Last year reminded us that, even with the dominance of reduced tillage, drought still pushes dirt into our air and into the filters we expect to protect engines and our lungs.

New Holland filter engineer Aaron Booth says the three prairie provinces were especially hard hit with dust last summer, and he fears the climate forecasters will have even more dust in store for farmers. That means more dust to clog filter membrane material, allowing more dust to enter the combustion chamber and the cab.

“It all comes down to diligently checking those air filters regularly,” said Booth in a Zoom interview, adding that neglected filters can cause costly repairs.

“If an air filter needs to be cleaned or replaced, there will be an indicator in the cab. If an engine or hydraulic filter clogs, the machine will shut down. You would not want to run for any amount of time with clogged filters.

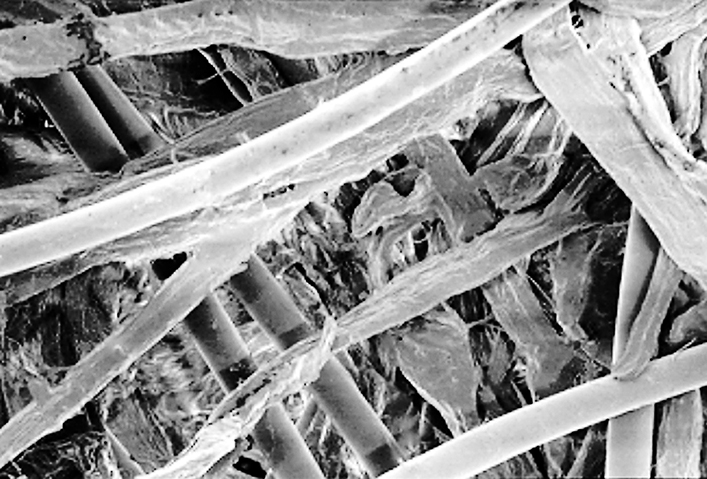

“We use a filter membrane media called MicroLoc, which is a synthetic material. The fibres inside allow oil to flow faster so the friction surfaces always have adequate supply. Whereas most of the aftermarket filters use a paper cellulose material, which don’t last as long. The material doesn’t stand up as well as the fibres. When oil and hydraulic filters start to plug, components don’t receive the full flow they need.”

Booth says NH has run extensive field tests comparing the company’s OEM filters to aftermarket filters. All four types of NH filters exceeded the performance of aftermarket filters.

- Air filters are three times more efficient than conventional filters. Engine air filters limit the amount of dust entering the engine to less than one gram in 500 hours of operation.

- Engine oil filters provided 60 times more contaminant protection.

- Hydraulic oil filters had 20 percent higher dirt-holding capacity.

- Fuel filters had double the dirt-holding capacity.

“We see the lower priced filters with the same specs as OEM filters. But when we open them up for analysis, we see that the cheaper filter doesn’t last as long. The membrane doesn’t last as long. It’s not doing its job for the prescribed number of hours.

“The real difference is that each NH filter has been field tested for that specific machine. It’s gone through all the punishment over and over, then analyzed, then modified to meet the needs of a particular tractor or combine. The aftermarket filter is more generic. It fits a list of different machines.”

For new machines the hydraulic oil recommendation is to change the fluid shortly after a few hours, after which time the intervals are quite long, provided the filters are changed according to the schedule.

“Fluid filters for hydraulics or engines must have a high dirt-holding capacity. That’s their job, to keep the particles from wearing on internal surfaces. If a filter can’t retain the dirt, then it’s not doing its job.

“The specs on a new OEM and a new aftermarket fluid filter may read the same, but after a period of time, the cheaper filter starts to let particles through.”

Booth says farmers may view their cab and engine air filters differently than they view fluid filters. When you remove any type of air filter, you can blow out the dust and visually perceive how much soil you’ve captured. There’s no such visual indication with fluid filters, so operators typically take air filters more seriously.

“You can take the used air filter and hold it up to the light next to the new filter, and you can really see how well it’s been catching dust. You can also visually compare a new OEM construction and materials to aftermarket construction and paper materials. There’s a big difference.

“Diesel injectors and pumps are very sensitive to fuel quality. The injection system is called upon to perform at a high level in order to keep the modern diesel running as intended. There are issues such as diesel fuel gelling and plugging the components. You need a quality filter to keep contaminants out of the system. Same with hydraulic systems. They’re becoming more sophisticated.”