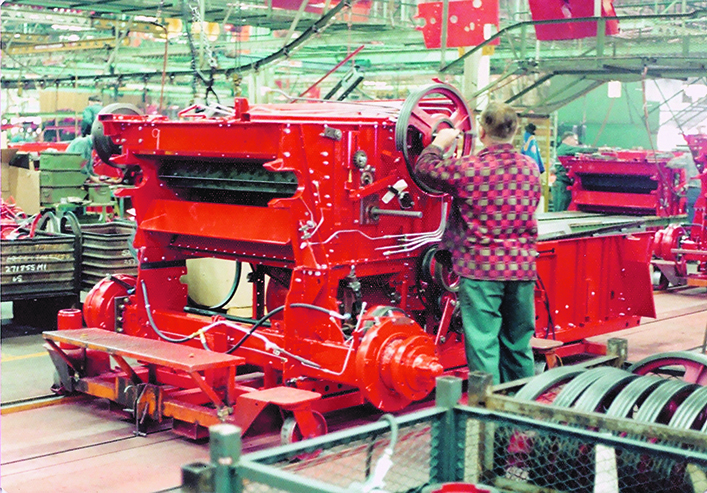

Massey Ferguson engineers had a reputation for being unconventional while producing combine concepts

In part three of this four part series, we take a look at what it was like to be a combine field test engineer for Massey Ferguson back in the 1970s. Here is a compilation of recollections from various engineers who worked at MF’s Brantford plant during that time.

Whenever a brand develops a new machine concept or model, a key step to making it production ready is putting a prototype through a rigorous field testing process, accumulating as many working hours on it as possible in the shortest time. That is how engineers ensure the design is ready for production and delivery to dealers for sale.

Other stories in this series:

- A look back at a Massey Ferguson milestone

- Brantford plant supported harvest brigade

- Final years of Massey Ferguson’s assembly plant

During the 1970s, Massey Ferguson engineers turned out a wide variety of concepts for testing, and some field engineers had a reputation for being unconventional in their methods. In fact, there is an infamous story that circulated in the ranks of the engineers at MF during that era of an engineer from the early days of the company who particularly embodied that attitude.

This particular engineer, along with his crew, were working out of an airport hanger while field testing a combine. This engineer decided the machine needed to be bigger; so they put it in the hanger and cut it in half to widen it.

We can’t say now if that was myth or reality, but it was widely circulated among the MF engineers at the time.

That same pioneering attitude reflected itself in some of the projects that were on the drawing boards at MF in the 1970s. A prototype 700-series machine was created that used a tandem-axle drive system, the same as a road grader; and another looked at the efficiencies to be gained by using two smaller, six-cylinder engines rather than one large motor. One would power the threshing mechanism while the other drove the machine. From a marketing perspective, it had little chance of success; however, it went through field testing.

As you’d expect, at that time other manufacturers were developing concept machines as well as new components and using farmers and custom operators to test their machines, too, often in the same part of the country.

Sometimes MF’s engineers would find themselves staying in the same motels with some other company’s engineers while they each worked on their own secret projects. And finding out just what the competition was up to was the sideline activity of engineers from all the companies. Word would eventually get around as to who was doing what in the area.

On one occasion in Arkansas, a group of MF’s engineers heard about John Deere’s engineers working in the same area. One Sunday morning they hired a man who had the local accent and a pickup truck. Massey engineers always drove white pickups and Deere engineers knew it.

This fellow had an old beat-up truck with a dog in the back. With three of MF’s engineers riding along, the local man drove into the yard where Deere’s test machines were sitting and struck up a conversation.

The MF engineers didn’t open their mouths for fear their accents would give them away. The Deere engineers were working on a cutter bar with broken pieces all over the place. Nonchalantly wandering around, the engineers had a chance to watch the Deere engineers struggle through a repair. Then they left, apparently leaving the Deere engineers unaware they were spied on.

But turnabout is fair play. And despite the fact that MF, too, tried to keep its test machines well hidden from onlookers, they weren’t always successful either.

In the days before digital photography, the Polaroid camera was the easiest way to get quick pictures. When MF’s engineers came out in the mornings and found the little white strips of paper on the ground from Polaroid pictures, they knew the competition had been looking around the night before.

The crew of the MF Harvest Brigade that followed custom harvesters on the annual route from Texas to Canada and supported them with parts and service didn’t focus on using them to test machines but other engineers did.

Getting a custom cutter operator to take prototypes and put a lot of hours on them was critical in perfecting the design of new combines for all the manufacturers. That was the only way engineers could put several years’ worth of work on a machine in just a few months.

On one important occasion that arrangement worked to the advantage of both MF and the cutter.

MF had given some 760 models to a custom cutter, but he really wasn’t interested in using them. The cutter only had to supply the fuel and operators to use them. But despite that, the combines were sitting idle.

MF staff made the decision to collect their machines and give them to another custom operator: Sam Wiggins, who had been struggling with some older 510 combines. He took advantage of the MF offer to give him the 760s.

Wiggins parked his own machines and ran the 760s non-stop. The next year when the 760 went into production, Wiggins bought a large fleet of them. He would go on to become the biggest custom cutter in that area, thanks in large part to the use of those original 760s. That started a long-term relationship between Wiggins and the MF engineering staff, who went back to him year after year for testing.

In the next instalment we’ll focus on MF’s development of a rotary model and the beginning of the end for the Brantford assembly plant and MF’s entire combine manufacturing days.