Bourgault Intelligent Control has been under development for five years and will debut in the 2026 model year

A new 100-foot 3545 drill was the centrepiece of Bourgault’s product launch in Phoenix, Arizona, in November, but the brand had more to talk about, including a new seed controller system developed in-house.

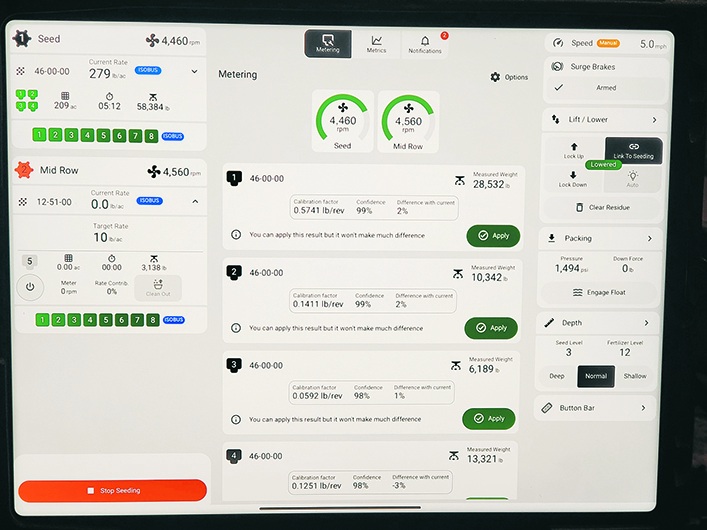

To feed the new 7-Plex drills and eventually Bourgault’s full line of seeding equipment, the brand will move away from the Topcon systems it has been using and introducing its own in-house system dubbed BiC (Bourgault Intelligent Control).

“This is a brand new technology for us,” said territory manager Jordan Henderson.” It’s a brand new wireless seeding controller. It’s an IOS-based app that’s taking us into the future with our seeding controller capabilities.”

Read Also

Herbicide resistance sprouts in Manitoba’s wild oats

Farmers across Manitoba this fall are gearing up for the latest salvo in what, for many, has become a longtime battle to beat out wild oats.

BIC has been under development for five years and in field trials for the last three.

“Fifty thousand acres have been seeded so far with this system, and over 100,000 by the end of next spring,” he added. “So, definitely not something that was built yesterday.”

The system is designed to work with a major brand tractor monitor’s controller, which will control some functions while the BiC system controls others.

“The biggest thing for us with this system was simplicity,” said Henderson. “We needed to get to a simpler, easier to use, more intuitive system. The biggest challenge we’ve had over the past few years was the complexity of the system and the learning curve.”

One of the features intended to make the system simpler is “product-centric seeding”, which focuses on the total rate of each product being applied, even if it is being drawn out of two separate tanks.

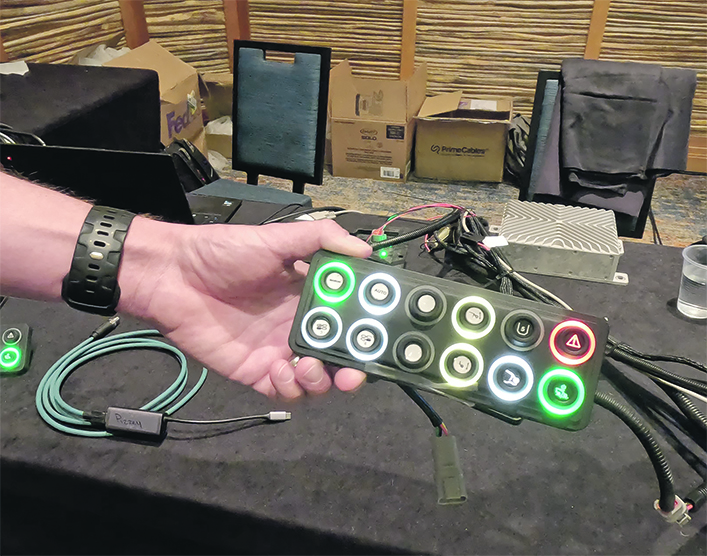

“There is also a button bar, because it can be challenging at times as you’re running through the field to find the right buttons with a tablet,” says Henderson. “We found our cooperators, once they were seeding, controlled all of the features through the button bar.”

To make the system easier to install in a tractor, the monitor is wireless, eliminating the need for extensive cable connections inside the cab.

“The ability to seamlessly interact with the tractor controllers means the data is going to be live-streamed, which is a big difference for us. There’s no more USB sticks. We know how important data is to our customers.”

BiC will be available in limited release for the 2026 season.