AIRDRIE, Alta. – The days of spraying manure in a random sweep across the field are long gone. Today, spreading manure has become a science.

“The basic challenge is to use the manure as a nutrient resource,” said Shabtai Bittman of Agriculture Canada.

“All the methods of application should be geared towards using that manure effectively.”

This philosophy was emphasized during a recent manure management conference in Calgary, attended by more than 400 producers and scientists.

Recognizing manure’s value as a nutrient-rich fertilizer, farmers also attended a field demonstration at Airdrie where they saw a variety of injection-type implements.

Read Also

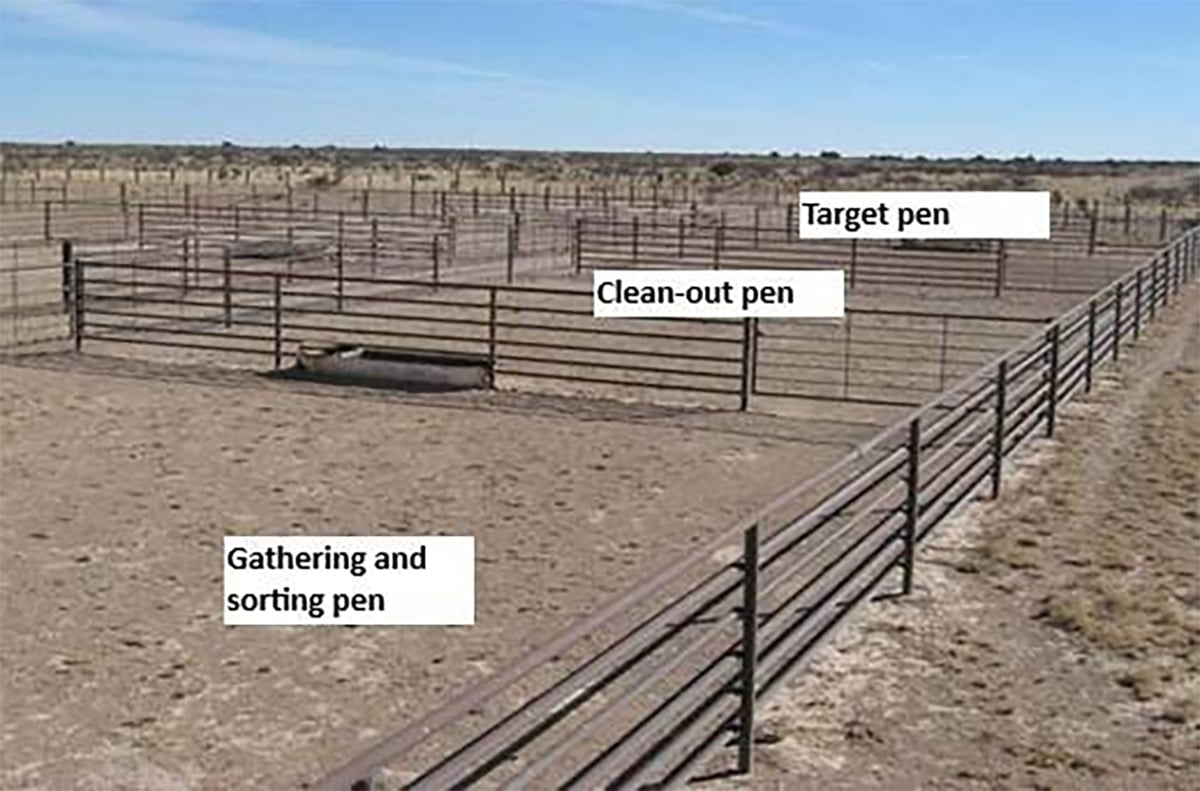

Teamwork and well-designed handling systems part of safely working cattle

When moving cattle, the safety of handlers, their team and their animals all boils down to three things: the cattle, the handling system and the behaviour of the team.

Each implement is designed to preserve nitrogen-rich ammonia, reduce odor and provide uniform application.

A common problem occurs in manure application when producers forget where the last load of manure was spread. The result can be double application and a burned crop.

New machines try to eliminate the problem.

Farmers also demand low cost, easily maintained equipment that can handle a variety of field conditions.

Injecting manure or laying it close to the ground helps reduce ammonia loss. This is the first compound plants respond to.

When applying manure with any of these machines, the delicate balance between nitrogen and phosphorus must be considered.

Manure contains twice as much nitrogen as phosphorus. However, plants use about 10 times as much nitrogen.

“You’re always applying too much nitrogen and not enough phosphorus,” Bittman said.

This must be monitored with soil tests after application.

Injection and application equipment comes in all designs and sizes.

- A dragline system pulls a large hose across the ground. The unit pumps manure direct from the lagoon to the applicator rather than trucking manure across fields and roads.

However, this is an expensive system and requires big fields to make it most effective. It can spread about 1,000 gallons of liquid manure per minute or about one million gallons in 24 hours. It works well on grass with a noticeable response from plants within a week.

- Sher-Dan Enterprises of Airdrie injects liquid manure from a custom built truck unit. It can spread 7,000 gallons per acre traveling up to 15 kilometres per hour. This is a high disturbance unit designed for cultivated fields. It sends the manure straight into the ground with little odor.

Hydraulics adjust the flow rate and tests can be done on the ammonia and nitrogen content.

- A Bourgault unit can apply up to 15,000 gallons per acre to a 20 centimetre depth. The injector is a coulter mounted on a tool bar. It causes minimum disturbance and can be used on direct seeded land or forage. Odor problems are minimal.

- German-made Aerway applicators have a series of knives on wheels that punch holes into the ground. The manure comes down hoses and infiltrates the soil via the holes. It works well for direct seeded fields and forage land. It has a shut off device and can deliver up to 7,000 gallons per acre.