Fertilizer is one of the most significant expenses for farmers, but it is also essential for maximizing yield and crop quality. In recent years, fertilizer prices have become increasingly volatile due to supply chain disruptions, transportation costs and fluctuating natural gas prices.

Genesis Fertilizers is addressing these challenges head-on by proposing to build a state-of-the-art, farmer-owned nitrogen fertilizer facility that will return urea margins back to the farm and ensure a reliable, locally sourced supply.

“This project makes economic sense given today’s market conditions,” says Barrie Mann, vice president of investor relations at Genesis Fertilizers. “Canadian farmers pay some of the highest fertilizer prices in the world. There hasn’t been a new nitrogen plant built in Western Canada in 35 years, and the time is right to establish a farmer owned, locally controlled supply.”

Barrie Mann, vice president investor relations, Genesis Fertilizers.

Barrie Mann, vice president investor relations, Genesis Fertilizers.

A strategic investment for Canadian farmers

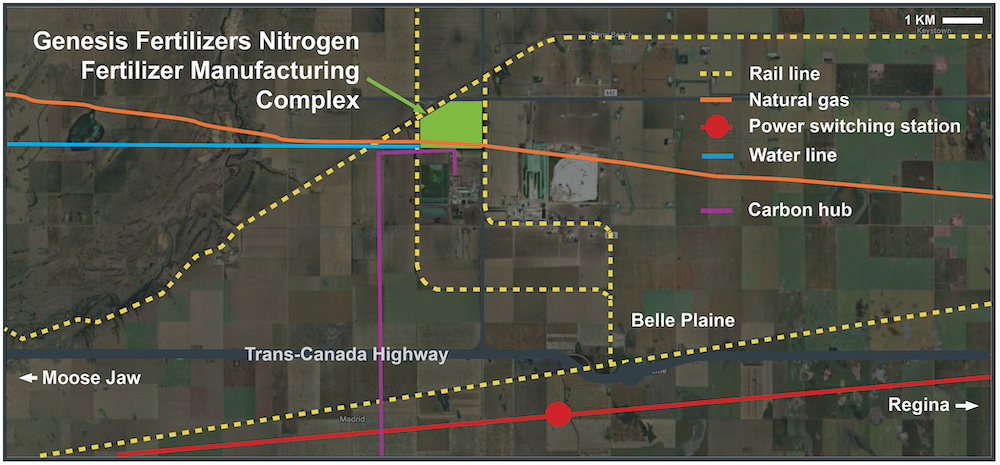

Located in Belle Plaine, Saskatchewan, the estimated C$2.3 billion Genesis Fertilizers project is designed to meet the nitrogen fertilizer needs of Canadian agriculture. This initiative includes both a world-class production facility and a network of strategically located, farmer-centric distribution centers to streamline access and logistics.

By leveraging Western Canada’s cost advantages, the facility will operate with low production costs and the ability to ship the fertilizers directly to the farm.

“The cost of importing fertilizer is extremely high,” says Mann. “Western Canada has access to reliable, low-cost natural gas, stable water resources and dependable energy infrastructure. By producing fertilizer locally, we can eliminate many of the market-driven cost increases and pass the production margins directly to farmers.”

Farmer-owned, vertically integrated and profitable

Genesis Fertilizers is pioneering a vertically integrated, farmer-owned model that is a first for fertilizer production in Canada. This structure allows farmers to invest directly in the plant by purchasing units equivalent to their annual fertilizer usage.

An estimated 75 percent of the facility’s production will be secured through farmer off-take agreements, ensuring farmers receive the production and distribution margins, along with supply security. The other 25 percent will be sold on the open market.

“This structure gives farmers direct ownership and control over their input costs,” says Mann. “There’s no way to reduce costs at the retail level, so the only viable way to lower expenses is to have ownership at the manufacturing level.”

Sustainability at the forefront

The Genesis Fertilizers plant will set a new standard for sustainable nitrogen production, incorporating cutting-edge technology to reduce greenhouse gas emissions, utilize renewable-based hydrogen, and integrate carbon capture solutions.

