The Ag in Motion farm show offered an opportunity to see the variety of seed drill openers on the market in Western Canada. In this series, we look at the choices for seed and fertilizer placement, different opener designs and other new equipment features introduced for the next growing season.

With many systems, altering input application across a field using prescription maps requires changing application rates across the entire drill each time.

Morris 10 Series carts can now make input changes across each metering section, allowing for more precise applications.

Read Also

Fall rye hits record high in Manitoba

Winter cereals 2025: More Manitoba fields grew fall rye in 2025 than ever before, but winter wheat slipped and, while spring stand survival was good, drought took its toll

“With the electric drives, we can now do variable rate by section,” says sales and marketing manager Garth Massie.

“With the last series (air carts), when using the variable rate maps, the satellite receiver on the tractor is going to decide what zone you have across a 70-foot, if it’s a 70-foot, machine, whereas this one will do a variable rate by section. And our sections are in that seven- to nine-foot range.”

When the initial models of the 10 Series carts were released to a few farmers during the R&D process, that feature proved even more popular than the company expected.

“We rely on farmer partners to help us test equipment before it comes to market,” Massie says. “We call that a stage release. I was a bit surprised by the number of farmers taking the variable rate by section.”

Growers also liked the load cells on each tank, which gives operators another way to confirm the drill is seeding at the proper calibrated rate.

The 10 Series carts, introduced earlier this year, include three models available in tow-between and tow-behind configurations. They replace the 9 Series air carts.

“Our 9 Series air cart was a soldier for us, but it’s been around for over 11 years,” Massie says. “There are three (10 Series) models, 660 bushels, 820 and 1050.”

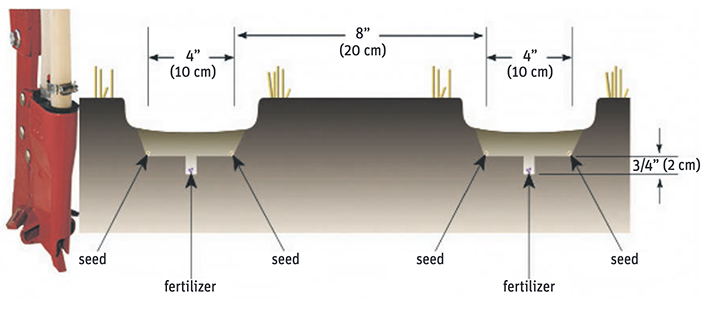

The carts can be paired with Morris’ C2 Contour or Quantum drills. The most popular opener on those drills is Morris’ own paired-row style.

“There are agronomic benefits with that. It’s more competitive with weeds,” Massie says. “You have two bands of seed, each two inches from the centre. The fertilizer is placed centrally, three-quarters of an inch below.

“We’ve done quite a good job of placing them separately. That allows for high rates (of fertilizer) and rate flexibility.”

It also allows for a high rate of seedbed utilization, helping crops outcompete weeds.

Opener linkage continues to use the brand’s one-to-one contouring ratio, which Morris first brought to the market several years ago.

“Morris introduced that into the market first and we’ve stuck with it,” Massie says. “It’s the best for holding its depth, particularly in hilly land.”

With the wider furrow of the paired-row openers, Morris drills use wider packing wheels than most others.

“Because we’re placing our seed in those two-inch bands, or even with the side band that goes two inches to the side, we need a packer wheel with overlap, so we have to be wider than a traditional four-inch packer wheel,” Massie says. “So, you’ll see a lot of five and a half inch.”