A larger square baler and a new drive concept for farms on slopes are the big winners in this year’s Agritechnica awards.

But the most common theme is greater automation and precision control of machinery from combine headers to fertilizer spreading to managing seeding and planting equipment.

Agritechnica, the world’s largest machinery show, takes place Nov. 9 to 15, 2025 in Hanover, Germany. Its awards are sought after by companies worldwide.

Read Also

Robots, lasers, and AI, oh my!

Advanced field robotics, including laser and high-voltage electricity, is transforming agriculture with AI-driven precision, lower labour costs, and reduced soil disturbance.

The two gold awards and 22 silvers were chosen from 234 innovations approved for the competition.

Gold medal winners:

Claas baler

Claas won one of two gold awards by creating a 70-tonne class baler, which can create eight-foot long bales that weigh at least 500 kg when made of straw. That way, the bales can fit more exactly onto some trailers for more efficient transportation. Typical bales from other large balers on the market range from six to seven feet.

The other dimensions of the bale are four feet by three feet.

The baler has also been designed for high throughput and optimal bale density.

Aebi and AG Maschinenfabrik Line Traction

The other gold medal was won by a joint development called Line Traction between Aebi & Co. and AG Maschinenfabrik and features a new drive system for Aebi’s Terratrac tractors that are specially designed for farming on slopes.

Parts of the traditional differential has been replaced with a hydrostatic system in the planetary final drives. Each wheel of the tractor can then follow the needed speed when turning, with drive shafts always running at the same speed, which improves traction and safety in challenging driving conditions.

Silver medal winners:

Deutz-Fahr tractor assisted guidance system

There are more and more cameras on tractors and Deutz-Fahr is aiming to make them do more valuable work with the development of its tractor-assisted guidance system.

Like many new automobiles, the tractors will be able to stay in lanes, corner with guidance assistance, and recognize people or objects in the way. For farmers who spend a lot of time on the road with their tractors, an advanced option will include adaptive cruise control, collision avoidance, and road sign recognition. The concept was developed with Stereolabs and will be shown for the first time on a tractor at Agritechnica.

