VIKING, Alta. – An Alberta Hutterite colony has turned the manure from its hog and chicken operation into water, heat, electricity and a new cash crop.

The Iron Creek Colony, south of Viking, has eliminated its yearly $100,000 manure injection and $250,000 electricity bills, reduced its $60,000 water bill, cut its heating bill in half and earned $110,000 selling power to the provincial power grid – all from manure.

But one of the biggest benefits can’t be measured in dollars, said colony secretary Andy Hofer. The overwhelming smell from the colony’s 600-sow, farrow-to-finish operation, 650 ewes and offspring, 5,000 broiler chickens, 2,100 layer chickens and 1,000 head cattle feedlot has been drastically reduced.

Read Also

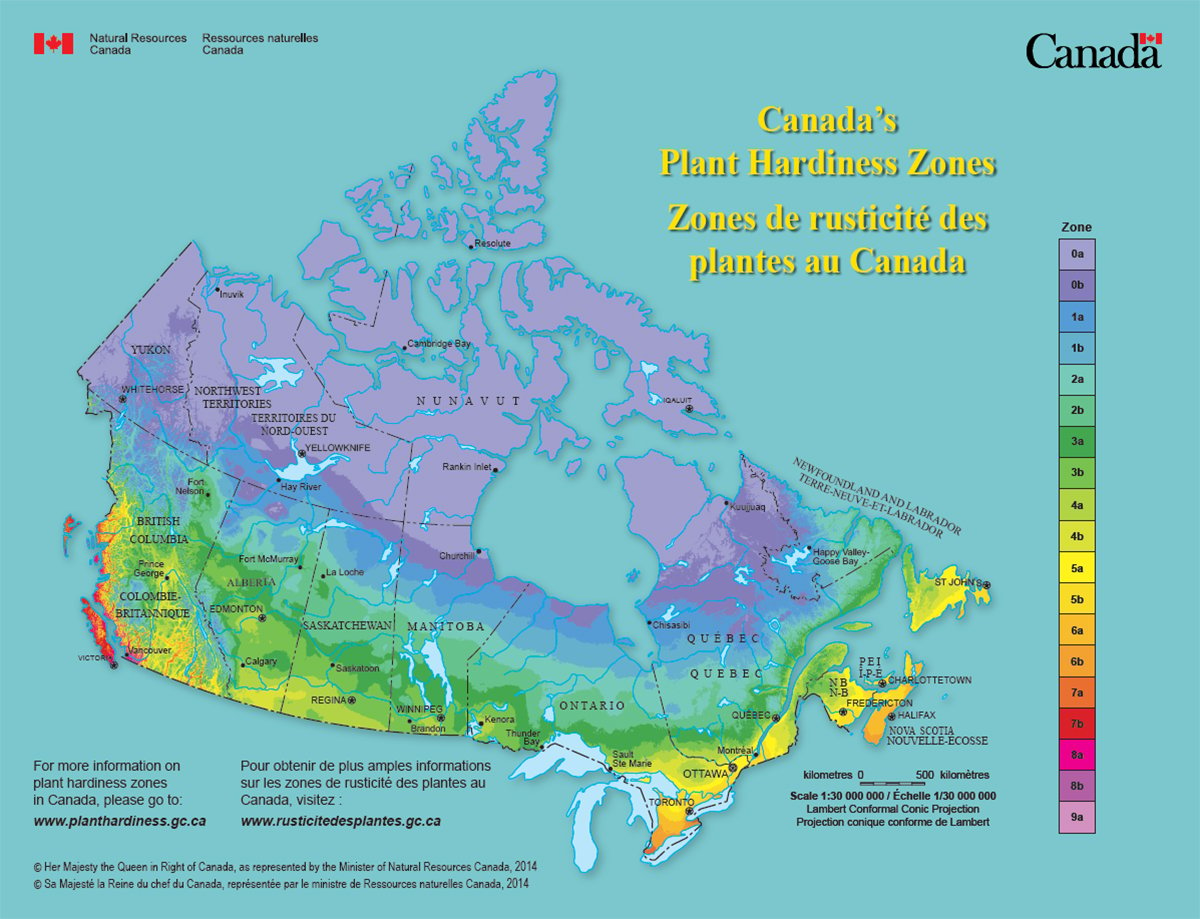

Canada’s plant hardiness zones receive update

The latest update to Canada’s plant hardiness zones and plant hardiness maps was released this summer.

“We don’t have the smell any more,” Hofer said.

The increasing price of electricity and natural gas, mountains of manure and a shortage of water for both people and livestock made the

$2 million project feasible.

Grant Meikle, vice-president of marketing for BioGem Power Systems, which built the power generation system for Iron Creek, said every large intensive livestock operation in the province may someday have a biogas system. He said it could be a way to deal with the manure created by Alberta’s two million hogs, 6.6 million cattle and 12 million chickens.

“I feel we have the solution for intensive livestock producers,” he said.

“Biogas recovery reduces smell by 80 percent.”

Meikle’s company bought the North American rights for the technology from a European company that already has 130 biogas energy systems operating around the world. In Europe, several smaller farms or villages share a single methane generator.

Meikle said he believes the Iron Creek electrical generator is the first commercial biogas system that makes methane from manure and sells electricity onto a power grid.

The colony can stop electricity generation, depending on the time of day and the price of power. Production from the 350 kilowatt-per-hour generator is “cranked up” between 6 and 9 a.m. and 6 to 9 p.m., when there is peak demand for power across the province and power prices are high, said Paul Hofer, colony farm boss.

On this day, production at midday hovered around 204 kilowatts each hour. Of those, 130 kilowatts were going onto the provincial power grid and the other 74 kilowatts were being used by the colony.

A side benefit of the methane gas is the production of recycled water. By spinning off the solids and putting the water through a cleaning and purification system, the process recovers 70 percent of the water fed to the livestock.

Now the plant produces five gallons of water a minute, but when the purification system is operating at full capacity it should produce 20 to 25 gallons a minute, better than many prairie farm wells.

By using the recycled water for livestock and cleaning, Hofer thinks colony wells will be able to once again keep up with domestic demand.

“The way it’s turning out with the drought and the water problem, water is going to be the most important benefit of this.”