The title of John Patience’s presentation to the Saskatchewan pork industry symposium was “tactics and strategies for maximizing net returns from the sale of market hogs.”

The first thing he told his audience was that maybe that title should be amended.

“I should probably change it to minimizing net losses, not maximizing net returns,” he said with a rueful smile.

Hog producers are losing money with every pig sold because low hog prices, high feed prices and a strong Canadian dollar have hit the industry with a triple whammy.

Read Also

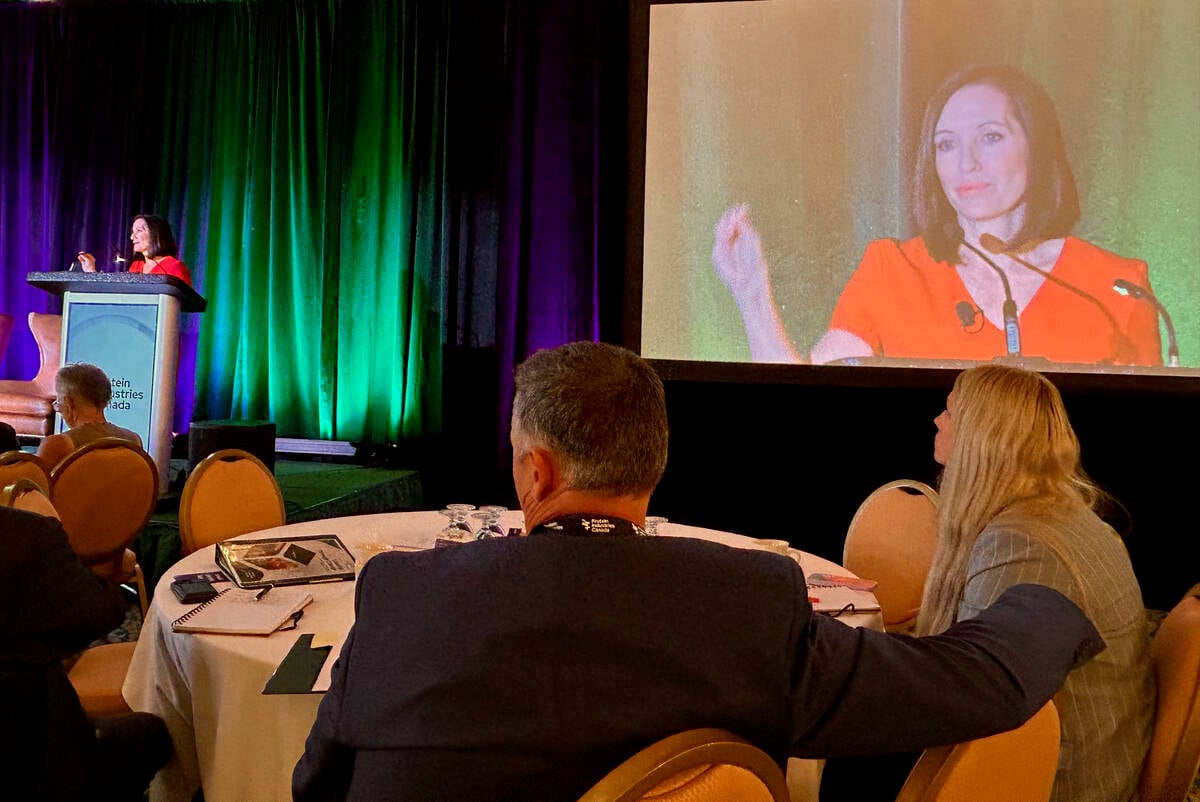

Canada told trade crisis solutions in its hands

Canadians and Canadian exporters need to accept that the old rules of trade are over, and open access to the U.S. market may also be over, says the chief financial correspondent for CTV News.

Patience, president of the Prairie Swine Centre, said while there’s not much that can be done about market prices or the exchange rate, producers can help their bottom line by watching their feeding regimes.

In October 2005, the average feed cost per pig sold in Western Canada was around $30. In October 2007, it was around $60.

“The key message is that there are significant dollars that are sitting on the table waiting to be taken up,” he said.

Patience presented the growers in the room with a list of 10 specific measures they can take to reduce their feed costs.

They included:

- Define the objective of the feeding program. Is it maximum return per pig, specific carcass characteristics, maximizing genetic potential or minimizing losses?

- Select the correct dietary energy level, which can reduce costs by $1 to $13 per pig.

- Choose the most efficient and economic ingredients for a feed formulation. For example, substituting corn for wheat, increasing canola meal and reducing soybean meal can cut costs by $4.72 a pig, based on current grain prices.

- Market pigs at the right weight. Getting 85 percent in the core weight range versus 66 percent can boost the return over feed costs by $3 per pig.

- Develop a feed budget and know exactly the feed intake of pigs on your farm.

If a producer implemented all the changes, Patience said, he or she could boost revenue per pig sold by $10 to $15.

However, he acknowledged not all producers would be in a position to do all that.

“There’s only so many hours in the day and so much labour available, so a producer has to look at his own situation.”

A “mom and pop” operation with one hired man might only be able to implement one or two of the changes, while a large business with a number of employees and specialists on staff will be able to do much more.

The simplest things to do, he said, are monitor feed intake, set a feed budget and track estimated versus actual feed use and adjust ingredients to produce the least-cost formulation.

Switching to a diet based on net energy concentration rather than digestible energy can help, but this requires a significant level of technical skill.