FARGO, N.D. — Farmers who have a serious ergot problem and want to address it right in the field might want to consider the Modular, Portable Air Screen Machine developed by Bench Industries in Great Falls, Montana.

Bench Industries’ Blake Miller brought one of the new trailer models to the Big Iron show in Fargo, North Dakota, to demonstrate how to integrate ergot removal into a field operation.

According to Manitoba Agriculture, ergot results in financial losses through yield reduction, downgrading and outright rejection. In rye, the main host crop, five percent yield cuts are common. In wheat anything in excess of 0.25 percent results in downgrading to sample. Ergot bodies contain toxic alkaloids poisonous to humans and livestock.

Read Also

Fusarium head blight mycotoxin detector in the works

A PhD student at the University of Saskatchewan has been working on developing a method of detecting fusarium damaged kernels to ease the struggles of producers, agronomists and industry.

Miller said versatility is the machine’s biggest benefit. The wide range of screens and adjustments allow the operator to address virtually any crop contamination situation, including ergot, he added.

“For ergot, it’s simply a matter of screen selection, and that depends on the level of ergot. If you’ve got that really big stuff, you can do a real tight scalp and get rid of it,” said Miller in an interview at the show.

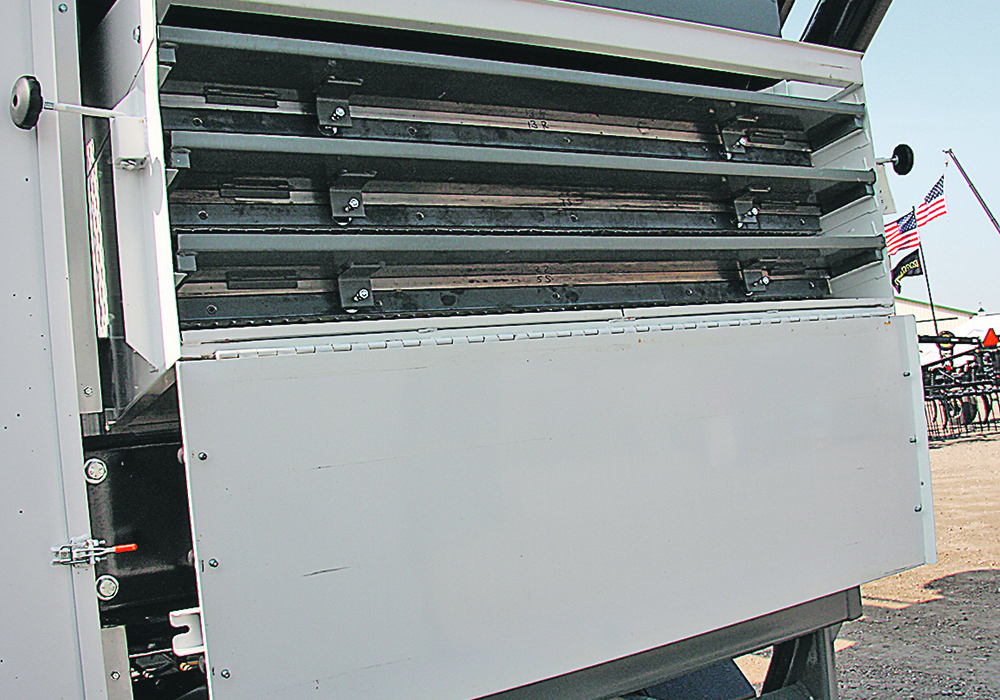

“The way this machine works is we have air sucking before the screen and after the screen. The screen scalps and then sifts. So it picks out the fines. We have balls bounding around under the screen to prevent it from plugging. And we have a hand test kit so we can see how well it performs in any particular setup.

“It’s not perfect. If you have ergot that’s the exact same size as the seed, then you have to move up to a colour sorter. We can set the trailer up so grain comes out of the air screen machine and goes straight into the colour sorter. If you have an ergot problem, there’s really no way around it. You have to do a thorough cleaning before you sell.”

Farmers generally think of colour sorters as a bottleneck because they slow down the process. Miller said that may have been the case at one time, but the trailer-mount colour sorters he has now can keep up with the output from the Air Screen Machine. His company’s biggest sorter handles 1,000 bushels per hour.

“The vibratory feeder is very gentle on seeds. We can say there’s zero percent damage to the crop. At the other end of the scale, the aggressive design handles any kind of rough material.

“Power requirements are low — two horsepower on the machine and five h.p. on the fan. We have a range of screen areas, ranging from 54 sq. feet to 240 sq. feet. Screen area is 162 sq. feet. The 54-inch wide screen can be integrated with other cleaners. Pre-cleaning capacity is 2,000 bu. Actual seed cleaning capacity is 800 bu. Maximum air volume is 7,500 cubic feet per minute.”

Most farmers tick the option boxes for items like the compressor, counter-balancing and dryer, bringing the total cost up to US$200,000. The trailer unit displayed at Big Iron carried a list price of $72,000. Flaman handles Bench products on the Prairies.

Miller said he’d heard a lot of different theories about why the problem varies so much, including moisture, heat, planting dates and the ergot history for a specific region. North Dakota was hit really hard this year, a major increase from 2021, he added.