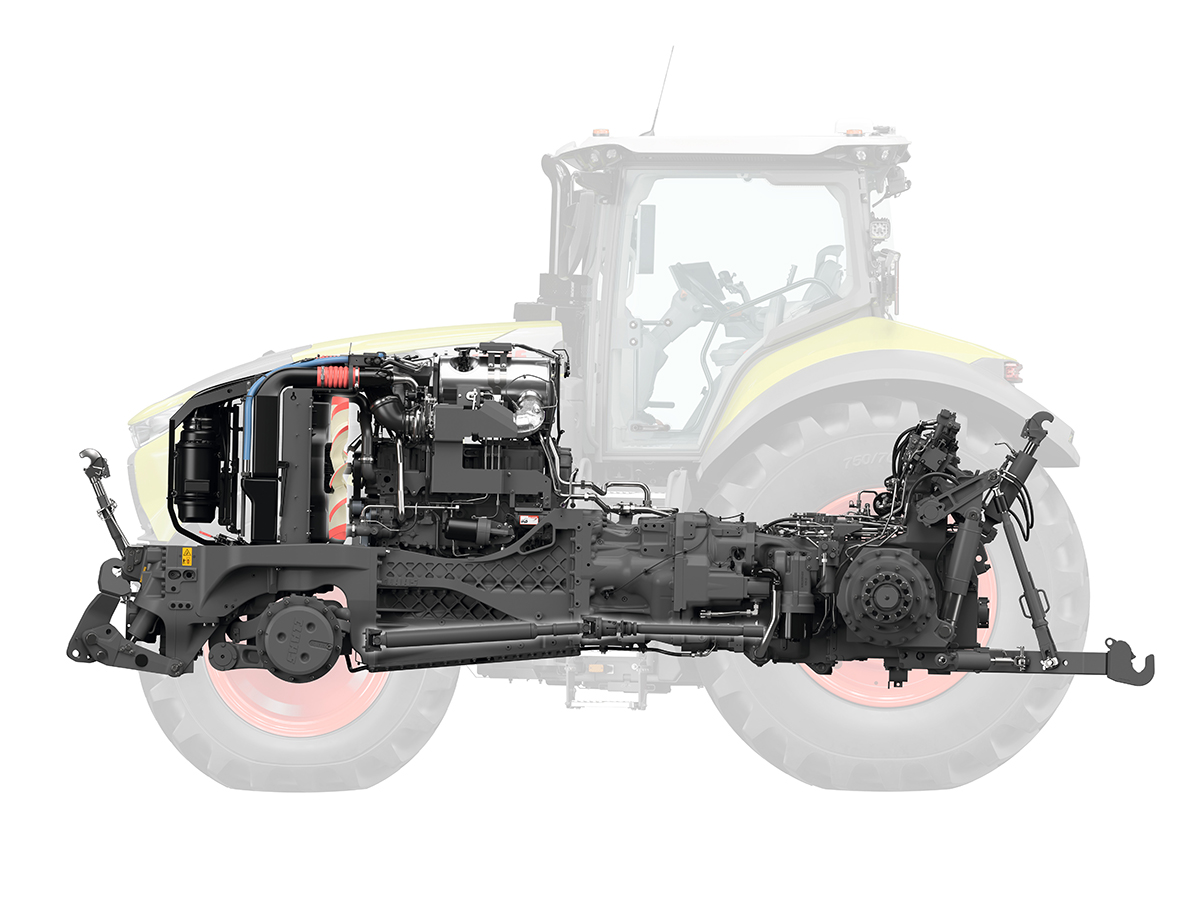

Claas adaptive drive train management for stepless gearboxes

Claas has created an adaptive drive train management system for its Axion tractors, which makes the large machines run more efficiently.

The system learns from the power requirement of the user, and in subsequent operations of the tractor, automatically adjusts the engine speed and gear ratios before load jumps occur.

Grimme easy cleaning for rotary tillers

Cleaning rotary tillers is challenging, which means the job doesn’t always get done between fields in crops like potatoes, increasing the risk of soil-borne disease transmission.

Grimme is introducing a new concept for easier and safer cleaning of rotary tillers.

The company changed the material of the housing to polyurethane so that less soil with adhere to it. The housing can be hydraulically opened, so the user is also provided with unobstructed access to the interior of the housing.

