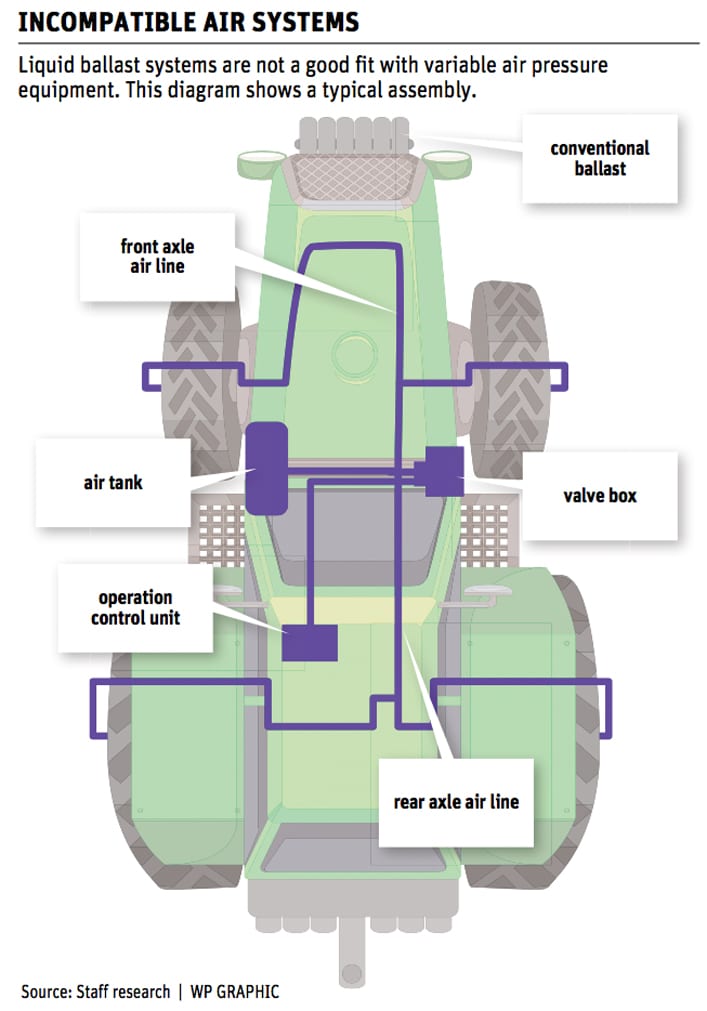

Tire experts say the sloppy slush isn’t intended to work with central inflation systems because of its corrosive nature

LANGHAM, Sask. — Central inflation systems are coming on strong with tire companies designing special CIS tires and equipment manufacturers offering CIS as a factory option.

But what about calcium chloride? How does CIS fare with ballasted tires filled with the sloppy slushy?

Saskatchewan farmer Paul Heglund recently asked us that question in an email.

Heglund wrote: “I find lowering the pressure in a ballasted tractor tire all but impossible and ever so messy. Will it (CIS) swallow and regurgitate the calcium chloride ballast?”

Read Also

Volatile temperatures expected for this winter

DTN is forecasting a lot of temperature variability in the Canadian Prairies this winter. Precipitation should be close to average.

We forwarded that question to leading CIS manufacturers. Here’s what they had to say.

Does calcium chloride mix with CIS?

“No. The tire pressure control system does not ‘swallow’ calcium chloride,” said Les Hinz of Tire Pressure Control International in Edmonton, which has manufactured Tire Boss CIS for ag equipment for two decades.

“The air supply for tire inflation comes from a compressor on the vehicle. When it deflates, it expels the air pressure from the tires out into the atmosphere. So there cannot be any calcium chloride in the tire as it would expel it out through the system. All systems on the market operate in this fashion.”

Agco responded with an explanation from product specialist Kelly Duzan: “For ballast to optimize traction and power to the ground for row crop tractors, the right combination of front weights, wheel weights and proper tire inflation are recommended instead of calcium chloride in the tires. The corrosive nature of calcium chloride causes rims to rust. Putting calcium chloride in radial tires makes them behave like bias-ply tires. The sidewalls become stiff, which narrows the footprint of the tire, creating a rougher ride, less power to the ground and increasing soil compaction. More horsepower is required to push a tire that is ballast with calcium chloride compared to one ballast with cast iron wheel weights.”

Duzan said lower tire pressure in the radial tires when doing heavy draft work allows the tractor to deliver more pulling power with the same engine horsepower. Increasing inflation for on-road applications lowers the tires’ rolling resistance and provides greater driving stability, improved braking safety, longer tire life and fuel savings.

Other respondents pointed out that the latest generation of CIS makes the up-down pressure transition in a matter of minutes. The general consensus is that CaC12 may be on the road to obsolescence.