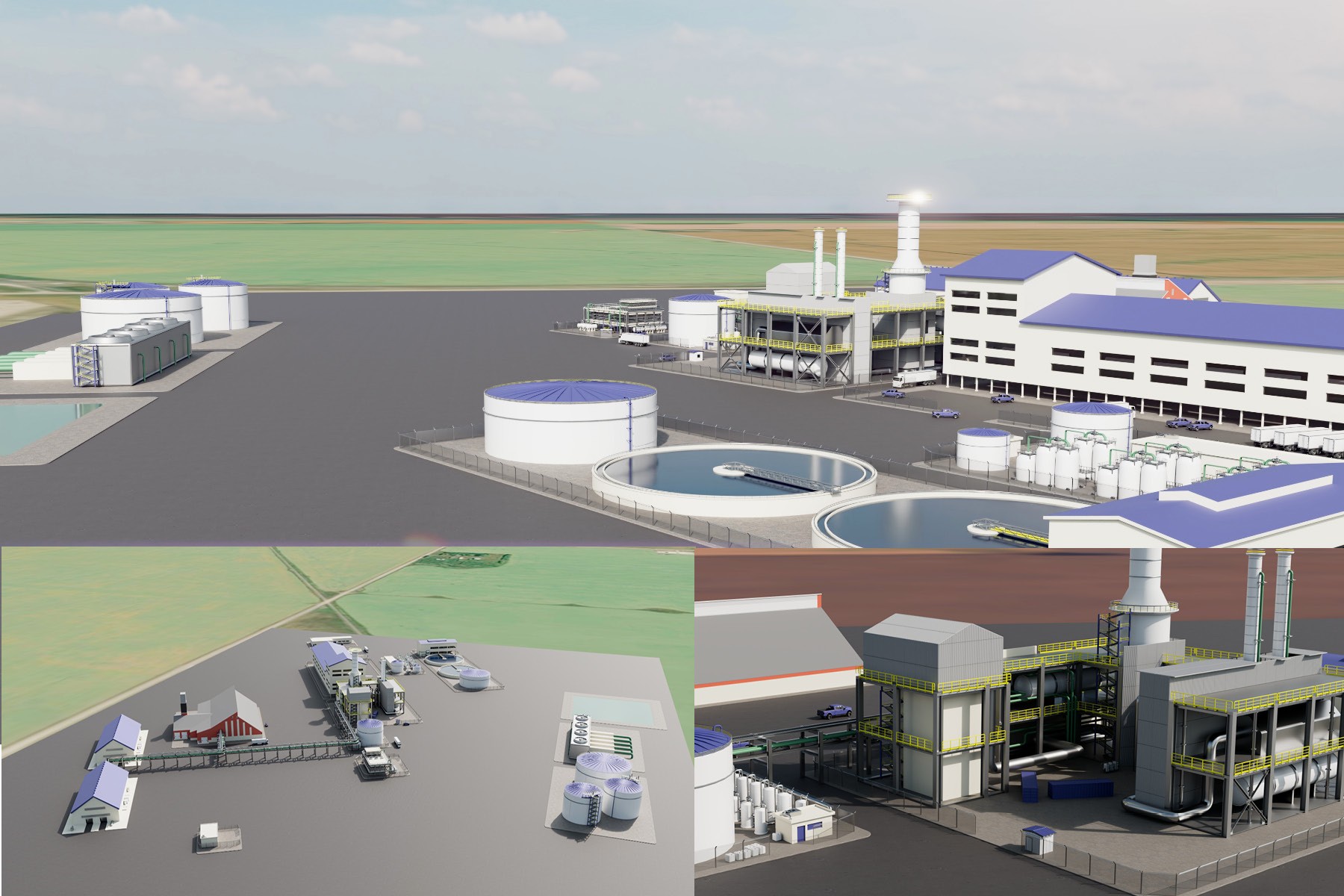

The facility will produce 1,500 metric tons per day (mtpd) of ammonia, 2,600 mtpd of urea/UAS granulation, and Diesel Exhaust Fluid (DEF) for cleaner emissions.

To achieve these goals, Genesis Fertilizers has partnered with leading industry innovators, including:

- thyssenkrupp Uhde – Advanced ammonia and granulation technology for increased efficiency and reduced environmental impact.

- Stamicarbon – NX STAMI urea synthesis technology, featuring next-generation reactor designs and energy-saving innovations.

- CARBONCO and Whitecap Resources – Experts in carbon capture and storage, enabling the sequestration of up to 800,000 metric tons of CO₂ annually.

“Genesis Fertilizers is not just building a plant,” says Mann, “it’s building a long-term solution for farmers by securing a stable, farmer-owned fertilizer supply for generations to come.”

Countdown to construction

With a planned start of commercial operations in 2029, Genesis Fertilizers is currently in the Front-End Engineering and Design (FEED) phase of the project. DL Engineering & Construction, a South Korean firm specializing in fertilizer plants, has been selected to conduct this work. DL brings extensive experience in engineering, procurement and construction for ammonia plants. To ensure best-in-class execution, DL and Genesis Fertilizers are collaborating with PCL, one of Canada’s top construction firms.

“The FEED process is critical to ensuring all aspects of the project align and make sense for all involved,” says Mann. “At Genesis, our job is to raise capital and work with farmers to advance this project. Early adopters who understand the benefits of vertical integration have already signed on, and more are joining as they see the project advancing through the required stages of development.”

Once all project metrics have been finalized, construction is expected to begin in 2026. The next phase, set to launch in 2027, includes the development of seven distribution centers that will source, store, blend and distribute fertilizer directly to farmers. The plant production facility is expected to generate over 1,500 construction jobs and support 180 permanent operational roles.

“Over the last two years, we have been focused on laying the foundation for advancing the Genesis project and ensuring all key components are in place,” says Mann. “Now, with a clear timeline, the next phase is all about execution. We invite farmers to take action and be part of this project.”

To learn more, visit genesisfertilizers.com.