Eric Steeves says raising sheep on forages grown under thousands of acres of solar panels provided economic stability and perhaps even saved his family’s fifth generation southern Alberta grain farm.

It certainly wasn’t an overnight process, and it involved a steep learning curve, but Steeves says being involved in Canada’s largest renewable energy, solar power generation project has been a game changer, not only for his family’s Yetwood Farms but also for several other family farms in the Lomond-area, about an hour north of Lethbridge.

The system of grazing sheep (or really any agricultural activity) under arrays of solar panels is known as agrivoltaics.

Read Also

Trump’s tariffs take their toll on U.S. producers

U.S. farmers say Trump’s tariffs have been devastating for growers in that country.

For most, that is not a household term. Agri, of course, relates to agriculture, and voltaic (pronounced vol-tay-ick) refers to some process that generates electricity. Put them together and the term refers to producing an agricultural commodity under these solar fields.

Agrivoltaics is a relatively new concept to Canada but has been used with solar power generating projects in the United States and other parts of the world for many years.

The Steeves were just regular grain farmers, cropping about 6,000 mostly dryland acres of grains and oilseeds when they were approached in 2017 by Calgary based Greengate Power Corp., asking if they would make land available for a solar power project.

“I thought the first phone call was a joke,” says Steeves.

“Some sort of scam, as they were talking about a large solar project. There was a second call and I said, if this is legitimate, why don’t you come here and have a meeting with the people to properly explain the project.”

So they did. Starting in July 2017, the company met with several farm families in Lomond during a number of meetings, which resulted in contracts being signed in October 2017.

That was the beginning of the Travers Solar Project, “a trail blazer among solar power projects in Canada,” says Steeves.

The project itself, today the largest solar project in Canada, involved installation of 1.3 million solar panels in arrays covering about 3,400 acres of farmland. The Steeves family have leased about nine quarters, or 1,440 acres, to the project, while several nearby farm families leased another 14 quarters, or 2,240 acres, to Greengate.

It took about two years for the company to obtain all the necessary permits. Construction started in 2020, and the project was completed and producing power by late 2022. The $700 million project is designed to generate 465 megawatts of electricity, which in general terms is enough to power more than 150,000 homes.

So how did the Travers Solar Project benefit Yetwood Farms and the other producers who leased their land to the project?

First of all are the lease payments from the energy company.

Depending on the project, lease rates can range from $700 to $1,200 per acre per year. On top of that, if the landowners are contracted to look after vegetation control — keep the grass and weeds cut under the panels — that can be worth another $200 to $400 per acre per year.

“When we looked at the project, here we are farming in the Palliser Triangle — the brown and dark brown soil zone — and on average our net return from crop production would be around $70 per acre,” says Steeves.

“That’s an average. Some years better and during several years of drought conditions, we could collect crop insurance, which was less. Whereas on those acres leased to the solar project, a person can potentially earn from $900 to $1,600 per acre just to have the project there. We saw getting involved with the solar project as an excellent opportunity to diversify the farm. With mostly dryland crop production and years of drought, this project has perhaps saved our farming operation, along with other family farms in the area.”

But don’t these solar projects take good farmland out of production? That’s where agrivoltaics kick into gear.

When these large solar projects were first introduced in Alberta, for example, the asset owners wanted the bare ground underneath the solar arrays covered with forages. However, it was soon realized that the real risk to these solar panel arrays wasn’t hail, although that can be concern, but potential for grass fires that could wipe out the whole operation. Hence the need for vegetation control.

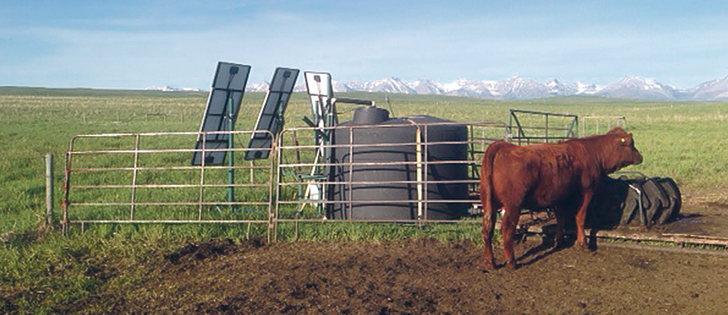

There could be mechanical means for removing the forages, but with spacing of 21 feet between solar arrays and only about four feet of clearance under the panels when they are in the table top position, mowing and perhaps even baling the forage for removal would require specialized equipment.

