Malfunctioning or partially plugged sprayer nozzles can be difficult to detect, costly and embarrassing when they act up beside a busy road.

Intelligent Ag recently launched a product called Recon Spray Sense that help alleviate these concerns.

“It’s the first time that anybody’s really doing any kind of monitoring right at each individual nozzle,” said Alan Macdonald of Intelligent Ag.

“It’s ground-breaking in that sense because most monitoring systems right now are kind of an aggregate for the spray and not individual nozzle monitoring.”

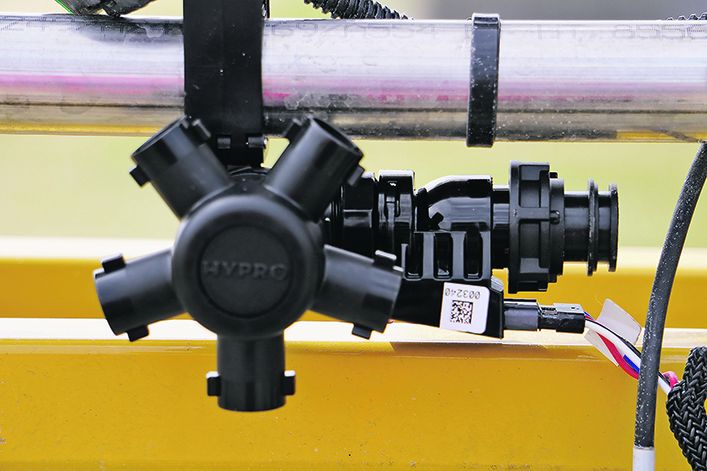

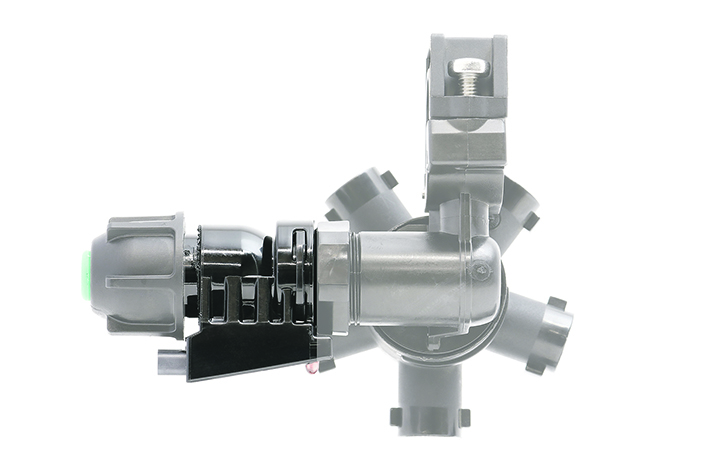

He said the aftermarket, spray-quality monitoring system watches the rate and flow at every nozzle tip with a mechanical sensor that attaches between the nozzle body and the check valve.

Worn nozzle tips with slightly altered performance are difficult to identify, but they can affect a sprayer’s performance.

“The only way that you can identify them accurately is to do a cup test where you’re running water through the sprayer, to measure the amount of product that’s coming off of each nozzle tip,” Macdonald said.

“From the operator seat, it’s almost impossible to be able to see when you have issues.”

Recon Spray Sense can identify all worn or blocked tips, and it can identify intermittent blockages in recirculating booms where there’s foreign material moving from one nozzle tip to another.

“We would be able to see that at each tip (intermittent blockage). So, what you’re able to do is set parameters on the system that are based on the nozzle tip that is being used,” Macdonald said.

“From that selection we’re able to determine what the desired rate and pressure should be for that nozzle tip. Any deviation from that and we can show that there’s an issue.”

There are more 1,200 different spray tips available in the Recon Spray Sense database.

An iPad is used for the user interface in the cab and it doesn’t have to be integrated with any other control system.

A harness connects all the sensors on the boom to a gateway that uses a wi-fi signal to communicate with the iPad.

The system can support any sprayers on the market.

On the iPad, there is a dashboard view that provides an overall look at sprayer performance.

“One of the things that we highlight is what we call a spray quality score and what it is based on is the overall performance of all those nozzle tips over a period of time,” Macdonald said.

“It’ll measure the number of acres that are covered, how close you were on the proper pressure that it should be operating at for that spray tip, the amount of gallons per acre that should be put on for that tip that you’re using. That’s how we determine the quality score.”

Another dashboard view shows droplet size, pressure, the rate being applied in gallons per acre, as well as the flow in gallons per minute.

In a detailed view in the user interface, the sections on sprayer are displayed and if there’s an alarm it will show up visually.

“If you see those alerts, you can drill down to that section in which case it will then expand across the screen to show all of the particular tips on that particular section and show you what they are operating at in terms of the PSI (pounds per square inch) and gallons per acre… and how close we are to being on target for each tip,” Macdonald said.

He said when the company was in the design and research stage for the device, it found that a lot of operators and producers do not fully understand the impact of worn nozzles or intermittent blockages.

“We tend to think that being close is good enough, but you know it does have an impact,” Macdonald said.

“Certainly, on weed resistance, which is becoming more and more of a concern, that can have a fairly significant financial impact to producers if they’re having to change varieties and change rotations.”

He said Intelligent Ag conducted field tests last summer with the Recon Spray Sense system. A limited release is planned for this spring with a full release with more models later in summer.