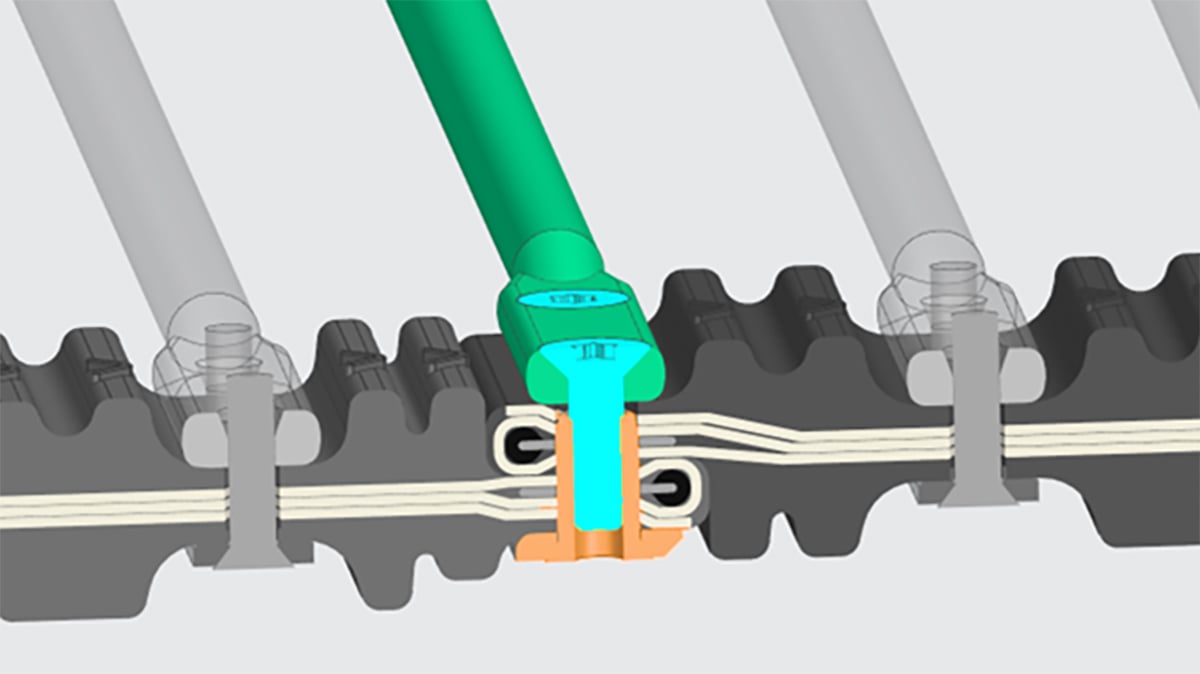

Lemken iQblue Fan Automation and automated fan control

On air drills, the air volume is determined by adjusting the fan speed. Speeds often have to be adjusted during seeding. Fan speeds usually don’t change when lines are blocked.

The automatic fan control system iQblue Fan Automation from Lemken now records the volume of air intake and uses this information as a control variable depending on the floating speed of the seed and fertiliser to be transported and the mass to be delivered per unit of time.

The air volume can also be optimally controlled in the case of implement combinations involving multiple fans. This enables practical, adaptive regulation irrespective of the machine or application.

Rauch Landmaschinenfabrik VarioSmart fertilizer spreading

Infinitely adjusting the spinner speed has long been possible on fertilizer spreaders with a hydraulic PTO drive, but adjusting the speed of both spreading discs or folding deflectors have so far been relied on in fertilizer spreaders with a mechanical PTO drive.

VarioSmart, from Rauch Landmaschinenfabrik, now makes it possible for the first time to regulate the speed of the right-hand spreading disc on a fertilizer spreader with a mechanical PTO drive. This enables more precise distribution of the fertilizer at the field boundary thanks to more steeply descending boundary spreading patterns which reduces the risk of fertilizer granules falling on paths and other non-target areas.

