Design enables more efficient drying with similar fan compared to aeration systems on flat bottom bins

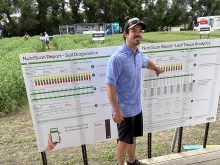

LANGHAM, Sask. — A grain bin hopper with a full-cone aeration system is now available to farmers.

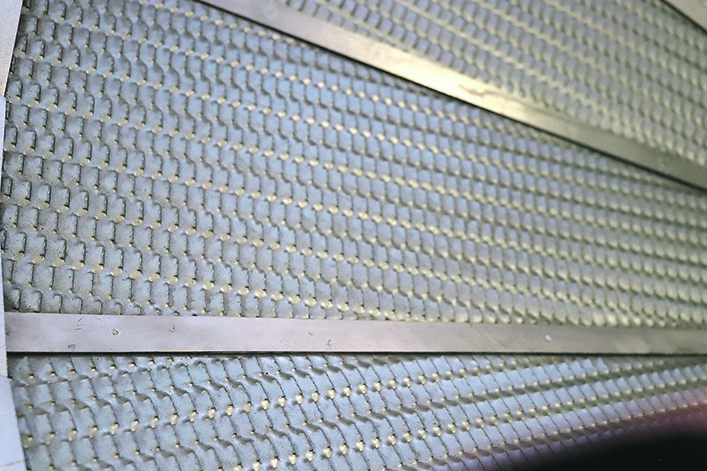

This hopper has a second perforated floor that enables air flow between the hopper floor and the perforated floor. This allows bins only partially full of grain to be aerated, as opposed to some systems where grain must be higher than the aeration towers to work properly.

“That’s something that hadn’t been done before. There are multiple air systems in a hopper bin, but nobody has the whole floor air system,” said Frank Zacharias, owner of NorBin Grain Storage, during the Ag In Motion farm show near Langham, Sask.

“So, we designed the full floor air system for a hopper bin that will aerate all the grain inside of the hopper. You need a lot less air pressure, like static pressure, to produce the same amount of airflow in a hopper bin than you do in a flat bottom bin.”

The hopper has louvers that face downwards, so that the grain doesn’t sit directly on the holes, making it easier for air to flow into the grain.

Zacharias said this enables more efficient drying with a similar fan compared to aerations systems on flat bottom bins.

“We did a test with a 21-foot bin, 8,000 bushels and we put a 10-horse fan on there and we got about 10,500 CFM (cubic feet per minute). So, you get over one CFM per bu. As soon as you’re on top of the one CFM per bu., you actually get some drying done,” Zacharias said.

“If you just want to aerate your bin you can go with less. But if you want to dry down you need to be on top of one CFM or even go to 1.5 CFM per bushel.”

Having a full cone aeration also prevents grain spoilage on the side of the hopper that can stick to the side and be annoying to clean.

The aeration hopper works well with supplementary heating to dry grain.

“You have to add lots of air because you don’t want to just drive the moisture up but not out. So, if you do add heat you want to add like two CFMs per bushel so that you actually push the moisture out the top,” Zacharias said.

The NorBin hopper is built with galvanized steel and it works with any crop commonly grown in Canada.

Because of supply chain issues, the price of the aeration hooper has moved around this summer.

“But I would say if you compared this to a standard, similar-size system, the prices are definitely higher, but if you calculate in the long run, you get way more return for your investment because you save on energy. You can get more airflow with the same size fan,” Zacharias said.

NorBin can retrofit existing flat bottom bins with its hopper, and it can also retrofit existing hoppers with their full-floor hopper aeration system.

NorBin is based in Winkler, Man., and it’s also a distributor grain handling equipment so it can supply entire bins when needed.

The hoppers come in six different sizes: 14 feet, 18 feet, 19 feet, 21 feet, 24 feet and 27 feet.

They are typically shipped in pieces and assembled on-site.