RED DEER, Alta. (Staff) – In a business where a pair of custom-made ostrich boots costs as much as $1,500, finding flawless leather can be like panning for gold.

During the recent Alberta Ostrich Breeders Association annual meeting, Brent Hepting of Maverick Tanneries at Unity, Sask. said he doesn’t see many top grade ostrich hides.

“The condition of the skin coming in is critical,” said Hepting, who estimates about five percent will grade number one.

Perfection sought

Like all tanners, Maverick wants large, unblemished hides from healthy birds. Downgrading occurs when the hides are marred by scars or nicks from a skinning knife.

Read Also

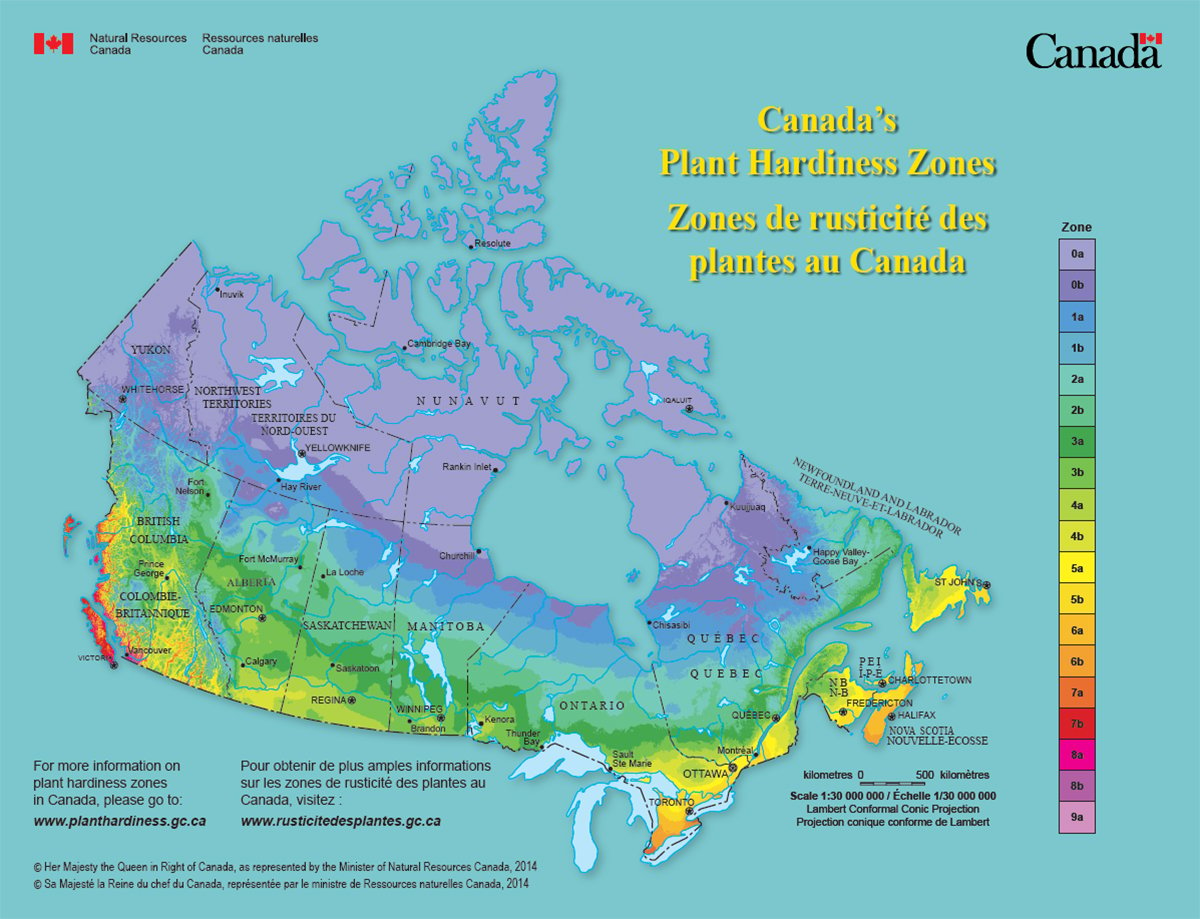

Canada’s plant hardiness zones receive update

The latest update to Canada’s plant hardiness zones and plant hardiness maps was released this summer.

Receiving about 20 green skins per week, Maverick’s staff removes feathers, as well as scraps of fat and flesh by hand.

Hepting recommends carefully plucking feathers as soon as birds are unconscious at slaughter time.

If that isn’t possible, feathers can be clipped at about two to three centimetres above the follicle.

Legs should be skinned from the backside to preserve the front middle of the leg. The leather from the legs has a scaled, reptilian appearance.

Blood and fat must be cleaned off. Blood stains can limit color choices and fat leaves grease spots.

Avoid metal

To preserve hides for shipping, place them in a saturated brine solution for 24 hours. Remove and drain. Hang over a wooden horse or pole. Do not let the hide touch metal. Salt the flesh area again. Keep skins in a cool place and avoid letting them dry out.

Fold the skin flesh to flesh and ship to the tanner in a burlap bag if possible. If a plastic bag is used, leave the top open or puncture the bag to allow air in.