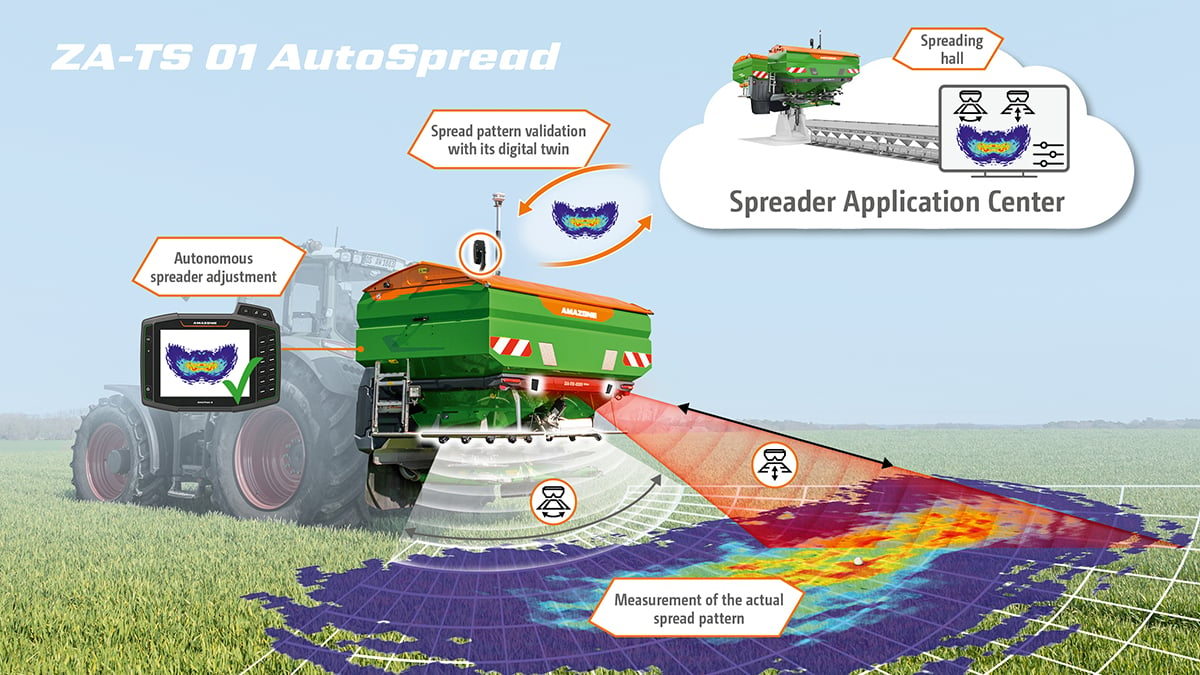

Amazone AutoSpread

A self-adjusting fertilizer spreader is now available on the market for the first time in the form of AutoSpread from Amazone.

The fertilizer’s spread is now recorded via radar on the spreader, meaning testing distribution using a mat or tray is no longer as necessary.

Autonomous spreader settings generate a live-spreading pattern, validated by AI in the field.

Börger GmbH Bioselect RC 250

A new manure screw press allows greater consistency in the final product. That means farmers or custom application operators will know what type of manure will need to be applied and its consistency, including dry matter and fibre content.

The new Bioselect RC250 screw press separator from Börger also helps reduce energy consumption due to several design changes.

Einböck GmbH Smart-Hill

Mechanical weed control is challenged by hills and headlands. The tillage unit being pulled can end up off the row, damaging crops along with weeds.

The Smart-Hil system, jointly developed by Einböck and Claas E-Systems is an innovative extension of the camera-controlled Row-Guard moving frame.

A high-resolution camera analyzes colour and 3D surface models to precisely register the slope. In real time, the on-board computers move the cultivator tines to follow the row at 90 degrees.

Horsch Proactive BoomControl

The new BoomControl system from Horsch optimises the spraying accuracy by analyzing the field surface with 3D radar sensors and using the collected data for proactive boom control.

This minimizes the risk of errors and achieves an optimum spraying distance even on sharply ascending or descending terrain and under difficult conditions.

Geringhoff Yield EyeQ

Geringhoff has developed the Yield EyeQ scanner technology, which uses cameras to evaluate combine grain header losses.

The decision-making support system evaluates changes in the settings of the head, which can then result in recommendations and automation of the header.

Schumacher EasyCut3 (EC3) QuickFit cutting system

Damaged knife blades or guards on the grain cutter bar cause the harvest system to grind to a halt. The person carrying out the repair has to work in the danger zone directly in front of the cutter bar beneath the raised reel.

The EasyCut III cutting system offers hole-free guards and knife blades. The guards and blades are bolted to the frame (cutter bar) or the rod (cutter back) with the aid of adapter plates, resulting in increased stability. During replacement, the patented design means that the fastening nuts located on the upper side only have to be released and removal or insertion carried out from the front. This prevents bolts from being lost and does away with the need for tools to be applied from beneath, thereby increasing installation comfort.

New Holland Corn header automation

New Holland is putting cameras on corn heads to make sure that its headers can keep up with the high throughput capacity of the rest of the combine.

Loss sensors are placed where plants are fed onto the divider hoods. Sensors also keep track of other header measures.

The camera uses an AI system to register the percentage of plants and the proportion of whole cobs or grain that are fed into the combine harvester.

The result of fully automating the corn header is a reduction in pick-up losses of up to 50 per cent.

Grimme Riconda sieve with new connection system

The Riconda modular sieve from Grimme, developed together with Ricon, has elements that are connected using a newly developed locking mechanism consisting of an anchor plate, sieve web bar and two bolts.

The fabric in the belt is no longer interrupted but vulcanised in loops, resulting in a more resilient and easier-to-manage belt.

All of those changes result in significantly lower wear and eliminate the need for segment-specific lock parts.

Krone OptiSet on the Krone Vendro

Adjustments on rotary tedders for hay crops are rarely used, so Krone created OptiSet, so the implement can be adjusted from the cab.

