The weather that has provided perfect growing conditions for forages in many areas this year is also causing concern about hay and silage conditions, especially for sweet clover.

“Sweet clover is notorious for taking extra time to dry due to its succulent stem,” said Bob Klemmer, livestock agrologist with Saskatchewan Agriculture in Weyburn. Add to this the warm, wet and humid weather, and drying times in the swath become even longer.

This may result in one or two serious problems: any forage that is slow to cure or wilt has an increased chance of exposure to damaging rain and of developing moulds and other spoilage organisms.

Read Also

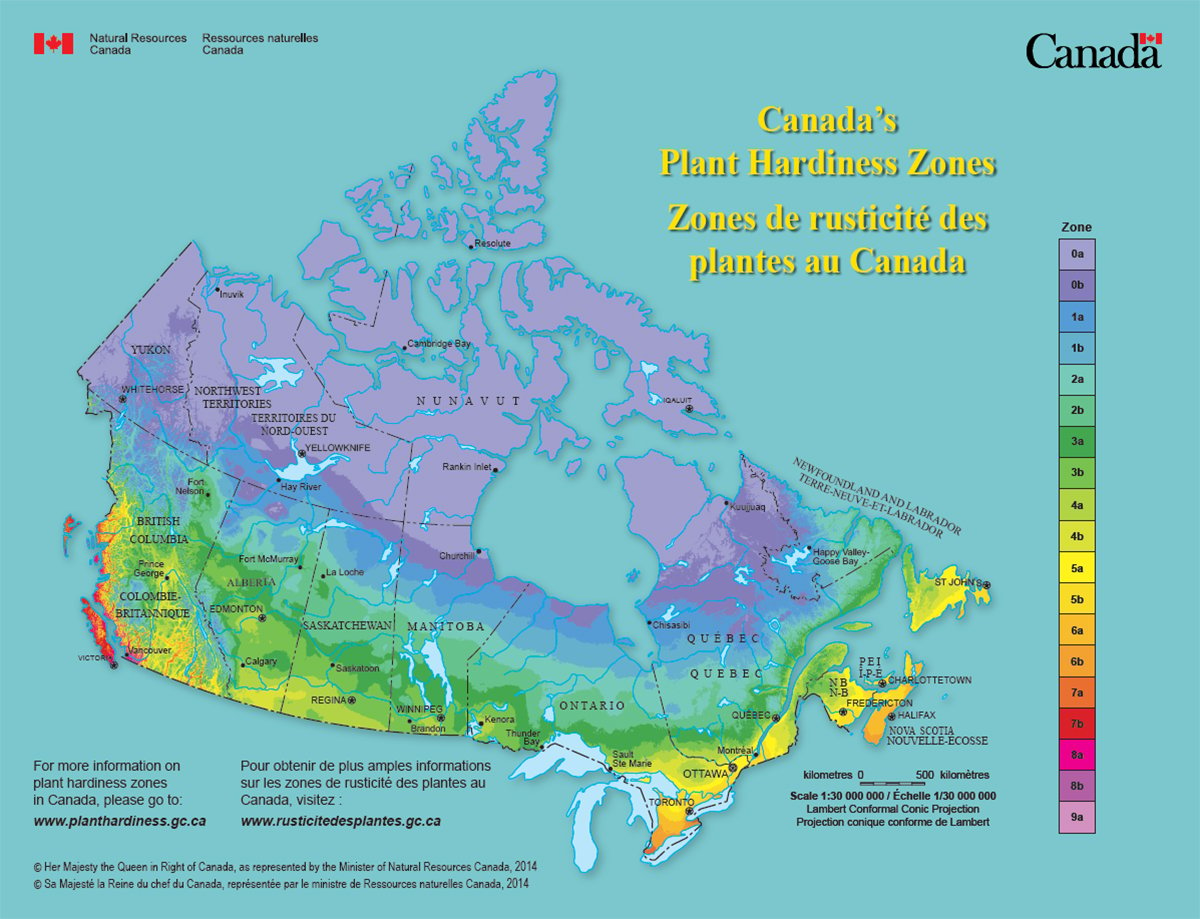

Canada’s plant hardiness zones receive update

The latest update to Canada’s plant hardiness zones and plant hardiness maps was released this summer.

“Spoilage can be significant with any forage, but it is especially a problem with common variety clover, which contains a compound called coumarin,” Klemmer said.

Due to the action of moulds growing on sweet clover during curing, wilting or storage, coumarin can be converted to a compound called dicoumarol, which is toxic to livestock. It is responsible for sweet clover disease or bleeding disease in cattle and, to a lesser extent, in sheep and horses.

“Producers who planted certified Norgold sweet clover seed need not be concerned because Norgold is a variety that was bred to contain low levels of coumarin. But, because the ditches are full of wild sweet clover, that readily crosses with Norgold, this low-coumarin characteristic is lost rapidly in later generations of seed. Common seed, which is widely available and commonly grown, should not be considered to be low cou-marin, even if it was grown from certified Norgold seed,” Klemmer said.

“Special care must be taken when harvesting sweet clover this year. The clover must be well cured, including the hard-to-dry stem, before baling. Producers should keep in mind the fact that the various types and sizes of bales have different recommended maximum moisture levels.”

Small square bales may be baled at 20 percent moisture, while soft-core, large round bales should not be more than 18 percent moisture, and hard-core large round bales should be no more than 16 percent moisture. For good silage production, packing and sealing to exclude oxygen is critical.

“Fast wilting, proper moisture and adequate packing is necessary to reduce spoilage to a minimum.”

Consider drying time

Klemmer said producers should also take note of conditions at the time of harvest. If they are right for mould growth – moist or humid, resulting in long drying times – precautions can be taken in the fall.

“Sweet clover with some spoilage does not necessarily mean that dicoumarol is present, just as lack of visible mould does not ensure that dicoumarol is not present. The only way to be sure is to test for dicoumarol before feeding,” said Klemmer.