Sulfur doesn’t like to play nice with plants until it is oxidized and ready for uptake; making elemental pieces smaller helps

LANGHAM, Sask. — It takes time and the right environmental conditions for elemental sulfur to oxidize into sulfate and become crop available.

In a perfect world this isn’t a problem because growers can place elemental sulfur in advance on the fields where future crops will need it.

But when environmental and soil factors aren’t favourable, including adverse soil temperature, moisture, and microbial activity, some of the applied elemental sulfur may not be available when needed.

Also, when market conditions change and it’s advantageous for growers to shift their rotations toward a sulfur-demanding crop like canola, the longer lag time between application of elemental sulfur and when a crop needs it can be limiting.

Read Also

Fusarium head blight mycotoxin detector in the works

A PhD student at the University of Saskatchewan has been working on developing a method of detecting fusarium damaged kernels to ease the struggles of producers, agronomists and industry.

To solve this problem Nutrien developed a product that uses micronized sulfur technology (MST), where the elemental sulfur source has been micronized with an average particle size of 15 microns.

MAP+MST includes the micronized elemental sulfur directly in the manufacturing of mono-ammonium phosphate, MAP, granules.

Michel Poiron, who works for Nutrien in Manitoba, said the smaller particle size allows for quicker elemental sulfur oxidation because as particle size decreases, the surface area increases.

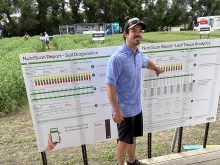

“The oxidation rate will be much higher, which means that it will become more available within that season. With the elemental incorporation the salt index isn’t really affected as if we would make that analysis more of a sulfate form of sulfur versus the elemental,” Poiron said at the Nutrien booth during the Ag In Motion farm outdoor farm show held July 19-21 near Saskatoon.

MAP+MST is a 9-43-0-16S fertilizer that offers a slow release throughout the growing season and is safe to apply in the seed row. The formulation also decreased sulfur loss due to leaching.

“You’ve always got to follow the seed safety provincial guidelines, in regard to phosphate rates in the seed row. But what we’ve recognized with our product is because we’ve been able to reduce the amount of salt in the product, our seed safety seems to be superior to any other product and in the industry right now,” Poiron said.

He said MAP+MST can be used with many crops, so it provides growers more flexibility when it comes to the logistics of having the right fertilizer ready at the right time in the spring.

“Normally, you would pick up a specific fertilizer blend for that specific field,” Poiron said.

“But because of the analysis and the nutrient density you can go in several different crops without having to change the product in your truck or in the tank of your air cart. So whichever field is ready first in the spring, you’ve got the right product in the tank.”

Using MAP+MST can provide a big help when switching crops, because growers don’t have to worry about finishing a field empty or cleaning out compartments in the air cart.

MAP+MST is a nutrient-dense product.

“It’s so packed with nutrients that the amount of total pounds per acre that he needs to apply is a lot less than other conventional fertilizers. So, the growers’ efficiencies are much higher because he doesn’t have to fill as many times during a field,” Poiron said.

Another advantage MAP+MST has over some other traditional fertilizer products is its storability because the amount of moisture it accumulates is limited.

“This gives the growers the opportunity to participate in buying this product when they feel it’s the appropriate price for their farm and then store it on the farm,” Poiron said.

“You can avoid long lineups at the retailers if you have some product on farm and avoid all those potential bottlenecks at some facilities by picking up your fertilizer at that a different time.”

When the nutrient density of MAP+MST is taken into consideration, Poiron said it typically costs about $40 dollars per tonne more than monoammonium phosphate 11-52-0.