Late to the party might win a prize this time as the Saskatchewan company says it has learned from others and farmers

Competition in the field of high-speed disc cultivators is heating up with the addition of a new contestant.

Brandt has released a high-speed discer capable of functioning at 14 miles per hour.

The high-speed disc is designed to manage crop residue, condition seed beds, level ruts, reclaim wetlands and generally simplify post-harvest and pre seed operations, according to Brandt’s Scott Lessmeister.

He conceded that the market for high-speed disc cultivators is crowded with good machines, but sometimes being late to the party has advantages.

Read Also

GSI’s GrainVue allows for remote grain bin monitoring

GSI’s GrainVue bin monitoring system allows producers to monitor grain conditions inside the bin and automate any drying, cooling or aerating that is needed to keep grain in peak condition.

“When you’re the last person in the door, you get to see what everyone else is wearing, then you can do them one better,” said Lessmeister.

“We studied what’s on the market right now. Then we did two things. We took the best features and incorporated them into our new design. We also evaluated things that weren’t working so well on competitors’ machines and made sure we didn’t make those same mistakes. So yes, there’s a big advantage being late to the party.”

Lessmeister said Brandt engineers concentrated on things like hydraulic lines, using steel where possible. On a long straight stretch, they run steel instead of rubber. On the hydraulic lines at the hitch, they run on the inner side as opposed to the top, so the hitch stays cleaner. On the frame, the hydraulic lines run on the top so when it’s folded up for transport, accumulated dirt falls away.

“All that sounds like no big deal, but looking at issues like clubroot, preventing cross contamination from field to field with machinery is becoming a serious problem. You want that cultivator clean as possible moving between fields.

“Speed is another big factor. The faster you go, the better these types of machines perform. Eventually, the upper end of the speed range for these kinds of machines will be horsepower. The high horsepower tractors aren’t intended or designed for high speed. When you gear up to reach those higher disc speeds, the tractors simply run out of horsepower.

“We say the new machine can run comfortably at 14 mph. There are some things we’ve done to make that possible. Our rear finishing suspension is something like a trip for the rear roller. When you hit rocks or obstacles in the field, the finishing roller lifts independently of the frame. Without this suspension, the entire frame would lift. The discs lift out of the soil and the shock is much harder on the frame. Any semblance of precision is out the window.”

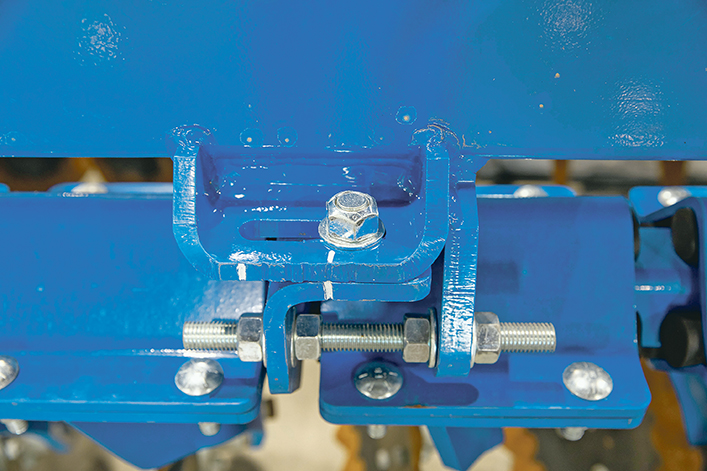

Lateral gang adjustment is another unique feature that coaxes more life out of the front discs. As those front discs wear and the diameter shrinks, they can be moved laterally so they still have overlap. This keeps a very uniform tillage floor and we don’t get the washboard at the bottom of the floor.

“You loosen the nuts on the adjuster then use the two turnbuckles to slide that whole front gang about an inch to two inches laterally. We developed a lot of little things like that, like a bigger foot pad for the front hydraulic jack so it doesn’t sink.

“The engineers designed the unit to maximize uptime with minimal maintenance. They use induction-hardened chrome plate pins, composite bushings with nylon wipers, sealed disc hubs and there’s just six convenient grease points. The independently mounted discs ride in a rubber torsion suspension for consistent ground pressure.”

With an average weight of nearly 1,000 pounds per foot, the new Brandt machine is the heavyweight of the industry, delivering downward force without compaction because of large flotation tires.

Features include hydraulically controlled roller scrapers and accessible down-pressure controls. A variety of disc styles are available in 20-inch and 22-inch sizes.

The new high-speed disc is expected to make its first public appearance at the Crop Production Show in Saskatoon in January.