The spreading angle of all rotors can be adjusted infinitely between 13 and 19 degrees with the push of a button. This enables a consistent drying process to be controlled, particularly in the case of heterogeneous grassland growth. The technology enables automatic adjustment even in autonomous operation and contributes to ensuring the efficiency and quality of feed harvesting.

There were three innovations that all were awarded silvers, based on their similar technology for monitoring silage quality on forage harvesters. Real-time corn silage processing scores enable the operator to manage quality as they are cutting corn.

The three technologies include:

- Claas Cemos Auto Chopping

- Fendt – Agco Forage Quality Cam

- New Holland Forage Cam, developed with KU Leuven, Mebios Biophotonics

Claas Jaguar 1000 overall concept

A new forage harvester with more than 1,100 horsepower also has a large 910 mm intake channel and a new cutter drum.

Class’s Jaguar 1000 also includes a new driver assist system and a shorter distance to the crop intake on the chopper head.

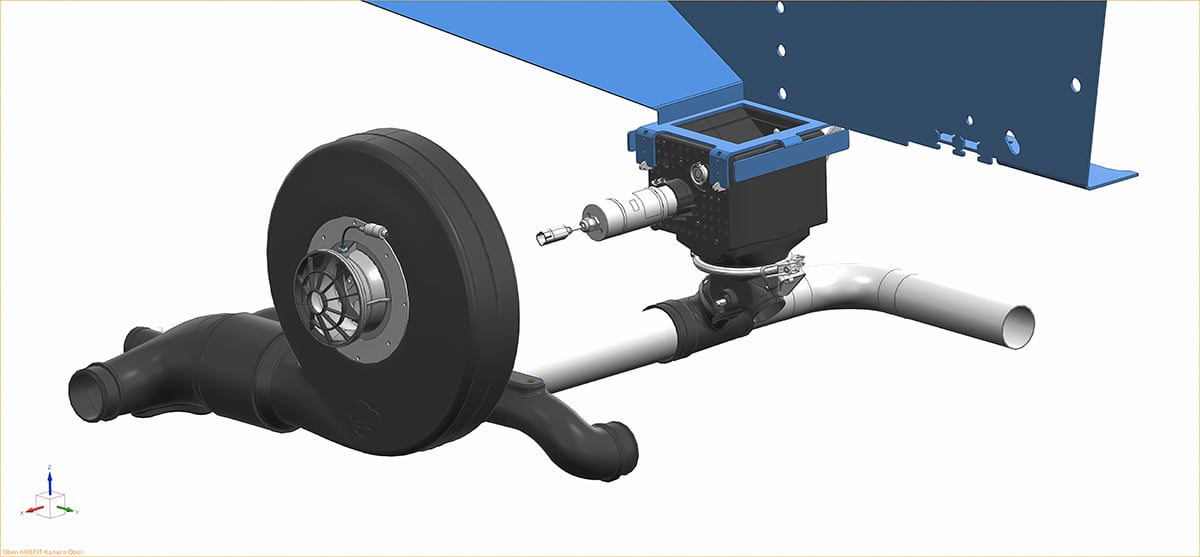

Nokian Intuitu Smart Pressure Assistant for Nokian Tyres Soil King VF tyres

Systems for changing tire inflation for different field and road conditions isn’t new, but Nokian’s Intuitu Smart Pressure Assistant now give recommendations to the operator for the optimum tire pressure depending on the axle load.

This uses the latest generation of tire sensor technology, which can determine the load in just a few minutes while driving.

Another two concepts both received silver medals for their ability to make fertilizer spreader adjustments easier. Both systems use image analysis and AI to determine characteristics of fertilizer and then automatically create spreader settings without spreading tests.

- Amazone EasyMatch, which uses AI to recognize fertilizer

- Sky Agriculture Fertieye, is a smartphone image analysis for fertilizer spreader adjustment under field conditions

Arnold NextG Duxalpha

Arnold NextG has created a 3D mapping system that helps better plan the use of tramlines in fields to guide equipment that will be using those fields.

Elevation and obstacles are automatically considered using the Duxalpha system during planning for tramlines.

The system can also be used to coordinate the movement of multiple machines in the same or nearby fields.