A chain is only as strong as its weakest link, as the saying goes, and a combine is only as efficient as its most inefficient component.

New Holland’s latest contribution to the global body of combine knowledge is a pair of new draper headers, the 840CD rigid and the 880CF SuperFlex.

The engineering trick that makes these drapers unique is removing the cutterbar gearboxes from the ends of the header and then hiding a single cutterbar gearbox under the centre of the header.

Read Also

Proposed dicamba restrictions please expert

Pest Management Regulatory Agency proposes banning “over-the-top” spraying of dicama on soybeans.

This reduces vibration and grain loss, according to New Holland’s Nigel Mackenzie. He says the new draper headers have been developed in response to the growing demand for larger, more efficient headers.

He says the new technology is driven by farmer’s desire to go wider, which started in the mid-1990s when combine efficiency started to accelerate.

More recently threshing capacity jumped, hoppers got bigger and horsepower surged upward. Until then, the headers had been adequate. Suddenly there was a new weakest link in the chain.

The trend became wider headers that were capable of feeding bigger combines at slower field speeds.

But building an auger head in the range of 40 to 45 feet turned out to be an engineering nightmare, especially for flexing units.

“If your auger isn’t set up correctly, you get material flying around and dropping to the ground. If you’re in really ripe crop, the auger is more likely to knock grain forward down to the ground.

“But with a draper, if you’re in really ripe crop, all that shelled out material just gently drops down to the belts and into the combine. The draper reduces your grain losses compared to an auger. As for the quality of the crop, I’ve never seen any difference.”

Mackenzie says there are occasionally conditions when an auger might do a better job handling a difficult crop, but the draper typically feeds the crop more uniformly.

“In the past, the higher cost of a draper kept a lot of farmers away. There are a lot more moving parts, so that costs money.

“When profit margins were tight, the cost differential pushed people toward the augers. But in the past few years, the extra money has been there, so guys are investing in better headers.”

The most distinguishing factor that sets the 840CD and 880CF headers apart from other headers is what you don’t see.

For one thing, you don’t see drive components at the ends of the header. As a result, you don’t see bulky protective shields. The slender ends on the 840CD and 880CF slice through standing crop with minimum crop damage.

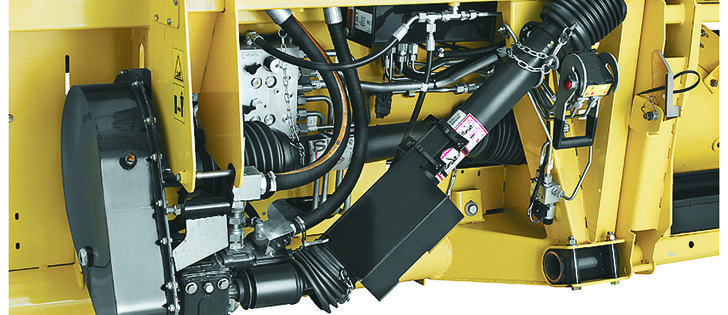

The lone gearbox is the other important component you don’t easily see. It’s hidden and protected by the wear plates up under the draper, where it drives the cutterbars without impeding movement of the belts.

“This is an extremely low-profile design. There are only two intermeshing gears. It’s hydraulic drive, so we have no chains or driveshafts or belts. It eliminates vibrations by keeping the two opposing knives perfectly synchronized.

“This design reduces the total amount of weight we carry on the header, and the remaining weight is now concentrated at the centre, right in the middle and low to the ground. It makes the combine handle much better.”

The corporate policy of not developing equipment for sale to outside parties added to machine efficiency.

“That eliminates any need for us to have transitional hardware or spacing. Our headers mount closer to our feederhouse for maximum efficiency.”

The New Holland combines know when the machine has stopped and reversed. “When you start up and in-feed again, the centre draper runs first to clear itself, then there’s a time delay before the side drapers go.”

The 840CD rigid draper is available in widths from 25 to 45 feet. The 880CF SuperFlex draper provides ground-hugging flotation and is available in cutting widths from 30 to 45 feet.

New Holland says a slow speed transport kit is available, using wheels that fold down hydraulically from the combine cab. A transit process once requiring two people, a trailer and a tow vehicle can now be handled by one person and the combine.