Thrive Honey is a story of perseverance on the way to sweet success in pollination services and honey production.

The Coaldale, Alta., business was showcased at a Farm to Table Tour sponsored earlier this summer by Alberta Sugar Beet Growers.

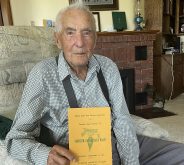

Coming off the heels of a previous business that did not work out, co-owner Landen Stronks was looking for other opportunities and joined forces with three brothers from Witdouck Farms to buy what was previously Kiwi Brian’s Honey in 2008.

Read Also

Favourite family recipes make fall meal planning easier

When everything is in a state of turmoil, keep meal planning and preparation easier by depending on family favourite recipes.

Already familiar with the leaf-cutter business, the group added honey bees, but the experience was not sweet at first. Leaf-cutter bees are more solitary, picking up nectar (and pollen along the way) to feed their larva. Honey bees need colonies to work together.

“We started wanting to buy 1,000 bee hives. Unfortunately, there’s a parasite called varroa, and it was at a level that was kind of difficult to manage,” said Stronks, managing director of Thrive Honey.

“In the spring, when we went to buy the business, the majority of the bees were dead, and that was attributed to varroa. That was a real rough start. We had to manage the relationship with the previous owner, and we wanted to continue to buy the business, but we needed to get the bees.”

Bee import opportunities from other countries are limited, and Thrive Honey eventually bought its start-up hives from New Zealand.

Those initial stumbles have since led to a 12,000-hive capacity at the company, which employs around 25 people at its max, with the majority being seasonal workers.

The main driver of the business is hybrid seed canola, which emerged in southern Alberta in the late 1990s to create a high demand for pollination services.

“From my understanding, there’s upwards to 80,000 honey bee hives that are brought in during the pollination season. The pollination season for hybrid canola would start anywhere around June 15, and until about this time of year (late August), things are starting to slow down,” said Stronks.

Thrive Honey starts its production season in late February/early March with early spring checks and feeding the bees pollen patties.

The bees are fed liquid sugar from southern Alberta’s sugar beet industry.

In April and May, Thrive Honey starts looking at the condition of the queen bees and monitoring disease. Twenty-four hour shifts can be necessary when hives are moved at night.

“If we move them during the day, then obviously all the forage bees that are out in the field are going to stay at the property,” said Stronks.

The company has winter hives as far as an hour-and-a-half away.

He said honey from the Prairies has a creamy texture, while the mountain areas of British Columbia such as Fernie have a more floral flavour.

Even with Thrive Honey being secondary to pollination services, the company produces numerous 600-pound drums of honey weekly. Five hundred to 600 bees are required to produce one drum of honey during production season.

Workers can get a workout with some honey boxes reaching 140 pounds, depending on density.

The temperature in the heating rooms reach up to 30 to 35 C, resulting in honey that flows easier from the frames.

The boxes are spun for five to seven minutes using extractor machines, and the honey eventually makes its way to the drums.

Stronks said 90 per cent of the honey is exported to eastern provinces or south to the United States through brokers, although the U.S. market is troubled at the moment.

“With the relationship with the U.S. right now, there’s lots of talk that they don’t want Canadian honey. The U.S. does not produce enough domestic honey, so they are a net importer. But, now what they’ve done is the U.S. has rallied really well for their domestic producers, and they pay them quite well. So if they’re getting $3 a pound, and then they supplement the rest with the cheapest honey they can find, which I would argue, or wonder if it’s even honey, and then they blend it to get the price point,” said Stronks.

“And so Canadian honey is high quality. It’s still cheaper than what the American beekeepers are getting paid, but it’s still higher than in India or China.”

Thrive Honey usually starts marketing its honey in thirds: near the end of summer, around Christmas and post-Christmas sales.

Although honey accounted for only 0.4 per cent of Alberta’s farm income in 2022, honeybees contribute billions to the agriculture sector on a national scale with their pollination services.

According to a 2024 CBC article, interest in beekeeping has been climbing in Alberta, with 620 beekeepers in 2008 increasing to 1,950 in 2023, the vast majority being commercial beekeepers.

Alberta produces approximately 40 per cent of all honey in Canada.