For vegetation control in other solar projects around the world, grazing livestock — namely sheep — under and around these solar panels was a common practice.

“My dad had raised pigs at one time, and we did run some cows at different times years ago, but I had zero experience with sheep,” says Steeves.

In preparation for providing vegetation control for the solar project under construction, Steeves bought 50 sheep in 2020. He wanted to get some idea of what it was like to manage the animals.

“I soon realized that sheep are a lot different than cattle, and for a project this size I was going to need some expert help with management,” he says.

Steeves did some research, located an expert on sheep, a professor specializing in small ruminant livestock, who was managing a ranch raising sheep and goats connected with the University of Mexico in Mexico City. He was interested in working on the Yetwood Farms project. In late 2023, he moved to Alberta and has been managing the flock.

Today, Yetwood Farms, which is managing the sheep and vegetation control for the entire Travers Solar Project, is running 2,000 breeding females. The plan is to increase that to 3,500 ewes over the next year and within five years grow the flock to about 8,000 head.

The family have built lambing facilities as well as a feedlot for finishing lambs. The plan is to manage the flock so it is producing lambs on a year-round basis. Lambs are finished to an average of 130 pounds and marketed through the Westpine Meats processing plant at Innsifail in south-central Alberta.

Steeves says when the flock is fully stocked, it has potential to produce about 13,600 lambs per year, with a total carcass weight of about 850,000 lb. of meat. If the price averages about $5 per pound, that meat has a total value of $4.25 million.

Along with land lease rates to farmers, agrivoltaics provides further return to producers through sale of agricultural commodities such as lamb.

Interestingly, the wool from the sheep has no value as a fibre.

The sheep are shorn annually, and all the wool, which is high in nitrogen, is mixed with manure, composted and applied to Yetwood Farms’ annual crop acres. The farm hires contract shearers to shear the flock. Shearers are paid about $6 per head. A shearer with proper technique can shear up to 30 sheep per hour.

While sheep are a very common commodity for agrivoltaics, Steeves says there are other options as well.

A number of research projects across Canada, including at Olds College, are looking at the potential to produce poultry, hogs, beef cattle, hay and even annual crops under properly designed solar projects.

The sheep flock at Yetwood Farms is managed in an intensive rotational grazing system.

The ground beneath the solar panels has been seeded to a forage blend.

Right now the flock is divided, with 1,000 head of sheep grazing on about 60 acres and moved weekly. As numbers increase, multiple flocks will move through the field of solar panels.

With rotational mob grazing, the Steeves are able to run two to two and a half sheep per acre for the grazing season. With more extensive grazing management in the early days, carrying capacity was in the 0.8 to one sheep per acre range.

Steeves says the farm did invest in a low-profile Avant 860i loader, which can travel between the arrays. It can be outfitted with a boomless sprayer to apply herbicide. For seeding, they also have a small custom built air seeder that works between the solar arrays.

“If we have bare ground, the air seeder is probably the best way to get grass established,” says Steeves.

“But in areas where we want to renew or add forage species, we found the best approach is to hire a drone applicator, apply the seed by air, then turn the sheep on to that area to graze. The hoof action of the sheep works the seed into the soil.”

Shade from the solar panels provides the sheep shelter from the sun and also creates a micro-climatic zone under the arrays, which suits forage production.

As they tried to establish forages during dry years in some areas, the kochia took over before the grass. Some areas of the pasture areas were at one time 85 per cent kochia and 15 per cent grass. However, through grazing management and seeding where necessary, those percentages have been reversed.

“We do have a couple areas of foxtail that we will address with herbicide, but for the most part forage production is trending in the right direction,” he says.

Steeves says the agrivoltaics project has been an intense learning experience.

“When we started nine years ago, it really was the wild, wild west,” he says.

“There were no guidelines or regulations. We had to learn this system from scratch, and we are still learning. There were a number of pain points as we went along, but the fact is that the benefits far outweigh any pain we experienced. It is a diversification opportunity that could benefit many farms.”