Lloyd Quantz confesses that he has always hated building fences.

Seven years ago, he started working with engineers to build a mechanized unit that uses pressure and vibration to push pine posts into the ground. The same unit then drills evenly spaced holes into the posts and threads high-tensile wires for a long lasting, secure fence without staples.

His company, Greenedge Precision Fencing Ltd., has a patent pending for the system.

“Our patent deals with the multiple drilling, threading and fence building process,” said the rancher and entrepreneur from Didsbury, Alta.

Read Also

More work wanted on removing red tape

REGINA — Canadian farmers risk falling further behind competitors if two main federal agencies don’t become more efficient and responsive…

Quantz wanted a long lasting and easy to build fence with less maintenance and enough strength to withstand pressure from livestock leaning against it or trying to escape.

“Fences have just been a tribulation for people with massive amounts of repairs after the first 10 years,” he said.

With the new system, a two person crew can finish one and a half kilometres of fence in a day or install about 300 metres per hour with a five to six wire fence.

New wire is unrolled as the fence is installed under controlled tension using the weight of the rolls. The drills and threader can be adjusted up to seven wires on various spacings. If a wire breaks, a new one can be threaded through the hole. The biggest challenge was figuring out how to thread and dispense the wire.

“One of the things that amazes me is how simple it turned out to be and how complicated it looked from the beginning,” Quantz said.

His company has built a prototype and is now manufacturing machines with modifications.

The company started driving posts and building fences last October, installing fences on Quantz’s farm and for the Municipal District of Rocky View and private ranches in central and southern Alberta.

He said the best feature is that the fence is easy to electrify.

“Because of what is called a return ground system on our fences through our anchors, we think we beat some of the problems that the Prairies have had with electric fencing,” Quantz said.

“The National Research Council has really liked the project and would like to see us get better alignment tools and automation like GPS.”

Another feature is that the posts are driven with 6,000 pounds of pressure in less than a minute.

“On a vibrator, the key thing is amplitude of stroke and we have probably got one of the biggest amplitudes in the business, as far as we can see. A post has a certain spring factor to it and we have matched the spring factor to the vibrator.”

This kind of fence does not demand evenly spaced posts but rather matches the terrain to where posts should go. It is laid out more like power or telephone lines to make sure posts are anchored properly on slopes and dips along the ground.

Wire tension for winter and summer is taken into account.

“Typically fences are 150 to 200 lb. of tension per wire and so we think it is necessary to have a very good spring system to let that expansion in the summer and contraction in the winter,” he said.

“Our spring system has 12-15 inches of travel from summer to winter.”

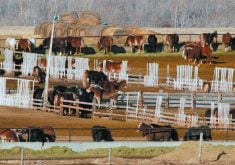

Quantz recommended this style of fencing for producers who keep cattle and horses together or those wishing to fence along river sides that need their fence to curve easily.

The system also accommodates producers using rotational grazing so they can electrify fences and add smaller cross wire fences to divide into grazing cells.

Quantz had tried systems from New Zealand and Australia. While many of the features were good, there were problems keeping tension on the wire because of the extreme prairie weather. Corner posts would pull out and the winches were finicky when it came to adjusting for summer and winter.