Manufacturers are looking to shave every possible pound from seeding equipment, sprayers, combines, swathers and grain trucks. Less weight in ag implements translates to more payload or less soil compaction.

New nanocrystalline super-alloys from a Massachusetts company called Veloxint may some day cut the weight of farm implements in half. We’ve already accepted spray booms made with aluminum or carbon fibre and aluminum pickups. Every time implement weight goes down, farm efficiency goes up.

“With these alloys you could make the entire sprayer 40 or 50 percent lighter. That would let you reduce ground pressure, reduce compaction and increase capacity,” says Scott Day, representative for a California company called Fall Line Capital, which invests in ag technology. Day also runs the family farm at Deloraine, Man. Fall Line Capital invested in Veloxint a couple of years ago.

Read Also

Robots, lasers, and AI, oh my!

Advanced field robotics, including laser and high-voltage electricity, is transforming agriculture with AI-driven precision, lower labour costs, and reduced soil disturbance.

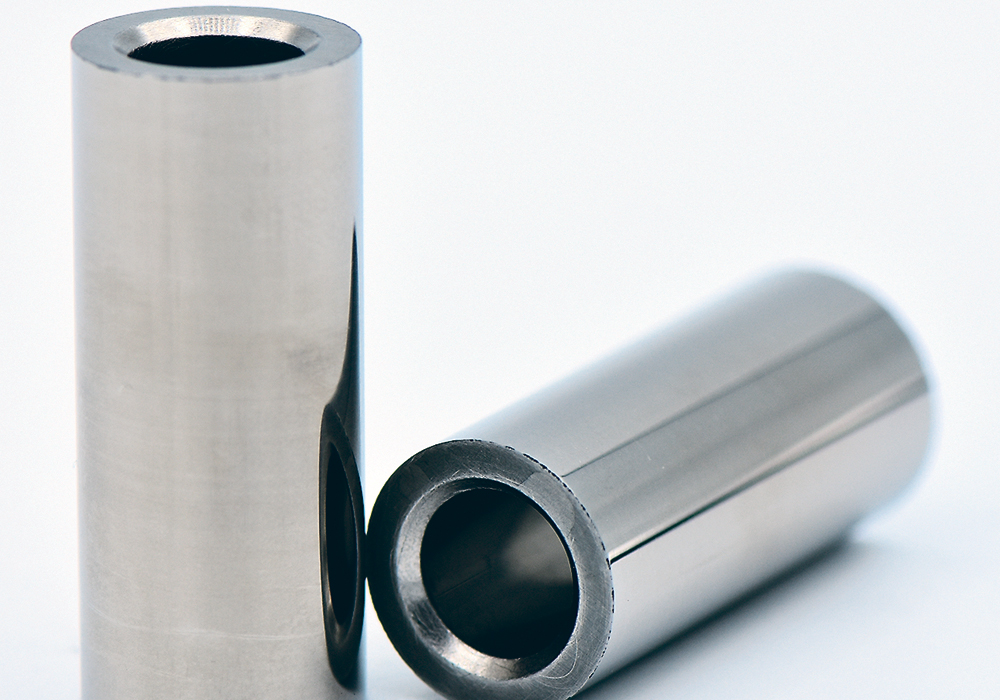

“You could make equipment components that last much longer than anything we have today, things such as discs, cultivator shovels and hoe points that would last a generation or more, even in abrasive soils. Combine parts such as feeder chains, rub bars and chopper blades would last exponentially longer. Engine components would last multiples of what they do today.

“Grader-scraper blades would last months instead of days. We could have trailers and trucks 50 percent lighter so they can carry more raw product, be easier on our rural roads and burn less fuel. This would be one of many categories where the CO2 impact would be reduced.”

Day says the first question will be, “but what does this all cost?” There are factors weighing in favour of keeping Veloxint nanocrystalline (NC) alloys costs low. The basic raw ingredients are essentially the same as what’s already used in steel or aluminum. He says the process will become less expensive as it goes to a larger scale.

“Even today in its infancy, the cost/benefit ratio will be much better with a Veloxint component than a conventionally available component. Another factor is the time savings of not having to change components as often.

“It’s expected that this new material will 3-D print better than conventional metals. This is important in agriculture where component volumes are sometimes very small or fabrication machine shops no longer exist.

Veloxint materials should allow for the production of unique and complex parts with greater precision and less cost. Any farm component restricted in its life cycle because of wear or fatigue will benefit.”