As Canadian farms grow, so does the demand on the equipment needed to work on them, and that includes the tires. A bit of care and maintenance on where the rubber hits the road — or in this case the soil — can pay off in longer tire life and higher machinery efficiency.

Know your equipment

Tire maintenance should start when the equipment is delivered. The tires will be inflated at an appropriate level for shipping, which will likely be more pressure than needed for the work on the farm.

Read Also

Fertilize the crop, not the atmosphere

There’s a lot of interesting science about how nitrogen behaves in the soil. If you have a techie disposition, you’ll…

“It’s not like a passenger vehicle where the weight and loads are pretty consistent. In farming there could be two or three optimum pressure levels depending on the work that they’re doing and the implement that they are using,” he says.

“The big thing to remember with pneumatic tires is that the air does 90 per cent of the work. That is how important proper tire pressure is.”

Mike Pantaleo, Michelin North America

The producer can then consult the manufacturer’s tables and the dealer to ensure the equipment is running at an optimum pressure.

“Some folks think they can just choose a pressure and they’ll be fine. Michelin, for example, is known for being able to run on low pressures. But the optimum pressure is dictated by load and speed,” Pantaleo says. “Field conditions don’t make that big of a difference. The optimum pressure is the same whether the field is wet or dry.”

The correct tire pressure will reduce field compaction and improve fuel efficiency, traction, ride comfort and tire wear.

Tire tread

“It doesn’t always mean it is time to replace a tire but if the customer sees something that doesn’t look right, ask the question. Get it answered and have some peace of mind,” Pantaleo says.

If the treads are worn, the tires will be more susceptible to punctures, traction problems and reduced fuel efficiency.

Irregular wear may be an alignment issue — which can result in tremendous accelerated wear. Although there is a cost, it may be worthwhile to rotate tires from side to side to protect the investment.

“One example we see relates to rural road crowns which may cause issues on one side of the equipment tires and not the other. In this case, rotation would help to even out the wear across all tires,” Pantaleo says. However, don’t want to wait too long, as irregular wear won’t repair itself, so it is important to get ahead of it.

Under or over inflated?

Over-inflated tires can cause excessive soil compaction that can harm healthy root development, as well as result in a less comfortable ride due to bouncing and vibration. Too much air pressure can also increase tire slippage, causing excess fuel consumption and excessive wear on both tires and machine.

The footprint is smaller when the tire is overinflated so the wear is not evenly distributed. There is more load on fewer tread lugs and they are more susceptible to impact as there is less absorption. The dampening effect is limited.

Under-inflated tires can lead to problems as well, including irreversible damage to tire casings, tire failure, excessive wear during road travel and difficulty in maneuvering at field speeds.

Regular pressure checks

It’s important to check tire pressure regularly — the tire industry’s rule of thumb for a typical passenger tire is that for every 10 F (5.5 C) change in temperature there is a change of one psi in pressure. In agricultural tires the size and volume is much bigger and the changes are more significant. In Canada, this clearly can cause wide pressure fluctuations and is something to keep an eye on, especially if running equipment on a very low pressure.

“One thing I should stress is to never let air out of a hot tire,” he says. “For example, a truck tire starts the day at 80 psi but should be at 100 psi. If running underinflated during operation the pressure could go as high as 130 psi. So you come off the road and check the pressure and let out 30 psi to get it where you want it — 100 psi. The next morning the tire pressure will likely be 50 psi.”

Exciting new technology

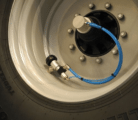

Central Tire Inflation System (CTIS) technology is gaining momentum. CTIS constantly monitors and adjusts pressures as needed through the day.

Ideally, equipment should run at higher pressures on the roads between fields and then at different pressures for fieldwork, but constantly making those changes is difficult, time-consuming and not practical on large farm tires. But CTIS makes those changes practical.

“It has been around for years and is broadly available as an after-market option. Some equipment manufacturers are now including it as an option on their newest equipment,” Pantaleo says. “We are very supportive of this technology because it will make a major difference for our customers. It is the way to go.”

Maintenance is key

To get the maximum life out of your tire investment and maximum efficiency from your equipment, always follow a specific tire-maintenance plan. Keeping your tires at optimum pressures for the application and loads will ensure maximum equipment efficiency, lower fuel costs, less compaction and longer tire life.

Pantaleo wants producers to know that there is a great underutilized resource available to farmers.

“Don’t be afraid to reach out to the tire manufacturers. Even though we don’t sell directly, we want to work with our customers to ensure they are getting the most from their equipment and their tires. Many people don’t know we will come out to them and help them develop a tire-maintenance plan at the farm or business.”