LANGHAM, Sask. — Derek Dery recalls parking the seeding equipment for the day, then pulling out a notepad to jot down the details of the day’s work in the fading light.

“You’re trying to write a story in the dark,” says the founder and chief executive officer of Sixteen Grains, a farm-to-customer operation near Saskatoon.

“We’ve grown our farm kind of strategically by picking up the land that no one else wants to farm,” Dery said.

Read Also

More work wanted on removing red tape

REGINA — Canadian farmers risk falling further behind competitors if two main federal agencies don’t become more efficient and responsive…

“That’s why we have fields that look like turtles and full of power lines — not very fun fields to farm.”

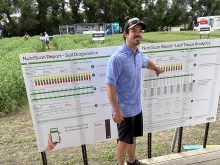

Dery participated in a three-farmer panel discussion at a presentation on Climate FieldView during last month’s Ag in Motion farm show.

Dery needed a better way to not only capture his data but make it easily available for later analysis to guide decisions.

Climate FieldView provides this solution. As a bonus, he says, the system provides the traceability data to help him build the farm’s reputation with supermarket customers that buy its pancake mix.

The irregular nature and tight margins of Sixteen Grains’ operation means more intensive management, which demands as much information as Dery can get his hands on.

“We make a lot of in-season decisions, and no farm is exactly alike for us,” he says.

“We’ve grown our farm from 1,000 acres in 2011 to seeding close to 9,000 last year. We don’t have great storage for that much grain. We don’t have the cash flow. So, we need to know what the crop is going to be so we can invest in capital such as bins or grain baggers.”

FieldView comprises a data module, or “puck,” which connects to the data bus on a piece of equipment and wirelessly connects to a tablet or smartphone. The software then augments this data with information on weather and conditions, whether they are from local stations installed in a field by the farmer or from public sources such as satellite weather data.

“The thing with agriculture is we’ve had all of this data and we haven’t had one place to house it,” says Troy Prosofsky, a FieldView rep with Bayer.

“The system not only gathers the data, but, with a bit of effort, allows monitoring of fields closely enough that if a farmer spots a difference in crop performance, they can go back and find out what was done to cause the anomaly.

“The GPS we have nowadays is bang on.”

Prosofsky says a bit of work is needed to get that level of precision, such as measuring each piece of equipment. Once that’s done, precise answers become possible.

“We can see if something’s off by six inches,” he says.

“The nice thing about it is if we seed a trial this way, we can actually harvest it this (perpendicular) way and it’s so accurate it will still give you yield results.”

Mark McNaughton and his brother run MDM Aqua Farms, a 3,500-acre operation near Rumsey, Alta., just north of Drumheller. While the “Aqua” in the name has become obsolete since they got out of the fish farming business, they continue with wheat, barley, canola and legumes. He marvels at how field mapping technology has changed over the years.

“Think of the technology that’s in the cab of your average piece of equipment compared to 10, 20, 30 years ago. It’s night and day,” he says.

“GPS, you push a button here and you’re within inches. Back when my dad had a sprayer, he dragged a tire around to see where he was going, right? On the back of the sprayer.”

The brothers embraced the power of data from the start, adopting and testing FieldView from its beginnings as an independent company through its acquisitions by Monsanto and then Bayer.

Initially, the McNaughtons were drawn by the ability to capture yield data, simplicity of use and the system’s brand-agnostic nature, which is an important feature on a farm that uses equipment from several different manufacturers. Efficiency and detailed record keeping are big selling points for their operation.

“It’s gotten better over the years and they’ve added a lot of features that were not there originally,” he says.

“So, we use it to record all of our, basically any field operation. So, whether it’s seeding, spraying, harrowing, just so we know what’s happening out there and we can go back and look at it.”

Because Fieldview tracks equipment-specific data, it can also spot problems as they arise. For example, McNaughton says if two combines are running at the same time in similar locations and getting significantly different yields, it’s time to stop and check the settings.

Niko Mayer grew up fixing equipment on his grandparents’ and uncle’s farms in Germany, getting his papers as an agricultural mechanic before moving to Canada about four years ago.

The 25-year-old has since expanded beyond wrenches to run the day-to-day operations of Le John Farms, a 10,000 acre operation north of Langham. About 40 per cent of the farm’s production is pedigreed seed sold through its Foundation Seeds arm.

FieldView has been a constant ever since he began.

“Ever since I’ve been here in Canada, we have used FieldView for every operation on the farm.”

While time management at seeding will always be a challenge — Mayer cites frequent rain breaks this wet spring — a data management tool is valuable to address another challenge: input costs and profitability.

“FieldView is very good for us in the form of we can use prescription maps and put fertilizer down where we actually need it,” he says. “That’ll be the challenge, to try and get your input costs down and your yields up.”

Detailed records also make it easier on the seed growing side, where great care must be taken to ensure no same-crop volunteers sneak into the field and bring down seed purity.

“We don’t want to grow the same barley variety in the field where we grew a different barley variety two or three years ago,” he says.

“So there, Climate FieldView, the technology now helps us to just keep track of everything to make sure.”

The same goes for chemical carry-over, or for analyzing crop performance. If a field or portion of a field is under-performing, going back through the data can tell the farmer what might have gone wrong. The FieldView system also allows farm managers to monitor their operations remotely.

“I’ve got some sprayers rolling today in fungicide,” Mayer says.

“After the show and before the show I was on my phone just double checking that they’re actually putting the right chemical down. And well, technology is only as good as you are. So I double check this.”