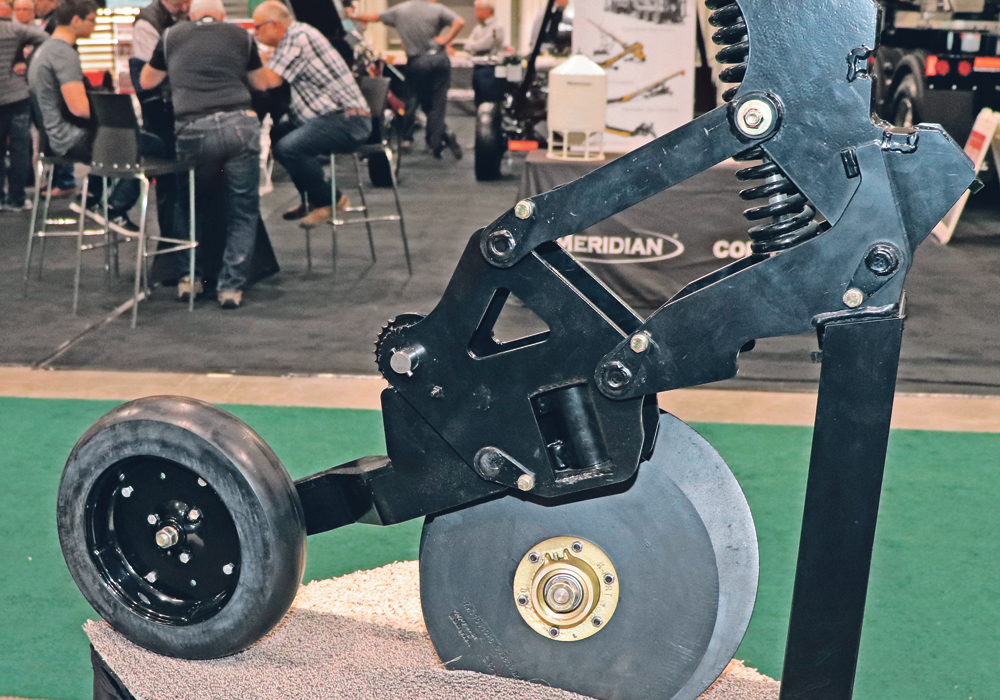

K-Hart industries has come to the market with a low disturbance double-disc opener, but it’s nothing like the double-disc seeder your grandpa used.

The discs on K-Hart’s 8612 opener are different sizes — a 17-inch lead disc and a 14.5-inch opener disc, which enables what the company describes as undercut opener design.

The leading disc leans at a 17.5-degree angle and provides a low ground disturbance cut for which single discs are known.

Some single-disc openers are also known for hair pinning, which is where the second smaller disk comes in.

Read Also

Gene editing digs deeper space in Canadian plant breeding

More Canadian research into crop variety development is incorporating gene editing, and one researcher notes that Canada’s regulatory approach to gene editing will help drive innovation

“You have your 17-inch disk that leads,” Linden Hartman of K-Hart said during the Western Canadian Crop Production Show in Saskatoon last week.

“The 14-inch is coming down right before it hits the ground at the pinch point. It’s actually lifting up that straw instead of trying to cut right through it. We’re just lifting it up and putting the seed underneath, and then it’s coming back down.”

Beyond opening up the soil and residue to provide a consistent seed trench, the second disc also prevents loose soil or straw from falling into the trench before seed is placed on the bottom, which Hartman says enables the best seed-to-soil contact of any disc opener on the market.

To help reduce smearing, where the edge of the seed trench is compacted by a disc, especially in wet conditions, K-Hart uses a pivoting opener that helps the opener run parallel with the direction of travel.

Hartman said the pivoting opener arm also reduces the amount of horsepower required to pull the drill and increases the life of the discs.

Parallel linkage is used on the opener, which provides 10 inches of travel with adjustable spring down-pressure from 120 pounds to more than 800 lb. to match soil conditions.

Many packer wheel options are available, and seed depth can be quickly changed with a quick adjust cam stop setting that moves in quarter inch increments.

The main pressure spring also has five different adjustments.

Double-sided mud scrapers with carbide edges can be flipped for a second use, and triple sealed stainless steel 5206 double ball bearings need to be greased only once per year.

“Disc drills, everyone thinks they are high maintenance,” Hartman said.

“We’re trying to take the high maintenance out of the disc opener. We use different steels that are really strengthened, we use oversize bearings, we use chrome pins. We try to go over and beyond so there isn’t actually a lot of maintenance to go along with it.”

He said operators usually operate the drill at about six to 6.5 m.p.h.

“That’s about a mile and a half per hour faster than traditional seeding units,” he said.

The K-Hart 8612 is a single chute opener designed to provide precise seed placement. For higher rates of fertilizer applications, the K-Hart uses inter row coulters.

“So we’re going to have one mid row feeding two openers,” he said.

“It’s all on paralink out front, and they are all on a hydraulic lift. So if you want them out of the way for a pulse, it’s all hydraulically lifted out of the way, or put back down.”

Hartman said the mid row disc does not have the same pivoting arm that the seed openers have.

“It’s a straight shot disc, so the angle is straight and it’s a little bit of simpler assembly system. It’s not paralink, it’s just a heavy duty single trip system.”

K-Hart offers five tool bars that come in 10 or 12 inch spacing. The 34 and 42 foot tool bars are three-plex that fold once, while the 56, 66 and 76 tool bars are five-plex.

“To pull the 76 foot you’re looking at about a 425 horsepower, but it depends on what size of cart, depends on what type of ground,” Hartman said.

Two rubber options are offered for K-Harts drills.

“We’ve got R-22s, which are the narrower ones, and then we have 500s,which are the big floaters for your wetter conditions, or it’s standard with the five-plex,” Hartman said.

The company is able to match their drills to any air cart on the market.

“We’ve got them all: tow between, tow behind, which ever brand, whichever size,” Hartman said.