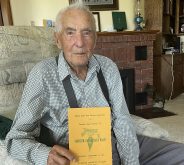

Gary Tokariuk’s farm near Coaldale, Alta., is nearing its centennial.

Tokariuk’s grandfather came to the area in 1910 to work the mines, and in 1928 he bought some farmland.

His father worked that land until his death in 1986, which was when Tokariuk returned home with a degree in agriculture in hand after leaving his job at Alberta Agriculture.

Read Also

Accurate accounting, inventory records are important

Maintaining detailed accounting and inventory records is not just a best practice; it’s a critical component of financial health, operational efficiency and compliance with programs like AgriStability.

Sugar beets have been a welcomed crop in the rotation since the 1940s, but the six-quarter farm has also grown dry peas, beans, barley, hard red spring wheat, potatoes, alfalfa and corn, depending on available moisture.

The farm was recently on display at a harvest field day hosted by Alberta Sugar Beet Growers.

“We’ve grown dried peas, and we put that in the rotation in barley, just when we have years where we have water restrictions,” Tokariuk said.

“Barley and peas can take four to six inches, so we can use the remainder on our sugar beets and potatoes. You have to play this game of what works best.”

This year, the St. Mary River Irrigation District allocated 12 inches to district members, while another six inches of rain fell in July.

The area’s clay soil helps trap moisture better than the sandier land just down the road in Taber and Chin. As a result, his farm did not need to use all its water allocation this year.

“We grow crops that don’t take as much water so that we can move water around,” he said.

“Potato guys also buy water (allocation) from people that don’t use all their water. It’s just moving water to make it work. Like, a wheat crop won’t take as much.”

There has been a 34 per cent drop in allocation quota since the 1998 expansion of the Lantic Sugar plant in Taber. This year, Tokariuk grew 135 acres of the contracted allocation of 22,500 acres.

Last year, he said, 160,000 tonnes were left in the piling grounds that were not processed, necessitating a further drop in allocation for this year’s contract.

Market share was also lost when Coca Cola began marketing U.S. cane sugar in its beverages as part of a fall push from U.S. president Donald Trump.

“We had a new contract this year, and it’s based on the Number 11 sugar price, which is a United States number, based on the U.S. dollar. Because of our Canadian dollar, as long as the U.S. dollar is up where it’s been, has benefited us. If the price goes up, we get more money. If the price goes down, we get less money. The way it is right now, if you check the grain prices, wheat is around $7 a bushel. That doesn’t pay a lot of bills. So beets still look fairly attractive,” said Tokariuk.

“If you’re not happy with it, you can sell your quota. We have that opportunity now where we never did before. If you quit (before), you lost everything. If you want to get back in, which some guys have, you can get back in, so that’s a nice contract right now. It’ll benefit us on a normal year. I guess we’ll just have to decide on a bad year what we do from there.”

Tokariuk has farmed for nearly 40 years and will eventually pass the reins over to his son, Ben, who has a degree in physics.

The fourth-generation farming family hopes to never see a year like 2019, where in the first time in 71 years, 45 per cent of the sugar beet crop was left unharvested due to severe snow and frost in the fall.

Tokariuk recalled the beet-harvesting days of his grandfather, when farmers would dig the beets with a cultivator, pulling them out and leaving them on the ground.

Workers would grab the tops, chop the bottom and clean it off. At night, when the temperature reached freezing, they would pile the beets and cover them with leaves. The next day, they would load them by pitchfork onto a horse-drawn wagon and take them to the packing house.

“If this was the case now, I would be an accountant, a lawyer, or anything but a farmer,” said Tokariuk with a chuckle, noting he much prefers the pivot irrigation controlled from his phone, vacuum planters, defoliators, auto steer/GPS tractors and other technology that allows the farm to dig 20 to 25 acres a day during harvest.

Mono germ seed varieties with coating primer for unified size and weed/bug suppression have also evolved since those early days.

Roundup has replaced micro rates of a cocktail of seven chemicals sprayed numerous times. Now, spraying once or maybe twice has produced the cleanest fields Tokariuk has ever had.

Planting approximately 50,000 seeds per acre on Tokariuk’s 135 acres produces six million beets to be harvested, which results in 600 tonnes of sugar based on 15 per cent extraction.

“We use less chemical,” he said.

”It’s a very safe chemical I would not grow or spray anything on my farm that I wouldn’t serve to my family.”

He said likes to seed on April 27, his mother’s birthday. Any earlier and he risks frost and the need to reseed.