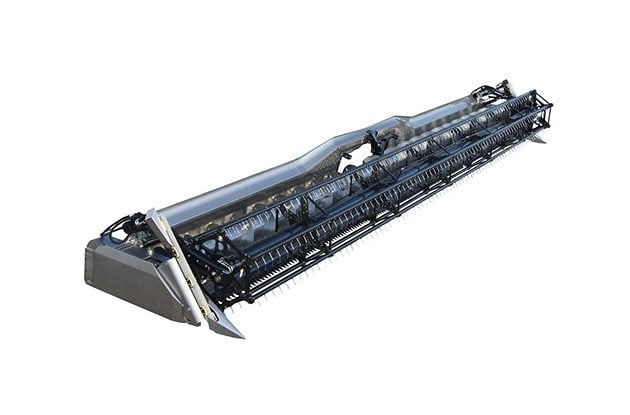

The Biso Ultralight 800 header can switch from harvesting cereals to canola in minutes

Canadian canola producers are increasingly interested in straight-cutting canola.

New technology, such as shatter resistant varieties and new chemicals to desiccate the crop, has spurred the movement.

However, when it came to headers that can efficiently straight cut canola, new designs didn’t have to be developed because they could be imported from a region that has been straight combining rapeseed for decades.

Producers in Austria have straight cut the crop since the late 1960s, said Robert Breckner of Biso Canada.

“That’s all what they do over there, so there’s quite a few companies that make headers,” he said.

Breckner exhibited a 35 foot Biso Ultralight 800 header at Canada’s Farm Progress Show earlier this year in Regina, where the company was awarded a Sterling award.

Producers looking for a header to use for straight combining canola should be interested in the header’s ability to switch from harvesting cereals to canola in minutes.

Read Also

U.S. softens fees on Chinese shipping

The U.S. starts charging new fees on Chinese ships on Oct. 14. What are the ramifications for their ag exports?

It has a variable cutter bar that enables operators to move the knife forward or back 800 millimetres and hydraulic-folding side knifes to help cut through canola stands.

Crop dividers on the header must be removed and placed on a bracket on the header transport trailer when switching to straight cutting canola, but this procedure takes only a few minutes.

The header is made of aluminum with high strength steel and stainless steel, which helps reduce its weight and allows for a cutting width up to 16 metres.

Breckner said the 35-foot header that was on display weighs 7,500 pounds. The intake auger and variable bed are made of stainless steel, which helps the flow of material into the combine.

“Stainless steel auger, stainless steel floor. This way you have nice smooth feeding,” Breckner said.

“And we can also adjust the pitch of the header. If you have a large crop, you tilt it forward, and regular crop you just run it flat.”

The split knife and auger drive, where knives and augers are driven from both ends of the header, reduce vibrations in the header.

“Both sides are driven so you have two wobble boxes, there is also wrap protection if you want to straight cut oats,” Breckner said.

Splash guards are included to reduce grain loss around the feeder house. Breckner said the header can be used with North American combines.

The header displayed at Farm Progress sells for $95,000.

For more information, Breckner, can be reached at breckner@goinet.ca.